Jun 28 2009

Swiss manufacturer Buss AG, Pratteln, has set yet another benchmark with its 4-flight quantec Kneader. Among other advances, rigid PVC compounding with up to 100 phr fillers is now possible on this machine. The key engineering and technological innovations are:

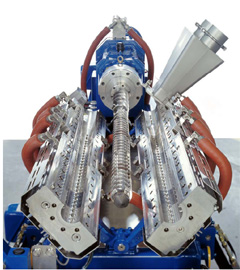

BUSS quantec® 80EV Kneader with 15 L/D process zone for compounding

high-fill rigid PVC. Photo: Buss AG, Pratteln (Switzerland)

BUSS quantec® 80EV Kneader with 15 L/D process zone for compounding

high-fill rigid PVC. Photo: Buss AG, Pratteln (Switzerland)

- Process zone extension to 15 L/D (screw length/diameter)

- Addition of a downstream vertical Inlet Screw (IS) for feeding fillers directly into the gelled PVC melt.

Both these intake zones have a larger housing and screw diameter (Expanded Volume Intake, EVI), enabling the biggest possible fillers take-up volume in the process zone.

The compounding process in this high-performance BUSS Kneader remains largely unchanged. Dryblend is gravity-fed to the intake together with all additives and some of the fillers required. The remaining fillers are likewise gravity-fed through the vertical Inlet Screw directly to the melt. After mixing, the PVC compound passes as usual through a discharge screw that builds up the necessary pressure for pelletizing.

Best proven in practice is a fillers content of 35 phr (by volume) in the dryblend, and 65 phr fed separately. Trials on the quantec 50EV test facility have shown that with 100 phr chalk (CaCO3) filling, throughputs as high as 390 kg/h are possible with consistently excellent compound quality. These quality and throughput results have been confirmed in practice with quantec Kneader sizes up to 110EV. For scale-up to this size, a throughput factor of 1:10 has to be applied.

PVC profile extrusion: high surface quality at low cost High-fill rigid PVC compounds produced on the BUSS quantec Kneader with lowcost fillers, mainly chalk, are ideal for profile extrusion. They enable the low-cost production of decorative profiles for e.g. windowsills and parapets, ceiling and wall coverings - simply by changing the profile extruder feed from dryblend to pellets. These products have an attractive satin gloss surface quality despite their high chalk content.

BUSS CEO Beat Sturzenegger points out how customers benefit from these advances: "Our quantec high-performance Kneader - already a reference for PVC compounding - can now produce extremely high-fill rigid PVC compounds in a single step. This opens up new market possibilities for our customers and their clients: innovative applications for rigid PVC profiles, or more attractive pricing thanks to the low cost of this high grade material".