Surface Measurement Systems have continued to be at the forefront of the field of dynamic vapor sorption (DVS) since they first developed the technique over fifty years ago. Recent innovations that they have introduced include instruments that facilitate parallel experiments, an ultrasonic sensor for direct vapor concentration measurements and integrated Raman spectroscopy for the observation of phase changes.

AZoM spoke to Vladimir Martis, Product Manager at Surface Measurement Systems, about the new tools that they are providing DVS scientists and the new breakthroughs their instruments are going to be part of.

How has the technique of DVS advanced since its invention over 25 years ago?

Although gravimetric dynamic vapor sorption (DVS) has been around for over two decades, it continues to develop in order to keep up with new research trends in the advanced characterization of materials.

The latest developments in DVS have been focused on the enhancement of hardware and software components to support real-time data collection, with superior quality, over a broad range of temperatures and partial pressures of water or organic vapors.

We at SMS are proud to use only high quality components (e.g.316 Stainless steel, Viton, Kalrez) in the construction of our gravimetric vapor sorption analyzers. Moisture, gas, organic vapors (or combinations of both) are controlled & measured at very high accuracy, reproducibility and repeatability by sophisticated hardware configurations.

Top of the range Ultra balances are the heart of any gravimetric technique and provide extremely low peak-to-peak noise and long-term baseline stability. In-house state of art DVS control software has been designed not only to automate and real-time visualize data collection but also fulfil the latest requirements introduced by different industries and regulatory bodies (e.g. CFR21 Part 11 for pharma). DVS control software is the final elegant solution to simplify and visualize complex experimental parameters and controls.

SMS has also recently introduced a sub-atmospheric pressure DVS (DVS Vacuum) for microporous materials characterization, in particular zeolites and MOFs. The system was developed to address the need for vapor and gas adsorption/desorption isotherms and isobars over a broad range of temperatures and relative pressures from 0.005 up to 1000 Torr. Pioneering coadsorption measurements using 2 vapors or 1 vapor and 1 gas allows for a deeper understanding of the competitive process of two probe molecules on the same solid surface of a material.

The DVS Resolution (Speed of Sound DVS) was introduced last autumn with great success in performing single and multicomponent sorption experiments at ambient pressures using water or organic solvents. This patent pending ultrasonic measurement technology is the first direct measurement of vapor concentration available anywhere.

We are the first to commercially integrate Raman spectrometry with our DVS analyzers as a turnkey solution to complex experimental problems involving sample form and phase changes. Synchronized and automated DVS-Raman experimental set-up and data collection can be performed simultaneously or sequentially.

Lastly, we introduced the DVS Endeavour (5X) with the ability to collect gravimetric vapor sorption isotherms in parallel mode for simultaneous 5 sample throughput.

DVS can be used to probe the strucutre of MOFs - tailor-made 3D strucutres that form important roles in designer catalysis and high volume gas storage. shutterstock.com | Adam Vilimek

The DVS Resolution and DVS Endeavour (5X) are both designed with parallel DVS experiments in mind. What are the benefits of running simultaneous DVS experiments?

Yes indeed, The DVS Resolution and DVS Endeavour (5X) perform parallel experiments, that is, a change in mass is recorded as a function of time at given partial pressure of solvent. The only difference between the DVS Resolution and Endeavour is number of Ultra-balances in the DVS analyzer.

The DVS Resolution has one Ultra-balance measuring changes in mass of a single sample exposed to different relative humidity or partial pressure of solvent, whereas the DVS Endeavour can weight up to 5 samples simultaneously exposed to identical relative humidity or partial pressure of solvent similar to the DVS Resolution.

Since the DVS Endeavour (5X) can handle 5 samples under identical conditions, an understanding of sample batch-to-batch variations, formulation studies and stability determinations are all possible in a single experiment.

What information can the ultrasonic sensor in your new DVS range be used to determine?

The Ultrasonic sensor (Speed of Sound DVS) is a sophisticated sensor that uses speed of sound measurements at constant temperature to directly measure the vapor concentration exposed to the sample during a sorption experiment.

The Ultrasonic sensor is used not only to measure but also control solvent concentrations delivered to a sample chamber in order to obtain correct mass uptakes of vapor by the sample. This technology is patent pending and will change how organic and moisture sorption isotherms are measured and controlled.

Speed of sound is the only method to directly measure solvent concentrations over a wide range of temperatures and partial pressures.

How will the direct measurement of organic vapor pressure be of use to researchers?

Direct measurement of vapor concentration of organic solvents is important for obtaining accurate organic vapor sorption isotherms over a broad range of temperatures because the number of molecules exposed to the sample is directly related to mass uptake.

It is noteworthy that there is no other sensor on the market that can routinely measure, reliably and repeatedly, vapor concentrations of organics over a broad range of temperatures that does not require long and expensive calibrations. Historically, researchers did not measure and control vapor concentration of organic solvents but relied on vapor pressure tables to produce the estimated concentration of solvents.

Please click here if you would like more information on the instrument used in this article or a quote

Please click here if you would like more information on the instrument used in this article or a quote

Have all of these changes opened up any new applications to DVS?

The recent advancement in our DVS technology has opened new applications in the field of materials research using the enhanced moisture, organic vapor and co-solvent measurement/control and superior balance performance.

Highlights applications are in new drug development; characterization of amorphous content of powders; moisture, solvent or co-solvent induced morphology changes; diffusion and permeability measurements in packaging and polymer materials; complex moisture adsorption/desorption in biological samples; moisture/solvent retention and drying kinetics; fuel cell component moisture characterization; adsorption capacity in microporous materials, zeolites, building materials and MOFs to name a few examples.

DVS plays an important role in the discovery and development of novel drugs. shutterstock.com | Looker_Studio

In what applications is the extremely accurate relative humidity of the DVS Resolution important?

The accurate relative humidity (RH) that is generated in DVS Resolution is important for all vapor sorption applications, particularly where small changes in RH have a large effect on product performance.

These include amorphous content determination, moisture sorption kinetics and moisture induced phase transition in materials. The RH generated in DVS Resolution is independently validated by measuring deliquescent points of saturated salt solutions.

How are samples in the DVS Resolution and DVS Endeavour (5X) prepared for analysis?

The preparation of samples for sorption measurements in DVS Resolution and DVS Endeavour (5X) are very similar. As-received samples can be directly loaded into DVS analyzers after a clean metal or glass pan is tared by the balance software.

The samples are subsequently loaded in a clean pan and placed on the balance assembly. Once the sample chamber is closed, a user defined experimental method is started. If the samples require elevated temperature or dry vapor degassing, a 300 ºC preheater and True Zero Rh are also available. This sample preparation can be included in the experimental method.

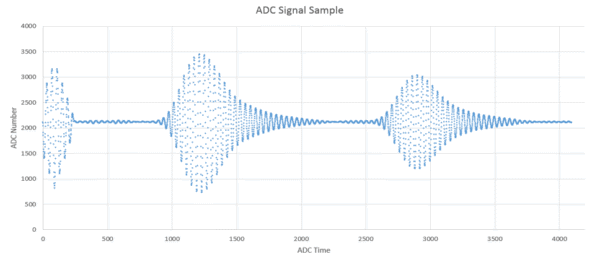

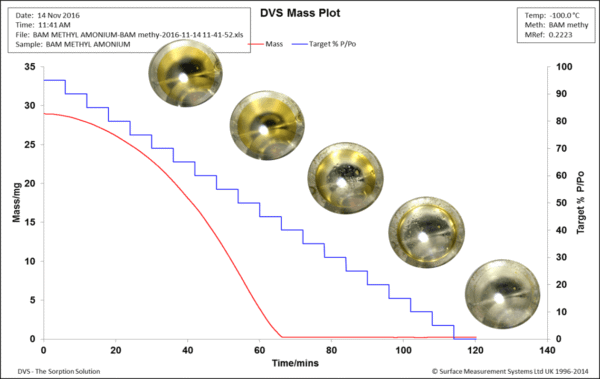

DVS Resolution Drying Kinetics with Microscopy Photograph overlay

How can Raman spectroscopy be integrated with the new instruments?

A Raman spectrometer can be added to the new DVS instruments using the advanced Raman probe holder fitted to the sample chamber. The DVS Raman holder is an essential part of an integrated DVS-Raman system and serves to maintain the optimal working distance between the Raman probe and sample.

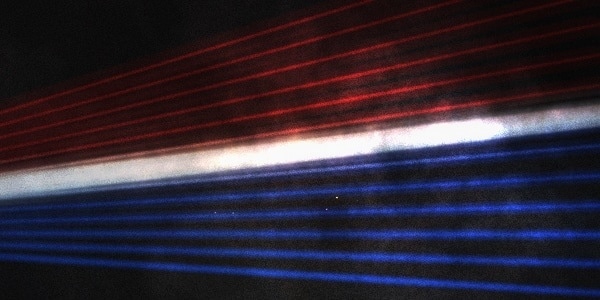

This allows the Raman laser to be directly seen by the sample. The Raman spectrometer is controlled via DVS control software which synchronizes mass and Raman data collection either simultaneously or sequentially. A 200 x light microscope is also available for simultaneous DVS-Raman Spectroscopy-Microscopy experiments. The microscope is also valuable in aligning the sample with the laser path.

Integrating DVS with Raman spectroscopy allows the phase changes that occur during sorption to be observed and analysed.

What additional information does Raman spectroscopy bring to DVS experiments? How do the two techniques complement one another?

DVS measures the physical interaction of the vapor(s) with a solid surface and defines the method isotherm depicting the amount of vapor(s) adsorbed as a function of vapor concentration.

Raman spectroscopy looks at the structural and/or chemical changes the sample undergoes during interactions with the vapor(s) of interest. These interactions may result in formation of different chemical species, forms or phases and are not always visible or definable by the mass change.

The new range of DVS systems from Surface Measurement Systems

Where can our readers find out more about DVS, and the DVS systems provided by Surface Measurement Systems

AZo readers can find more information about DVS products on Surface Measurement Systems website, conferences or scientific posters presented at local or international meetings. DVS data is also published in peer reviewed scientific journals.

About Vladimir Martis

Vladimir Martis is the DVS product manager and vacuum products specialists for Surface Measurement Systems, Ltd located at SMS worldwide headquarters in London, UK. He received his Master’s degree in Materials Engineering from Trencin University of Alexander Dubcek, Slovakia in 2004. He received his engineering doctorate degree (EngD) in Molecular Modeling and Materials Simulation from Chemistry department, University College London in 2012. The thesis title: “Synchrotron radiation studies of multicomponent metal oxides.”

Since joining SMS in 2013, he has continued working on the development of advanced in-situ experimental surface science techniques using molecules as probes instead of X-rays for studying catalysts, zeolites, MOFs, polymers, freeze and spray dried materials, composites and glasses under relevant industrial conditions. Dr Martis has authored several papers in peer-reviewed journals and presented at several international conferences.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.