Sponsored by XradiaApr 22 2013

Fiber-reinforced composite materials of a polymer matrix that have been reinforced with carbon, fiberglass or synthetic fibers are used increasingly in the construction of materials for the aerospace, automotive, marine, and construction industries because of their strength, high performance, and light weight. The internal structure of fiber-reinforced composite material greatly affects the strength and function of constructed materials, and it is crucial for engineers to be able to visualize and measure key features. X-ray microscopy (XRM) can provide quantitative, high resolution, three-dimensional microstructural analysis of considerably large samples in situ to understand reliability and failure mechanisms.

Furthermore, the non-destructive nature of X-rays helps in imaging a sample before and after the application of tension or shear to observe resulting changes in the microstructure of these materials.

This article covers the application of the Xradia VersaXRM for detailed nondestructive imaging of fiber composite samples. VersaXRM instruments offer submicron spatial resolution, high contrast and the unique ability to maintain high resolution at large working distances for detailed imaging of large intact samples. The analysis of the resulting 3D datasets was accomplished with Avizo Fire software as shown in Figures 1 and 2.

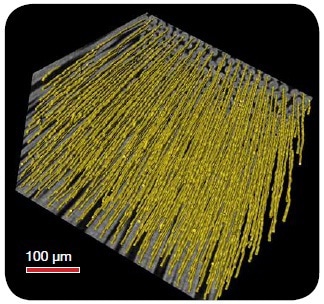

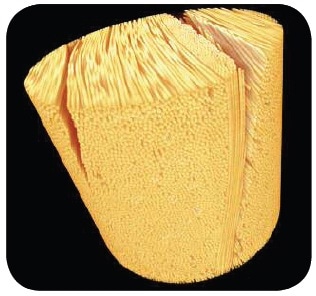

Figure 1. Carbon fiber composite, courtesy of ICMCB

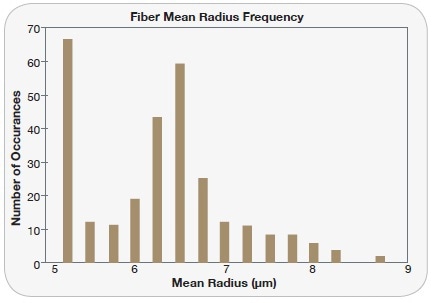

Figure 2. Quantification of fiber mean radius

Methodology and Results

In this study two fiber composite materials are studied:

- The first sample is made of carbon fibers in epoxy resin

- The second sample is a commercial product known as Twintex, a composite of polypropylene and E-glass fibers in a polymer matrix.

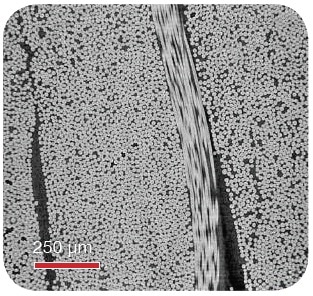

The carbon fiber sample shown in Figures 3 and 4 was a 10 x 15 cm x 2 mm sample imaged at 1.46 µm voxel. The novel use of scintillators optimized by objective make the detectors of the VersaXRM 3D X-ray microscope uniquely suited to imaging these low Z materials with sufficient contrast. For this scan, the system was operated at 60 kV and made use of high absorption contrast imaging to visualize voids in the epoxy and clearly differentiate carbon fibers from the surrounding matrix for segmentation analysis.

Figure 3. Virtual orthogonal slice of the composite, showing carbon fiber and epoxy

Figure 4. 3D rendering image of the composite, showing carbon fiber. Courtesy of ICMCB

X-ray microscopy (XRM) offers quantitative, three-dimensional structural analysis of relatively large samples for understanding reliability and failure mechanisms and helps image the sample before and after the application of other conditions to observe micro-structural changes.

The Twintex sample, a four-layer thermoplastic composite measuring 85 x 17 x 2 mm, was imaged at 1 µm voxel at 40 kV. The material is a continuous fiber composite made of a polymer matrix and E-glass with polypropylene fiber reinforcements as shown in Figures 5 and 6. Imaging and subsequent analysis provided information including void content, fiber orientation, and the interface between composite layers.

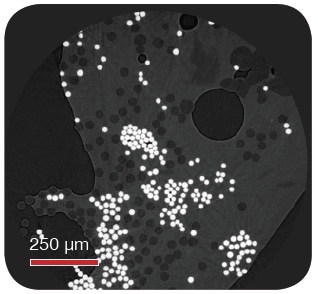

Figure 5. Virtual cross-section of Twintex composite, showing polypropylene (dark) fibers and E-glass (bright) fibers. Voids in the composite can clearly be seen as dark spherical shapes. Courtesy of Professor Milani, University of British Columbia

Figure 6. Segmented 3D image of the composite, showing green fibers (E-glass), orange fibers (polypropylene), and white spheres (voids). The analysis indicated that E-glass fibers are clustered together and randomly distributed, which may influence the strength of the material, and that there are many unconsolidated polypropylene fibers left in the sample. Courtesy of Professor Milani, University of British Columbia

Conclusion

This case study shows that the VersaXRM can be effectively used for 3D structural analysis of fiber reinforced composite materials, which is often limited by traditional microscopic techniques. Due to its non-destructive nature and unique architectural design, the VersaXRM can acquire high contrast and high resolution images of polymer fiber composites, preserving the sample so that it may then be studied with additional methods such as dynamic mechanical analysis and mechanical shear tests.

This information has been sourced, reviewed and adapted from materials provided by Xradia.

For more information on this source, please visit Xradia.