Jun 15 2009

Background

Goodfellow Ceramic & Glass Division are an award-winning company who supply specialist glass and ceramics for scientific and industrial use.

Goodfellow Ceramic & Glass Division aim is to understand your application and then supply the most appropriate materials or components to meet your needs.

Our technical staff are qualified in glass technology and materials science and can, therefore, provide impartial advice and full technical support for your projects.

Macor -Machinable Glass Ceramic

MACOR gives you the performance of a technical ceramic with the versatility of a high performance plastic. MACOR glass ceramic is an outstanding engineering material and is machinable with ordinary metalworking tools.

- It is an excellent electrical insulator

- It has a high maximum use temperature (800°C continuous, 1000°C peak)

- It has a low thermal conductivity and is a useful high temperature insulator

- It is strong and rigid; unlike plastics it does not creep

Producing Unique Components with Macor

When you make unique components from MACOR you can:

- Use MACOR and forget about mould costs, firing shrinkage and diamond machining for high tolerance work

- Use MACOR for your products or use it in your production process

- Use MACOR for one component or for many

MACOR is an invaluable material to have ‘on the shelf’. It is often quicker and cheaper to make a special part rather than try to find that special item somewhere else. If you do not have your own machining facilities, or your workshop is fully occupied, send your drawing to Goodfellow Ceramic & Glass Division who can quote for your finished requirements as well as advise on your application and design.

Applications of MACOR

MACOR's unique properties find many varied applications:

- Electronics/semiconductor industry

- Precision coil formers, high voltage insulators

- Laser industry

- Spacers, reflectors and cavities in laser assemblies

- High vacuum industry

- Thermal breaks, coil supports and vacuum feed throughs

- Aerospace/space industry

- Space Shuttle door and window retaining rings, satellite electrical supports

- Nuclear industry

- Fixtures and reference blocks in power generation units

Composition of MACOR

MACOR machinable glass ceramic is a white, odourless, porcelain-like (in appearance) material composed of approximately 55% fluorphlogopite mica in a borosilicate glass matrix. It has no known toxic effects ; however, the dust created when machining can be an irritant. Any irritation can be avoided by good housekeeping and appropriate machining techniques. The material contains the following compounds:

Table 1. Composition of MACOR machinable glass ceramic.

| Component |

%

|

| Silicon (SiO2) |

46

|

| Magnesium (MgO) |

17

|

| Aluminium (Al2O3) |

16

|

| Potassium (K2O) |

10

|

| Boron (B2O3) |

7

|

| Fluorine (F) |

4

|

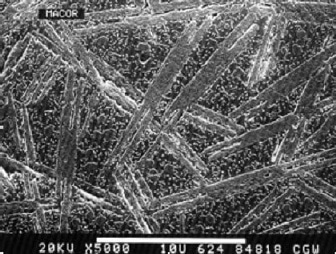

Figure 1. Randomly oriented Mica flakes in the microstructure of MACOR are the key to its machinability. (5000x magnification)

Machining of MACOR

MACOR can be machined to make precision components but its machining characteristics are different to metals and plastics. MACOR consists of interlocking plate-like mica crystals in a glassy matrix. It is these crystals which stop microscopic fractures at the tool tip from spreading through the material, thus making it machinable in a controlled way. During machining the tool pulverizes and tears the MACOR surface producing a fine powder of crystals and glass.

The crystals are so small that, when machined, MACOR has a good surface finish. When machining is complete, the component is cleaned ready for use, no further treatment (e.g. firing) is required.

Setting Up

MACOR machinable glass ceramic is not resilient so, when small or delicate pieces are being machined, make sure that the load is uniformly distributed. Use soft jaws if possible.

It is well worthwhile taking some time to learn how the material behaves during machining. Try some simple tasks such as drilling, turning and milling and you will see how the material machines. This information gives a basis for good machining practice, but do not be afraid to experiment with tools and speeds to obtain the optimum machining performance from your equipment.

MACOR can be machined with high speed steel tools but the use of tungsten carbide tools is highly recommended (ceramic tipped tools are not advised). If the tool squeaks, if the MACOR surface turns greyish through tool wear or if too much force is needed – then stop and sharpen the tool.

As a general rule, machine at lower speeds (keeping the work piece cool) and take smaller depths of cut until you become more confident in machining the material. It is normally the requirement to maintain a surface finish which controls machining speeds. Remember, you are machining a brittle material so always avoid physical shock.

Using Coolant

Although MACOR is a high temperature material, the best machining results are obtained when both the material and tool are kept cool. Water soluble cutting fluids will improve the cutting action, trap and wash away the debris produced during machining and protect machine tools. If the fluid is to be recirculated, the use of a settling tank is recommended. The powder generated during machining is somewhat abrasive and so attention must be given to cleanliness and machine maintenance.

Sawing

Use a carbide grit blade with a 30 m/min band speed, or a diamond or silicon carbide cut-off wheel.

Turning

Using carbide tipped tools, suggested turning speeds are around 600 rpm for ø 5mm-10mm rod, reducing to around 400 rpm for ø 25mm rod. Feed rates are 20-30 mm/minute with a depth of cut of 2-4mm for roughing and less than 1mm for finishing.

Side and back rake angle, end and side relief angles should be around 5°. The recommended side cutting edge angle is 15°-45° and the nose radius should be larger than 0.8mm.

Thread cutting can also be done at low spindle speeds, a typical cutting depth is 0.025-0.040mm per pass.

Milling

Typical head speeds are 1000–1500 rpm with a chip load of 0.05mm per tooth. Depths of cut are as for turning. Climb milling prevents material being pulled off the edge of the MACOR.

Drilling

For holes up to about ø 5mm a spindle speed of 1000–1500 rpm and a feed rate of 20-30 mm/min. has been found to be effective. Relieve the drill flutes constantly, especially for small diameter holes. Check the sharpness of the drill every 25–50 holes. A slow feed is recommended at the start and finish of each hole. To prevent breakout, use a backing plate or chamfer the hole entrance and exit before drilling through thickness. It is possible to ultrasonically drill MACOR.

Tapping

Make the clearance hole one size larger than that recommended for metal (typically 0.1-0.2mm larger). Chamfer both ends of the hole to prevent chipping. A 4 flute tap is preferable to a 2 flute tap. Run the tap slowly in the same direction (turning the tap back and forth can cause chipping) and flush with water or coolant to remove dust. Wire thread inserts can be used with MACOR.

Grinding and Polishing

Diamond grinding wheels give the best results although silicon carbide and alumina wheels can be used. Always use water cooling. Start polishing with a 400 grit silicon carbide, prior to using alumina or cerium oxide powders for the final finish.

Properties of MACOR Machinable Glass Ceramic

Mechanical Properties

Table 2. Mechanical properties of MACOR machinable glass ceramic.

| Property |

Value

|

| Density |

2.52g/cm3

|

| Porosity |

0%

|

| Modulus of Elasticity (25°C) |

66.9GPa

|

| Shear Modulus (25°C) |

25.5GPa

|

| Modulus of Rupture (25°C) |

94MPa

|

| Compressive Strength |

345MPa

|

| Poisson's Ratio |

0.29

|

| Fracture Toughness |

1.53MPa.m1/2

|

Thermal Properties

Table 3. Thermal properties of MACOR machinable glass ceramic.

| Property |

Value

|

| Co-Efficient of Expansion |

-200 to 25°C: 7.4x10-6 /°C

25 to 300°C: 9.3x10-6 /°C

25 to 800°C: 12.6x10-6 /°C

|

| Specific Heat (25°C) |

0.79 kJ/kg.°C

|

| Thermal Conductivity (25°C) |

1.46 W/m.K

|

| Thermal Diffusivity (25°C) |

7.3x10-7 m2/s

|

| Continuous Operating Temperature |

800°C

|

| Maximum No Load Temperature |

1000°C

|

Electrical Properties

Table 4. Electrical properties of MACOR machinable glass ceramic.

| Property |

Value

|

| Dielectric Constant (25°C) |

@1kHz: 6.03

@8.5GHz: 5.67

|

| Loss Tangent (25°C) |

@1kHz: 4.7x10-3

@8.5GHz:7.1x10-3

|

|

Dielectric Strength

(AC avg 0.3mm thick sample @ 25°C)

(DC avg 0.3mm thick sample @ 25°C)

|

9.4kV/mm

62.4kV/mm

|

| DC Volume Resistivity |

>1016Ω.cm

|

Chemical Properties

Table 5. Chemical properties of MACOR machinable glass ceramic.

| Solution |

Tests

|

Results

|

| |

pH

|

Time

(Hours)

|

Temp

(25°C)

|

Wt loss (mg/cm2)

Gravimetric

|

| 5%HCl |

0.1

|

24

|

95

|

-100

|

| 0.002 N HNO3 |

2.8

|

24

|

96

|

~0.6

|

| 0.1 N NaHCO3 |

8.4

|

24

|

95

|

-0.3

|

| 0.02 N Na2CO3 |

10.9

|

6

|

95

|

~0.1

|

| 5% NaOH |

13.2

|

6

|

95

|

-10

|

| Resistance to Water over Time |

| H2O |

7.6

|

24*

|

95

|

0.01

|

|

|

72*

|

95

|

0.07

|

|

|

168*

|

95

|

9.4

|

|

|

72†

|

95

|

0.06

|

|

|

144†

|

95

|

0.11

|

* Water not freshened daily

† Water freshened daily

The above general characteristics of MACOR were derived from laboratory tests performed by Corning, Inc. on sample quantities. The actual characteristics of production batches may vary.

Source: Goodfellow Ceramic & Glass Division

For more information on this source, please visit Goodfellow Ceramic & Glass Division