Nov 22 2001

DooDee Studio / Shutterstock

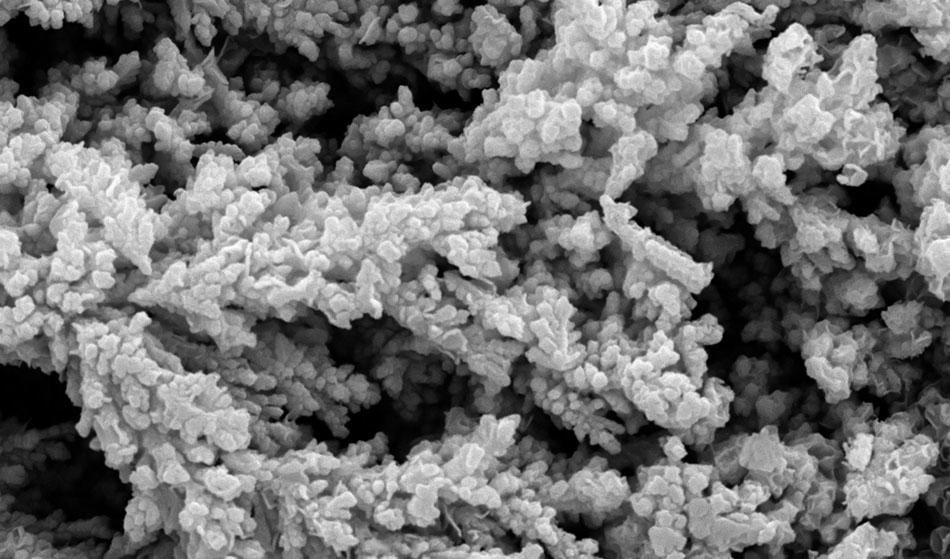

Nanomaterials, or nanocrystalline materials, have grain sizes on the order of a billionth of a meter. These materials have extremely useful and fascinating properties that can be manipulated for a wide range of structural and non-structural applications.

Putting Nanomaterial into Perspective

All materials contain grains, which in turn, contain a number of atoms. Based on their size, these grains are generally invisible to the naked eye. The grain size in traditional materials varies anywhere between hundreds of microns (µm) to millimeters (mm). A micron (µm) is a micrometer or a millionth (10-6) of a meter. The average hair of a human being is around 100 µm in diameter. A nanometer (nm) is a still smaller dimension than a µm (micrometer), a billionth (10-9) of a meter.

The grains in a nanocrystalline material are on the order of 1–100 nm. The average size of a single atom is on the order of 1 to 2 angstroms (Å) in radius. Based on the atomic radii, one nanometer contains 10 Å; hence, one nanometer is likely to contain three to five atoms.

Nanocrystalline materials are extremely hard, strong, and ductile, at high temperatures. They are also resistant to corrosion, wear, and erosion, and are chemically very active.

Nanomaterials, or nanocrystalline materials, are also much more formable when compared to their traditional equivalents available on the market. Nanomaterial research literally exploded in the United States in the mid-1980s.

Production of Nanomaterials

Five popularly known techniques are available to produce nanomaterials. These include:

- Inert gas condensation

- Sol-gel synthesis

- Electrodeposition

- Plasma synthesis

- High-energy ball milling or mechanical alloying

Sol-Gel Synthesis

With the help of this process, nanomaterials can be synthesized to varying degrees of commercially-viable quantities. So far, of all the aforementioned processes, only sol-gel synthesis can:

- Produce large quantities in a commercially viable and cost-effective way

- Create materials (both ceramics and metals) at very low temperatures (around 150 °F–600 °F vis-a-vis 2500 °F–6500 °F for traditional methods)

- Co-synthesize two or more materials at the same time

- Produce virtually any material

- Produce highly homogeneous alloys and composites

- Coat one or more materials onto other materials (three-dimensional objects and ceramic or metal particulates)

- Produce materials with ultra-high purity (99.9999%)

- Precisely regulate the chemical, physical, and mechanical properties of end products

- Accurately control the microstructure of end products

- Customize the composition correctly even during the initial stages of the process, because the synthesis is actually carried out at on an atomic level