Sponsored by XradiaApr 22 2013

Solid foams are structures containing gaseous voids enclosed by a denser solid matrix such as metals, alloys or polymers. Their high strength-to-weight ratios and ability to stay intact under high degrees of deformation make them suitable for a myriad of applications, including load bearing components, packaging material, acoustic and thermal insulators, and shock and impact absorbers in vehicles.

Challenges of 3D Morphology Characterization of Solid Foams

The three-dimensional properties of the foam play a key role in their performance and application. These properties, in turn, closely rely on the foam’s composition, material properties and morphology. Since solid foams have intricate and irregular structures, it is difficult to perform 3D characterization for these materials, especially at sub-micron resolution.

Characterization of the 3D morphology of solid foams is highly significant. Nevertheless, the shortcomings of traditional techniques have limited its scope. High resolution methods such as physical sectioning combined with electron or optical microscopy are time-intensive and destructive. Moreover, they can cause physical artifacts and cannot perform time-dependent microstructural evolution analyses as they are destructive. On the other hand, low resolution is the limitation for non-destructive traditional micro-computed tomography (micro-CT).

Solutions from Xradia

During the past decade, traditional X-ray micro-CT has been widely used for non-invasive and non-destructive characterization of foams. With medium resolution on the micron scale, these systems have enabled quantitative characterization of morphology and pore structure, which provide insight into the physical and mechanical properties of foams. Nonetheless, micro-CTs find it difficult to image some low-Z materials, such as polymer foams, with good contrast. Moreover, they cannot resolve submicron foam pores.

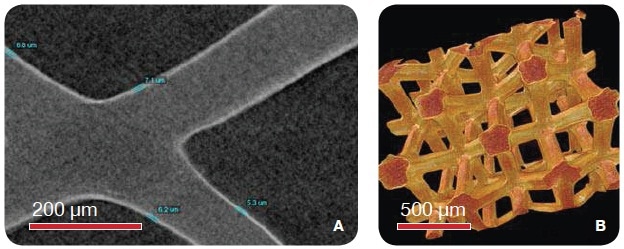

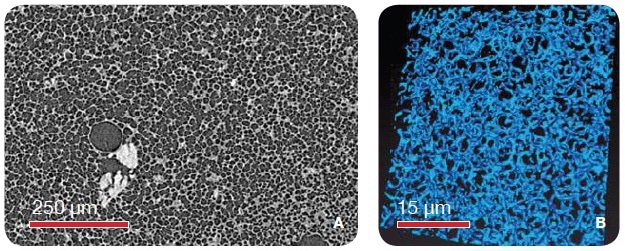

The VersaXRM and UltraXRM families of 3D X-ray microscopes from Xradia enable submicron spatial resolution imaging of foam structures. The VersaXRM achieves a spatial resolution of down to 0.7 µm, while the UltraXRM achieves a spatial resolution of <50 nm. The unique X-ray optics architectures developed by Xradia maintain such high resolutions over large working distances and do not allow their degradation as a linear function of sample size. This provides new functionalities such as high-resolution imaging for in situ analyses, for instance, foam compression in an in situ rig. Furthermore, Xradia's optimized scintillator detectors on the microscopes enable high contrast imaging of low-Z foams. The capabilities of the VersaXRM and UltraXRM are demonstrated in Figures 1 and 2.

Figure 1. Ni-plated foam imaged using the MicroXCT (VersaXRM family) with 1.6 µm voxel size. (A) The 2D virtual slice shows the thin Ni plating of about 7 µm thickness. (B) The 3D rendering of the two phases of the foam. (Images courtesy Los Alamos National Laboratory)

Figure 2. Solid Foams (A) Microcellular foam imaged using the MicroXCT (VersaXRM family) and 1 µm voxel size resolutions. (B) Polystyrene foam imaged using the UltraXRM-L200 using 65 nm isotropic voxels. (Images courtesy Los Alamos National Laboratory)

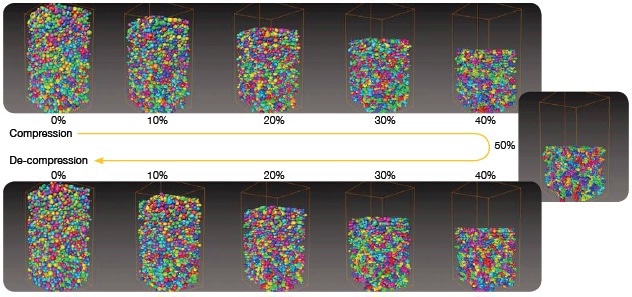

Cellular materials are employed in many different load bearing and structural applications, wherein they are routinely subjected to different levels of stress or loading. Mechanical testing is essential element of full characterization for these kinds of foams. The non-destructive characteristic of 3D XRM provides unique characterization capability, which enables 4D (time-dependent) analyses in different environments utilizing in situ chambers and devices. It not only provides a unique method to explore the microstructural changes of the foam, but also offers a technique to validate computational modeling.

The results of an in situ loading-unloading experiment performed on a MicroXCT are shown in Figure 3. From the results, the impact of compression on the structure of the foam was revealed. The foam cells were not able to retain 100% elastic properties as they were permanently affected by compression. Each image shown in Figure 3 is a full 3D depiction of the foam at different compressive states. The colored balls, as shown in Figure 3, are the individual segmented cells in the material.

Figure 3. A MicroXCT series captured 3D images of an in situ loading-unloading experiment. The results showed that the compression curve was not retraced during the decompression, showing that the foam cells did not exhibit 100% elastic properties. (Images courtesy Los Alamos National Laboratory)

Conclusion

In this way, characterization of open-cell and closed-cell foams and 4D (time-dependent) in situ compression analysis of foams can be successfully performed with the high-resolution, non-destructive imaging provided by the Xradia VersaXRM and UltraXRM X-ray microscopes.

This information has been sourced, reviewed and adapted from materials provided by Xradia.

For more information on this source, please visit Xradia.