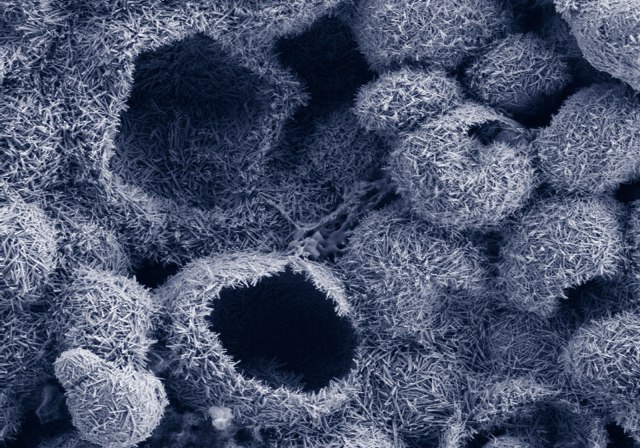

Hollow spheres of aluminum oxide are filled with gas. Scientists have developed an economical way of manufacturing these insulators. © Fraunhofer ICT

Hollow spheres of aluminum oxide are filled with gas. Scientists have developed an economical way of manufacturing these insulators. © Fraunhofer ICT

Researchers at the Fraunhofer Institute for Chemical Technology ICT have developed a novel, cost-effective coating technique using micro-scaled conjoined hollow aluminium oxide spheres to protect components against heat and oxidation.

Steam and gas turbines, reactors, temperature sensors, waste incinerator generators and combustion chambers are subjected to temperatures as high as 1000°C, and the new coating technology will benefit in these applications.

Due to the gas-phase insulation effect, gases are comparatively less conductive of heat than solids. They have been used in aerated or cellular concrete for keeping buildings warm. The same effect has been used by the research team for protecting components that are subject to intense heat. They used hollow conjoined aluminium oxide spheres filled with gas to create an outer topcoat for the coating. When the component’s outer side was exposed to 1000°C temperature, these spheres reduced the temperature on the components inner side to less than 600°C.

Most traditional thermal barrier techniques are expensive as they use ceramic materials. The new technique is cost-effective as it is based on an economic, conventional process that was meant for protecting components against oxidation. This process was optimized to also protect against heat.

Up to now, it never occurred to anyone to use these spheres to produce another coating layer – they were just a waste product.

Dr. Kolarik

The researchers deposited aluminum powder on the surface of the metal and heated it for several hours at an appropriate temperature to form a coating. A topcoat with hollow aluminum oxide spheres was also formed, and this provides protection against oxidation. They further refined the process to produce coating layers with the desired thickness. Aluminum particles and a viscous liquid bonding agent were mixed together and this slurry was then painted on to the components. In this process, the sizes, as well as, size distribution of the particles; the duration of heating and the appropriate temperature required for heating; and the bonding agent’s viscosity played a determining role in this process.

Fraunhofer researchers are presently applying findings from the PARTICOAT project to coat bigger components and are also developing methods to automate the coating process.

References