Oil analysis not only provides early indications of equipment wear, but also identifies the root causes of corrosion. On-site oil analysis eliminates the wait time associated with delivering samples off-site and enables instant decision making.

By combining four simple tests, the MiniLab 153 provides comprehensive on-site oil analysis, delivering instant actionable results, and saving time and costs.

Key features of this system are as follows:

- One product, delivering lab-quality analysis beyond the laboratory

- Simplified data handling and report interpretation via OilView and Trivector reporting

- Simplified workflow for non-expert users; no chemist required

Highlights

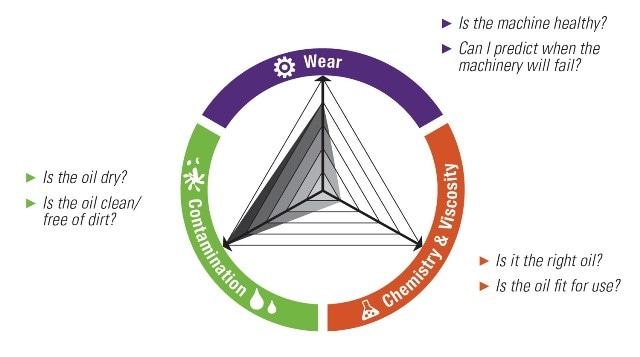

Trivector™ – Oil and Machine Health Simplified

The TriVector™ is a simple representation of the integrity of the lubrication system and the machine health. It indicates the degree of health in each vector. The Trivector condition can be understood by measuring the key physical and chemical parameters of the oil.

The following questions can be answered:

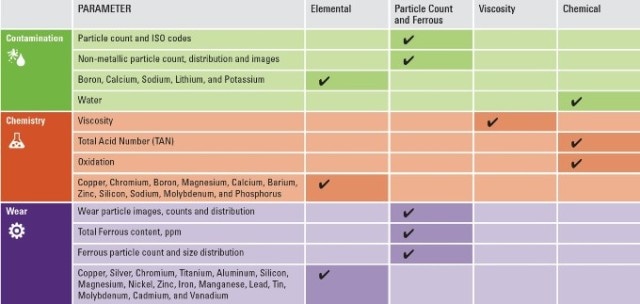

The MiniLab 153 Combines Four Simple Tests that Take Less than 20 Minutes to Complete

(Click on any four tests below to watch how-to videos)

- Particle Count and Ferrous

- Viscosity

- Elemental Analysis

- Chemical Analysis

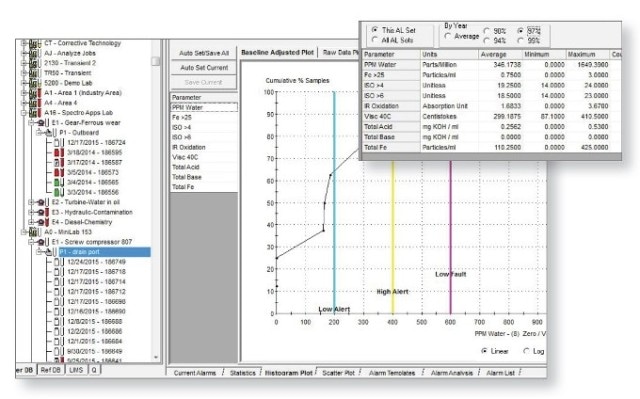

OilView™ LIMS Asset Management Software

The Minilab 153 is operated using the AMS OilView LIMS software, which features an Asset Management database and a reference oil database that can be expanded by end users.

The software provides several standard and configurable report formats with alarm limit templates and analytics, and automatic email distribution of reports.

Color-coded Trivector reports provide a clear picture of machinery health by identifying parameters that are beyond normal limits.

Target Industries

The MiniLab 153 is suitable for the following industries:

- Industrial Manufacturing

- Power Generation

- Metals Processing

- Pulp and Paper

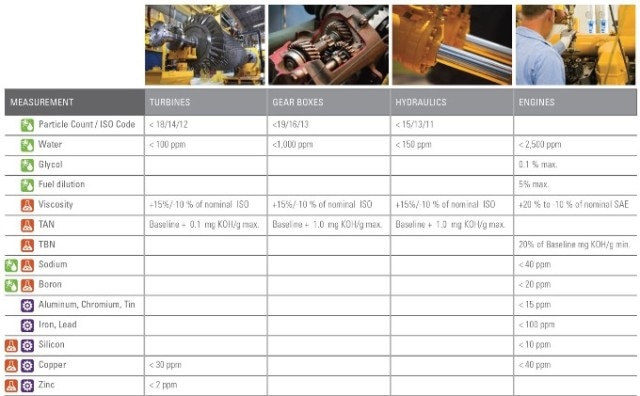

Typical Limits for Machinery

The most common oil analysis tests and typical alarm limits for various components are listed in the following table. Alarm limits are established by component manufacturers for their equipment for specified parameters.