Abrasion testing is a necessity for manufacturers who are interested in producing high-quality products with a long lifespan. With a multitude to different testing methods available, each with their own nuances, it can be difficult to decide which test to use.

AZoM spoke to Alan Jaenecke, from Taber Industries, about the different types of abrasion testing available to manufacturers and why he believes the Taber Test is superior.

Why is it important that wear testing be performed?

The primary reason companies conduct abrasion resistance tests is to ensure they are producing a quality product that is free from defects; consistent in performance; and will endure throughout its life cycle.

The ideal solution would be to analyze a material’s wear resistance in actual use. Unfortunately, this approach often takes many years before useful data becomes available. Additionally, the cost of conducting a field test could be prohibitive and the complexity of identifying and monitoring the influences can be unwieldy. An accelerated laboratory test is appealing because companies can compress the life span of a product into a much shorter duration within a controlled and monitored environment. Plus, it allows materials to be tested in the same manner, and under the same conditions.

For many products, an established test protocol has been developed to ensure test results are comparable. This allows a company to demonstrate they meet a minimum performance standard. Or testing can help a company gain a competitive advantage by showing how it performs compared to the competition. Another advantage of testing is to evaluate the impact of supplier or material changes before they are implemented. In today’s competitive environment, lower cost options may be appealing but have unintended negative consequences on product quality.

While a lab test may not represent the actual conditions materials are exposed to, testing can duplicate many real world conditions allowing you to have higher reproducibility with your evaluations. And following an established methodology helps ensure your results will be both repeatable and reproducible.

Abrasion testing plays an important role in developing consumer products which will undergo wear in their lifetime - from the material used to make trainers to the upholstery on furniture. shutterstock.com | Olaf Speier

What different types of wear testing instruments are available to manufacturers?

There are numerous instruments available that can simulate different types of wear modes. Taber’s solutions are versatile, affordable, easy to operate and allow the user to evaluate:

- Two-body abrasive wear – hard particles are forced against and moved along a solid surface;

- Sliding wear – occurs between two solid bodies and is generated from a reciprocating motion;

- Mar abrasion – permanent deformations that have not ruptured the surface of a coating, but tend to disfigure or change the appearance of its surface;

- Rolling abrasion (or three-body wear) – happens when abrasive particles or debris are allowed to “roll” between the surface and a contacting substance.

Knowing which test method your industry uses is typically the first step to determining which instrument is right for your application.

However in many cases, material advances are outpacing test method development and historic methods may not be applicable. This leaves many manufacturers guessing which instrument they should be using. Taber Industries is often called upon to lend our expertise in these situations to offer our advice and consultation.

Taber’s two most popular options include our Model 5135 Rotary Abraser and Model 5750 Linear Abraser. In addition we offer the Model 155 Grit Feeder Attachment, Model 418 Crockmeter, Model 800 Falling Sand Tester, Model 5900 Reciprocating Abraser, Model 6160 Oscillating Abrasion Tester, Model 5800 Heavy Duty Linear Abraser and Model 5820 Webbing Abrasion Tester.

Optional attachments also allow different configurations of these instruments to perform specialized abrasion tests for such products as flexible packaging, magnetic stripe, wire / cable insulation, decorated plastics, plus many more.

What does TABER testing involve? Why do you consider this abrasion testing method to be superior?

The ”TABER test” was first introduced in the 1930's, and quickly gained popularity because of its ability to provide reliable data in a matter of minutes.

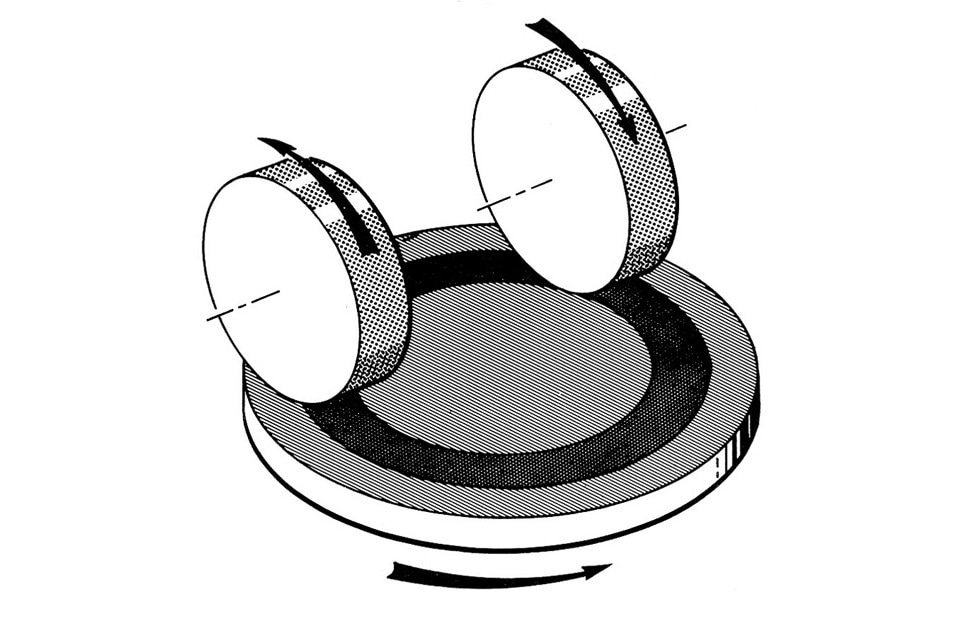

The test is performed using a Taber Rotary Platform Abraser and involves mounting a flat specimen to a turntable platform that rotates on a vertical axis at a fixed speed. Two Taber abrasive wheels, which are applied at a specific pressure, are then lowered onto the specimen surface. As the turntable rotates, characteristic rub-wear action is produced by contact of the test specimen against the sliding rotation of the two abrading wheels while a vacuum system removes loose debris.

The wheels traverse a complete circle on the specimen surface, and the resulting abrasion marks form a pattern of crossed arcs in a circular band that cover an area approximately 30 cm2.

With a selection of different abrading wheels and test loads, the Taber abraser is flexible enough to test wear resistance on a wide variety of materials. Simple to operate, the cost to perform testing is low compared to many other wear testing options, making this a viable option for any manufacturer interested in conducting wear tests.

TABER Test (Abrasion Resistance)

How can environmental effects, such as humidity and temperature, be accounted for when carrying out TABER tests?

Wear is a response resulting from the conditions to which the whole system is exposed. It is important to recognize that resistance to abrasion can be affected by conditions of the tests, including environmental factors.

Because many materials are sensitive to changes in temperature and humidity, tests that are performed under different conditions may introduce variation in the results. Robust test procedures take this into account by requiring the test specimen to be conditioned prior to testing and having the test performed in a temperature and humidity controlled environment.

While it may be desirable to test under different environment conditions, to ensure data is comparable the lab performing the test should ensure they are doing so under the same criteria.

What different types of materials can TABER testing be performed on? Which industries is this relevant to?

Since its introduction, the Taber Abraser has been used for quality & process control, research & development and material evaluation. With the ability to test both flexible and rigid materials, the instrument has been used to test a wide spectrum of materials.

This is evident by the number of test standards and specifications that reference this instrument. Some of the more popular materials include anodized aluminum, automotive carpet, ceramics, coatings, deck coverings, high pressure laminates, digital media, porcelain enamel, floor coverings, glass, leather, luggage, non-wovens, paints & varnishes, paper, plastics, ID and credit cards, safety gloves, synthetic turf, textile fabrics, upholstery, vinyl, plus more.

If a customer is not sure if their material is suited for testing with the Taber Abraser, we encourage them to contact Taber or an authorized distributor to coordinate a free evaluation.

Abrasion testing is of benefit to almost every industry - but is particularly important for testing high wear items such as vinyl. shutterstock.com | Richard Evans

What ASTM or ISO tests can be carried out using TABER testing?

International or company specific standards and specifications help to ensure testing is performed in a uniform and consistent basis. These documents represent written directions of the criteria needed for a specific product, process, test, or procedure. When adhered to, standards allow for test results to be repeatable and reproducible thus enabling you to make useful comparisons of test data.

Currently there are over 150 methods that reference the Taber Rotary Abraser. For a partial listing, please visit our website.

What other factors should be considered when choosing an abrasion tester?

Over the past 100 years, there have been hundreds of wear testing instruments developed. Fortunately, there has been significant work conducted to develop standardized test procedures and many industries specify a preferred tester that is used.

If you are unsure where to start, begin by contacting research industry associations to determine if an accepted abrasion test procedure exists. Other sources of information include organizations that develop test standards, such as ASTM International and ISO.

If a method does not exist or you decide not to follow the industry standard, you need to select a test that models the wear system that you wish to study. Ideally, the test would exactly duplicate a wear situation seen in an intended application, such as a field test. However, given the complexity of wear, an exact simulation is generally neither practical nor possible and some differences will have to be accepted. This is because wear involves two or more bodies, one or more materials, and is dependent on a wide range of influences. Therefore, test development is subject to trial and error and is dependent on the capability of the developer.

The primary elements involved in simulating a wear system include apparatus design, specimen preparation, test protocol, and measurement. The following describe the important features that should be considered: motion; apparatus; materials involved; abradant (wear agent); contact geometry; contact pressure (applied load); sliding speed (sliding velocity); state of lubrication; specimen preparation; and environment.

It is not uncommon for an engineer concerned with reliability and product life to require precise simulation of the wear system. In contrast, a material developer looking to rank the wear resistance of materials may accept a convenient test that does not exactly replicate intended use. In either case, a well thought out wear test can provide valid test data.

Diagram showing the motions of a TABER rotary tester.

How does TABER assist customers in choosing the most appropriate wear tester for their application?

Taber’s application engineers have tremendous knowledge and experience when it comes to wear testing. When we are asked for assistance, we start by asking a series of probing questions to understand the wear problem and materials involved.

Utilizing this information we can help guide the customer to a solution that works for them. This may include recommendations for the appropriate instrument system; assistance with developing a test procedure; understanding evaluation techniques for interpreting results; etc.

For situations that are more challenging, we invite customers to send us their product samples. This allows our in-house test experts to demonstrate how TABER instruments might assist them with quality control, materials research & development, or competitive supplier testing. Customers have used Taber's testing services to:

- Determine if products comply with industry standards

- Anticipate how a product will perform against another similar product

- Enhance competitive advantage

- Assess functionality and appropriateness for intended use

- Reduce risk of product failure & related product warranty costs

- Optimize limited resources

- Carry out materials research and development

- Conduct independent, third-party evaluations

Taber Industries also provides the opportunity to visit our lab for "hands-on" experiences. We invite customers. In addition, Taber can also provide consultation for your abrasion or scratch resistance testing.

Where can our readers find out more about TABER testing?

More information can be found on our website or by contacting your authorized local distributor.

About Alan Jaenecke

Alan Jaenecke has been employed by Taber Industries since the year 2000, and plays a critical role in the company’s Materials Test and Measurement division. Although his main responsibilities include sales and marketing, Alan Jaenecke is also involved with new product development and strategic planning.

Having previously operated Taber’s in-house test facility, he has a wealth of experience conducting wear and durability tests. He has shared his expertise in material testing with other organizations including ASTM, ISO, NEMA, Tappi, SPE, and SAE. Through industry affiliations such as ASTM and SAE, he has written new test methods and coordinated numerous reviews for existing methods.

Alan received his Masters of Business Administration from the State University of New York at Buffalo, where he earned a dual concentration in Marketing Management and Corporate Financial Management.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.