Too often, designers unfamiliar with ceramic engineering opt to directly replace a metal component, for example, with a like-for-like ceramic part. However, this is usually not the best solution and can unnecessarily increase manufacturing costs and result in the component not working as intended. This guide is aimed at engineers and designers wishing to incorporate advanced technical ceramics, such as silicon nitride, zirconia, alumina, and silicon carbide into existing and novel systems.

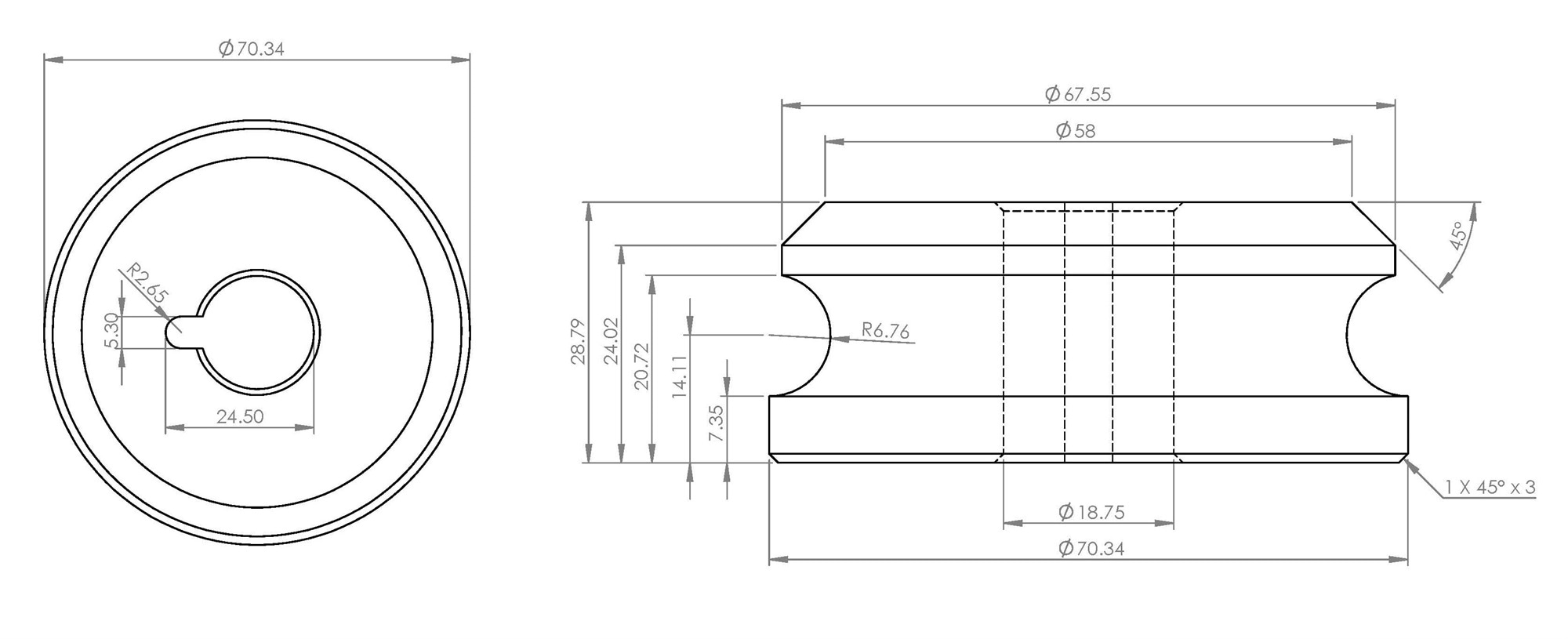

Image Credits: International Syalons (Newcastle) Ltd.

This guide will firstly compare the general physical properties of advanced ceramics to metals, polymers and refractories, in order to highlight the major differences that exist between the different materials groups. Following this, a series of design tips will emphasize the major points to consider when designing and using ceramic components. By following these suggestions where possible, the ceramic part will be simpler and cheaper to make, saving time and money, while still delivering a part 'fit for purpose'.

Materials Comparison

The table below compares some general physical properties of advanced ceramics with metals, polymers and refractories. These three common material types are often replaced by ceramics. The values of ‘low’, ‘medium’ and ‘high’ are not absolute and only indicate a general tendency for a material group for a particular physical property as there is a vast range of materials in each group.

Table 1. Comparison of properties of ceramics, metals, polymers and refractories.

|

Property

|

Ceramic

|

Metal

|

Polymer

|

Refractory

|

|

Tensile Strength

|

Medium

|

Medium/High

|

Medium

|

Low

|

|

High Temperature Strength

|

High

|

Medium

|

Low

|

Medium

|

|

Elastic Modulus

|

High

|

Medium

|

Low

|

Medium

|

|

Compressive Strength

|

High

|

Medium

|

Low

|

Medium

|

|

Toughness

|

Low

|

High

|

Medium

|

Low

|

|

Ductility

|

Low

|

High

|

High

|

Low

|

|

Hardness

|

High

|

Medium

|

Low

|

Medium

|

|

Density

|

Low/Medium

|

Medium/High

|

Low

|

Low/Medium

|

|

Wear Resistance

|

High

|

Medium

|

Low

|

Medium

|

|

Thermal Conductivity

|

Medium

|

High

|

Low

|

Medium

|

|

Thermal Expansion Coefficient

|

Low

|

Low/Medium

|

High

|

Low

|

|

Thermal Shock Resistance

|

Low/Medium

|

High

|

High

|

Low/Medium

|

|

Corrosion Resistance

|

High

|

Low/Medium

|

Low/Medium

|

Medium/High

|

Properties of Advanced Ceramics

The important points to note from this table are that advanced ceramics, although strong and hard, are brittle and lack toughness, particularly in comparison to metals. They are relatively poor under tensile stresses, although excellent under compressive stresses. Due to their complete lack of ductility, ceramics fail suddenly and catastrophically on reaching the critical tensile stress in the region of inhomogeneities in the microstructure. High stresses can occur in the region of sharp edges, corners and holes, for example. On the other hand, advanced ceramics can withstand very high compression loading.

This has the effect of closing up the critical flaws in the microstructure. This property should be utilized in design whenever possible. With these points in mind, the following design tips should be followed where possible. In addition to increasing the component’s chance of achieving the performance required, following these tips will also save time and money during manufacture.

-

Tolerance dimensions as loosely as possible. If a component can be toleranced at ± 1-3% for example, the part can usually be produced ‘as-sintered’. This then eliminates the need to diamond grind the component, which is one of the most costly stages of manufacture.

-

Limit component thickness. The strength of ceramic is limited by the size of its largest flaw. The thicker the component the greater the probability of there being a large flaw. Also, remember that advanced ceramics, such as Syalons and Zircalon, are much stronger than refractories, so in a situation where the ceramic is to replace a thick refractory, a much thinner ceramic part will still do an excellent job.

-

Avoid features that cause stress concentrations, such as sharp edges and corners, sudden changes in cross-sectional area, and small contact points. Sharp edges and corners should be relieved by chamfers, radii, or undercuts. If possible use tapers to gradually change the cross-sectional area. Provide large contact areas to spread the load.

-

Keep the component form as simple as possible. Remember, ceramic components are fabricated by first forming a low density 'green' compact, which is subsequently sintered to full density. This results in shrinkages of up to 30%, which for complicated shapes makes tight dimensional control difficult. (See also point 1 above). In some cases, it may be advantageous to change the form of a non-ceramic part of the design in order to simplify the ceramic component. Alternatively, consider using a modular design, that is, split the component into several smaller, simpler pieces.

-

Keep section or wall thickness as uniform as possible. Large changes in component thickness are another cause of stress concentrations. This can be the case when holes are located off-center, for example. Also, a thin section will densify quicker than a thick section and so warpage or grain growth could occur while the thicker section is still densifying. Grain growth can result in a reduction in strength and should where possible be avoided.

-

Avoid unnecessary diamond grinding. Grinding can cause very high-stress concentrations, which as mentioned above, can cause flaws. However, by optimizing the grinding parameters or by polishing or lapping, this problem can be minimized.

-

Consider a modular design by incorporating a joining technique such as shrink fitting, using adhesives, or screw threads. Shrink fitting works well for example, in assembling a Syalon 101 extrusion die in a steel case. The greater thermal contraction of the steel on cooling, places the sialon die in compression, which as mentioned above, is the preferred environment for ceramics. Adhesives, with excellent properties up to 1600°C are also an option for joining ceramics, such as Syalon and Zircalon. These ceramics can also be mechanically fastened by using a screw thread (both internal and external), for example.

Hopefully, these design tips have provided some points to consider when attempting to incorporate advanced technical ceramics in your design. Should you need more information, please contact one of our technical or engineering staff or see our materials section for more information on the ceramics we manufacture.

.jpg)

This information has been sourced, reviewed and adapted from materials provided by International Syalons.

For more information on this source, please visit International Syalons.