For many years, automated SEM-based particle and feature analysis has been utilized in a number of applications such as technical cleanliness analysis and gunshot residue analysis. The combination of chemical and morphological information on a particle by particle basis helps in gaining a better insight into the nature of particulated samples, including the origin of the particles and their contribution in the processes under analysis.

AZtecFeature, an advanced SEM software solution for particle analysis from Oxford Instruments, provides improved user experience, increased speed, and high precision.

This article considers AZtecFeature in the context of geology, engine wear monitoring, and air cleanliness and pollution. It also discusses how major advancements in AZtecFeature together with new developments in EDS detector hardware make it a convincing proposition for practitioners and researchers alike.

Particle Analysis in the SEM

The process of particle analysis is as follows:

- An electron image of a field of view is recorded and particles are detected from the background using grey level thresholds. In certain cases, a single threshold is utilized for all particles, while in others multiple thresholds are used to differentiate different types of particles.

- Chemical and morphological information is recorded from each particle.

- The particles are grouped using the morphological and chemical data by applying “classification schemes”.

The AZtecFeature Approach

Fully integrated with Oxford Instruments’ AZtec® microanalysis suite, AZtecFeature brings a number of advances to particle analysis in the SEM. It leverages the performance and ease of use of Aztec and the accuracy and speed of X-MaxN silicon drift detectors.

AZtecFeature combines the benefits of AZtec’s Tru-Q® quantification large area SDDs and 64 bit processing, and obtains particle data quickly and accurately through a guided workflow for ease of use. Instant feedback is given in real time since particle morphology is determined immediately as grey level thresholds are defined and thus makes optimization quick and simple.

UP to four X-MaxN SDD devices with a detection area of 600mm2 can be utilized to obtain X-rays at high count rates, allowing the highest throughput and short acquisition times during automated large area runs studying countless of particles. The spectra achieved from all the particles are subjected to AZtec’s data processing.

The Tru-Q algorithm rectifies for pulse pile up and background effects and carries out peak overlap deconvolution. This ensures that precisely-quantified information is achieved from each individual particle. These developments are described in the following case studies.

Particulated Geological Sample Live Setup on a Single Field and Acquisition from a Large Area

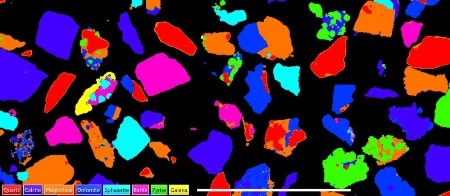

Geological samples are complex particulated samples as each particle may include numerous grains, each of a different mineral phase as shown in Figure 1.

Figure 1. AutoPhaseMap showing complex mineral grains.

For more information on this application example, download the full particle analysis application note.

Download Application Note

Wear Debris – Extracting Particle Data from a Large Area Map

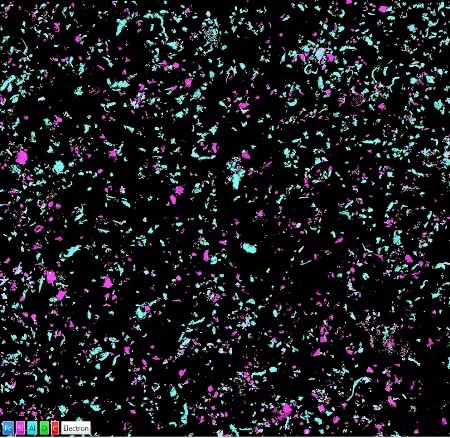

Mapping is commonly utilized for the manual and exploratory analysis of a sample. With the help of AZtecFeature, it is possible to produce a virtual sample by storing and processing large area X-ray maps. In this example, particle data is obtained from a previously acquired mapping dataset on an offline system, and chemical and morphological data for all particles across the sample are collected without the need for additional live acquisition.

Figure 2. Large Area Montaged Map created from 12 Fields from which particle data was extracted.

For more information on engine wear analysis with AZtecFeature, download the full application note.

Download Application Note

Particles on an Air Filter – Low kV Analysis with Multiple X-MaxN SDDs

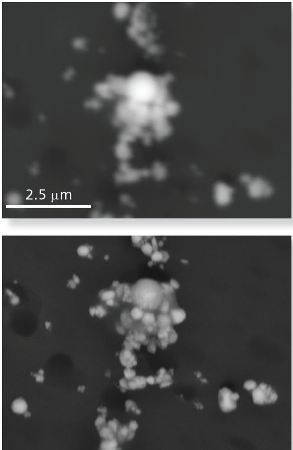

When airborne particles escape into the atmosphere as pollutants, they can prove dangerous for human health. As a result, a better understanding regarding the morphology and chemistry of particles collected on air filters is important.

The particles present in this sample were mostly metallic in composition and sat upon a polycarbonate filter which was susceptible to beam damage. The particles differed in size between 300nm and agglomerations of multiple particles amounting to several µm. For smaller minimum particle size, a lower accelerating voltage had to be utilized so that the interaction volume of the electron beam with the sample was minimized.

Figure 3. Backscattered electron images of small particles on an air filter acquired at 20 kV (top) and 10 kV (bottom). Better image resolution (clearer, less blurry image) is achieved at 10 kV. enabling more accurate measurement of particle morphology.

For more detail on this application example, download the full application note.

Download Application Note

Conclusion

As a flexible particle analysis tool, AZtecFeature makes particle analysis an easy and simple process. By leveraging 64 bit computing power and up to four X-MaxN SDDs, this SEM software solution is able to acquire chemical information and process it quickly, thus making the inspections of large area with thousands of particles easy and efficient.

Additionally, Tru-Q algorithms make sure that data quality is sustained, even at the highest count rates. Classification setup and assisted grey level threshold make these complex steps simple.

Immediate feedback given during these steps allows users to observe the effects of their changes and thus enables them to reach an optimized classification/setup more quickly and easily.

This information has been sourced, reviewed and adapted from materials provided by Oxford Instruments NanoAnalysis.

For more information on this source, please visit Oxford Instruments NanoAnalysis.