Out of the numerous excellent contributions that applied for LayTec first In-situ Monitoring Award, an independent committee recognized the contribution of Henning Döscher on In-situ quantification of the surface domain structure of thin GaP films grown on Si(100). The work is the result of a close collaboration of Henning Döscher and Thomas Hannappel (Helmholtz-Center Berlin for Materials and Energy, Germany) with Bernardette Kunert, Kerstin Volz and Wolfgang Stolz (Philipps-University Marburg, Germany).

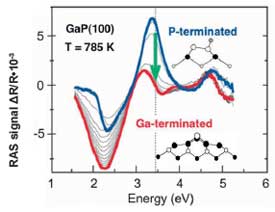

RAS spectra of GaP(100) surfaces in the MOCVD reactor. Temporal

development of a continuous change from the P-rich, hydrogen-

terminated (2x1) (blue curve) to the Ga-rich, (2x4) mixed-dimer

surface reconstruction (red) at 785 K without TBP supply.

RAS spectra of GaP(100) surfaces in the MOCVD reactor. Temporal

development of a continuous change from the P-rich, hydrogen-

terminated (2x1) (blue curve) to the Ga-rich, (2x4) mixed-dimer

surface reconstruction (red) at 785 K without TBP supply.

LayTec’s president Thomas Zettler granted the Award together with the cheque for 1000 Euros at the ICMOVPE 2008 in Metz, France on June 5. We congratulate Mr. Döscher and his co-workers on their success! The committee recognized Mr. Döscher‘s talk as a pioneering work in the fundamental research which will have a profound impact on future development of III-V semiconductors on Si substrates for future CMOS generations and solar cells. The key issue that the team tackled is the quantitative in-situ measurement of the density of anti-phase domains (APDs) during III-V-epitaxy on Si(100). The analysis of in-situ RAS peak intensities was used for a quantitative measurement of the APD concentration of thin GaP(100) films grown on Si(100) substrates (Figure).

For the study, the research team established correlations between RAS “fingerprints“ and the corresponding surface reconstruction domains under MOCVD growth conditions. When growing standard (P-rich) GaP on Si(100), the peak intensity at 3.4 eV (Fig. 2) correlates directly to the density of APDs. The maximum RAS amplitude of the P-terminated surface corresponds to a 100% single domain GaP surface. The RAS value of of the P-terminated surface shrinks down to zero for a 50:50% distribution of both types of surface domains. These results provide information about the initial Si(100) surface reconstruction domain ratio prior to GaP epitaxy because the atomic structure of the Si substrate is a major origin of the detected antiphase disorder. Other talks nominated for the prize will be summarized in the upcoming newsletters.