Induction annealing provides precise and reliable control of metal material properties. It is predominantly used for soft and stress-relief annealing, providing a number of advantages over traditional methods. It allows thermal elimination of impurities in the material during bright annealing.

Process Reliability and Reproducibility are the Focus in Induction Annealing

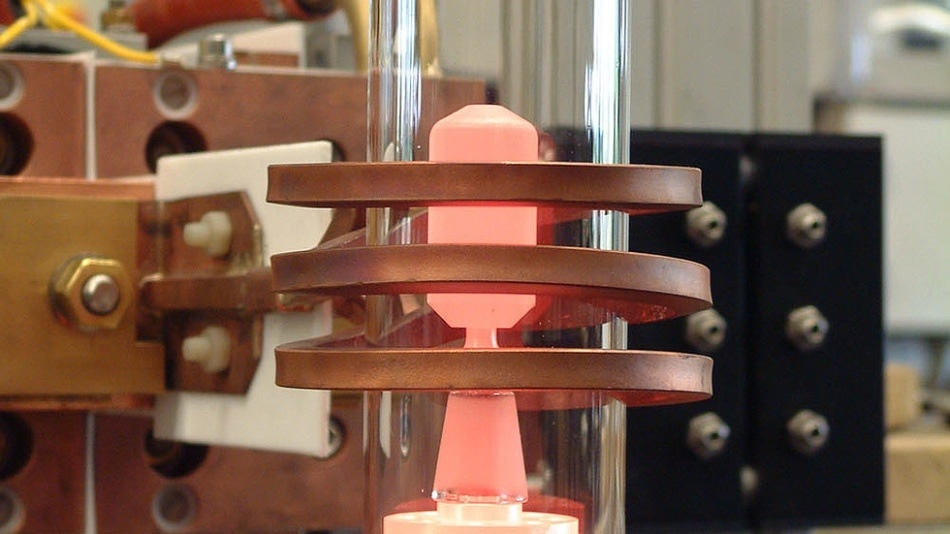

Induction annealing is a sub-area of induction heating. The objective of induction annealing is to specifically influence metals with regard to toughness, hardness, and internal stresses to obtain optimal material properties. The targeted and reproducible heating of workpieces is the key advantage of induction annealing in order to always ensure the same results.

Induction annealing can be controlled very precisely as it produces heat directly in the workpiece using an alternating electromagnetic field. It also has a very high degree of efficiency due to its effective use of energy, which ensures a homogeneous heat distribution and an even depth of penetration in the workpiece.

Unlike induction hardening, cooling is not performed abruptly with water or coolants in induction annealing. Instead, the temperature of the workpiece is gradually reduced. The entire heating process is performed in a very short time without contact.

The entire induction annealing process can be optimally fine-tuned to obtain the desired material properties via the power, frequency, and annealing time, offering excellent options for heat control. This capability not only ensures a high quality heat treatment, but also reproducibility, a critical aspect of mass production.

eldec Generators for Induction Annealing

eldec supplies a wide variety of generators for induction annealing, ranging from pure energy sources (generators) to complete heating systems.

- PICO generators

- eldec ECO LINE – HF generators

- eldec ECO LINE – MF generators

- eldec CUSTOM LINE – DF generators

- eldec CUSTOM LINE – MF/HF/LF generators

- eldec CUSTOM LINE – SDF® generators

Soft Annealing – A Variant of Induction Annealing

Induction annealing is applied when the degree of hardness of a metal needs to be reduced in order to subsequently transfer the workpiece, for example, to a forming process. This process is also known as soft annealing, where the strength of the metal is decreased and the toughness is increased considerably.

As a result, metals treated by soft annealing can be much better deformed. The temperature range for soft annealing may differ significantly based on requirements and the specific application.

Induction Temper – Reduction of Stresses in Workpieces Through Induction Annealing

Stress-relief annealing is another type of induction annealing, where much lower temperatures are used. In this induction annealing process, metal workpieces are heat-treated in order to reduce stresses created during machining or forming, and in the best-case scenario to remove them completely. Workpieces with high internal stresses can also be heat-treated using stress-relief annealing.

Induction Annealing - eldec videos

This information has been sourced, reviewed and adapted from materials provided by Eldec Induction USA, Inc.

For more information on this source, please visit Eldec Induction USA, Inc.