Oct 8 2013

An innovative mould for the series production of lightweight fibre composite parts has been developed by Georg Kaufmann AG, Busslingen/ Switzerland, within the scope of a joint project that goes by the name of LIPA (Lightweight Integrated Process Application).

Cut-to-size blanks of Tepex organic sheet – a fabric-reinforced thermoplastic – are first pre-heated and then placed in the mould, where they are thermoformed and at the same time provided with moulded-on ribs, bearing eyes and other working parts with the aid of the long-fibre direct injection moulding process developed by the firm of Arburg, Loßburg/Germany. The result is a lightweight part of extremely high strength and stiffness. The entire production process will be demonstrated at K 2013 (Düsseldorf, 16th to 23rd October 2013) on the Arburg exhibition stand (A13 in Hall 13) on a hydraulic Allrounder 820 S equipped with servo hydraulics. The machine and mould will be producing a demonstration part similar, for example, to a swing arm for a bicycle or a structural element in a car seat.

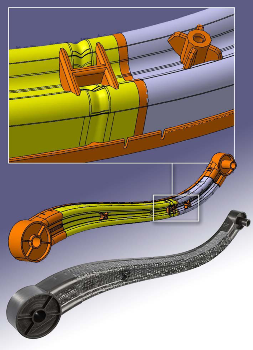

Demonstration lever; top: schematic depiction with enlarged detail of overlap area; bottom: actual lightweight fibre composite part. Source: Georg Kaufmann, Busslingen/Switzerland

Demonstration lever; top: schematic depiction with enlarged detail of overlap area; bottom: actual lightweight fibre composite part. Source: Georg Kaufmann, Busslingen/Switzerland

For the production of the demonstration lever, two cut-to-size organic sheet blanks of different thicknesses are gently heated up to thermoforming temperature in synchronism with the moulding cycle of the machine. A robot equipped with a vacuum gripper safely transfers the blanks with a minimum of delay into the mould cavity where they are thermoformed into a W-shaped profile. This not only increases the rigidity of the lever but also ensures a full-surface, firmly pressed, positive connection between the two component sheets. Stiffening ribs and an edging of long fibre-reinforced plastic are then injection moulded onto the organic sheets. As the temperature of the organic sheets is only slightly below the melting temperature of the base polymer, a perfect bond is ensured. For the same reason it is also possible to produce moulded-on elements (e.g. screw bosses) by injecting through the organic sheet without causing any damage to the fibre structure in the moulded part. In order that it can be connected to a mating part in a downstream process, the demonstration lever is provided with a corresponding hole during the moulding operation without adversely affecting the fibre structure.

In developing and producing this demonstration piece, the partners to the aforementioned joint project not only show that lightweight fibre composite parts can be mass-produced but also demonstrate a number of innovations that are decisive both for the economical efficiency and for the functionality of the parts:

- Improvement in the lightweight coefficient through local application of different thicknesses of organic sheet according to the load distribution within the moulded part.

- Reliable bond between the component organic sheets through full-surface, firmly pressed, positive connection.

- Creation of hole in the organic sheet without damaging the fibre structure.

- Encapsulation of the exposed fibres of the cut-to-size organic sheets through a moulded-on all-around edging.

- Reduction in heat-up temperatures for the organic sheet through minimum temperature loss during the moulding cycle.

- Long-fibre direct injection moulding readily permits flexible combinations of material through variations in fibre length and content.

- Significant cost benefits offered by long-fibre direct injection moulding thanks to use of cost-saving starting materials.

Project partners:

- Arburg: Injection moulding machine equipped with an injection unit in which the long glass fibres are cut and mixed into the melt directly from the roving

- Bond Laminates: Fabric-reinforced sheets with thermoplastic matrix (Tepex organic sheet)

- FPT Robotik GmbH & Co. KG: Design and production of process automation system

- Georg Kaufmann Concept GmbH: Part design; Moldflow simulation of injection moulding operation

- Georg Kaufmann Formenbau AG (LIPA initiator): LIPA mould, process design and engineering

- HRS: Hot runner system with needle valve nozzles suitable for LFRTs

- ILK/LZS GmbH: Calculation and simulation of the part

- Kistler Instrumente AG (LIPA partner): Mould sensor technology

- Krelus Infrared (LIPA partner): Infrared heater and control unit

- Lanxess Deutschland GmbH: Cutting pattern organic sheet, drape simulation of the part

- SKZ - KFE gGmbH: Process monitoring and quality control