The MAX300 series of quadrupole mass spectrometers offered by Process Insights is perfect Process Analytical Technology (PAT) solution for bioprocess reaction monitoring.

The Process Insights MAX300 has the ability to monitor multiple components in multiple streams, fast response, parts per billion (ppb) detection limit and flexible analysis for improved fermentation control. The MAX300-BIO and the MAX-300 BIO LG are depicted in Figure 1.

Figure 1. The MAX-300 BIO LG and the MAX300-BIO

Performance Benefits of the MAX300 Series

The performance benefits of the MAX300 series of quadrupole mass spectrometers are as follows:

Reduced Cycle Time

The Process Insights MAX300 takes roughly 400 milliseconds to analyze a single component, which translates to below 10 seconds to perform one full sample analysis. With this speed of response, users can monitor dozens of bioreactors using a single analyzer.

Improved Yields

Since the bioreaction process is continuously monitored, the operator can fully understand the culture’s health and the process efficiency. The Respiratory Quotient (RO) can be calculated within a standard deviation of 0.007, thanks to the high analysis accuracy of the Process Insights MAX300.

Reduced Waste

Many of the fermentation process issues are indicated by the presence of ppm level components. The process can be quickly adjusted without affecting the batch quality by monitoring these components. The dynamic range of the Process Insights MAX300 is 100% down to 10ppb.

Typical Analysis Information

The incoming air and the off-gas from the fermenter can be analyzed accurately, rapidly, and comprehensively using the Process Insights MAX300. Table 1 shows a typical fermenter exhaust gas composition as well as the expected Relative Standard Deviations, RSD(F), for each component.

Table 1. Typical fermenter analysis method

| Name |

Estimated Concentration (%) |

Sensitivity |

Detection Mass |

RIF |

RSD (F) |

RSD (M) |

| Nitrogen |

70.00 |

1.000 |

28 |

<0.01 |

0.0366 |

— |

| Formaldehyde |

0.10 |

1.000 |

29 |

5.251 |

2.4208 |

— |

| Oxygen |

20.00 |

0.980 |

32 |

< 0.01 |

0.0692 |

— |

| Argon |

0.93 |

1.500 |

40 |

< 0.01 |

0.2592 |

— |

| Carbon Dioxide |

0.05 |

1.860 |

44 |

< 0.01 |

1.004 |

— |

| Water |

0.50 |

0.800 |

18 |

< 0.01 |

0.4841 |

— |

The Respiratory Quotient (RQ) can be calculated from the analysis of oxygen and carbon dioxide in conjunction with the analysis of inerts. It is a key parameter to control bacterial health and growth. The RO calculation can be within a standard deviation of 0.007 due to the expected analysis performance RSD(F), of the Process Insights MAX300. By-products of minor ppm/ppb level concentrations, such as ammonia, acetic acid, methanol, and formaldehyde, are also analyzed for rapid adjustment of the process in order to eliminate unwanted reactions and batch quality issues.

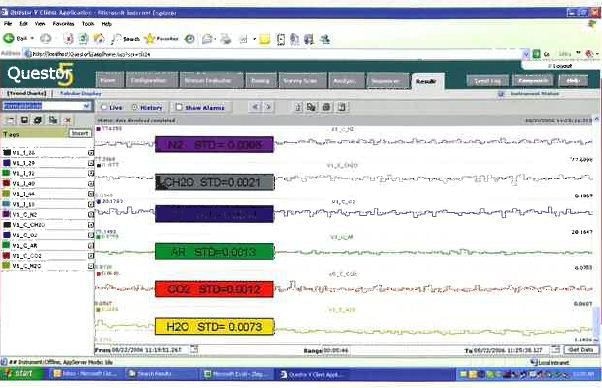

An analysis trend of fermentation head-space data that includes formaldehyde is shown in Figure 2. The data was acquired using a MAX300 equipped with Ouestor 5 software. The standard deviation of the analysis data for each component, as estimated by the trending program, is also shown in the image.

Figure 2. Fermentation data trend with standard deviations (STD)

Application Background

The industry demand for precise and measurable low level analysis has been increasing with the PAT advancement and a focus on process efficiency and improvement. The metabolic changes that favor a fermentation process occurs in a narrow environmental range in most the fermentation processes. The yield and product quality can be optimized by tightly controlling process parameters, including pH, aeration rate (dissolved oxygen), and temperature. This necessitates the use of computerized process control in fermentation processes in order to reduce production costs without affecting product quality.

The use of a fast analyzer such as a mass spectrometer enables short analysis times necessary for optimization of the fermentation process, while maintaining superior quality measurements. The Process Insights MAX300 quadrupole mass spectrometer is a cost-effective option to multiple infrared and oxygen analyzers mounted over each fermenter. Process Insights also supplies a diverse range of inlet solutions, including an 80-port high flow rotary valve called the Process Insights FAST\/alve, to address the sampling requirements of customers.

Key Application Facts

The key application facts of the Process Insights MAX300 series are listed below:

- With a typical analysis cycle of less than 10seconds/stream, the MAX300 can monitor 80 sample points within 15min when coupled to the Process Insights FASTValve

- The MAX300 can attain a continuous dynamic range of 100% down to 10ppb with the Dual Faraday and Electron Multiplier Detector and its Autoranging capabilities

- The Questor 5 web-based user interface from Process Insights can satisfy 21 CFR Part 11 requirements

- A diverse range of industry standard communications, such as Bi-directional MODBUS, Ethernet, OPC, MODBUS RTU or TCP/IP, and analog communication protocols, are supported by the Process Insights MAX300

This information has been sourced, reviewed and adapted from materials provided by Process Insights - Mass Spectrometry.

For more information on this source, please visit Process Insights – Mass Spectrometers.