Jan 22 2015

Image Credit: nikkytok / Shutterstock.com

Image Credit: nikkytok / Shutterstock.com

Engineers at Trinity College, Dublin are leading a European Space Agency (ESA) project that aims to fine-tune revolutionary ‘Cold Spray’ 3D printing technology. The €500,000, four year project intends to develop this technology which will enable the production and coating of mechanical structures with different materials.

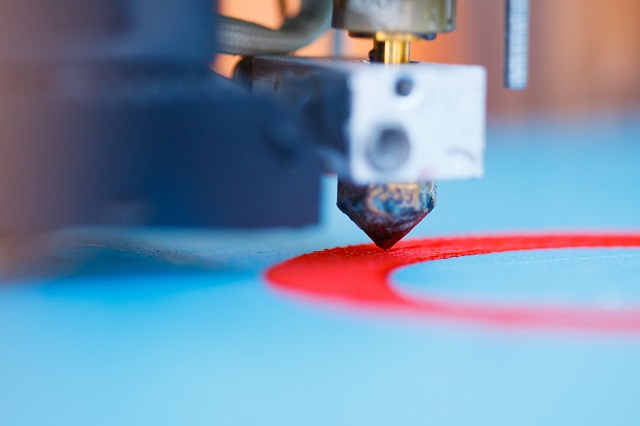

The Cold Spray (CS) technology will be useful for normal everyday household applications, on transport vehicles and on spacecraft that are in outer space. In CS technology, powders of desired materials are accelerated at supersonic speeds and then fired onto structures through a nozzle.

Currently this technology can be used for building simple geometrical components or coatings from different types of materials including metals, polymers and composites. When compared to other 3D-printing or additive manufacturing technologies, the CS technology is estimated to allow around 1,000 times faster production.

This process does not need heat, and hence microstructural changes, distortions or heat-affected zones do not occur. This provides significant advantages for the end product. However, the CS process is inefficient and costly. The Trinity team will be trying to reduce the costs involved in the CS process.

The team of engineers at Trinity College Dublin will be collaborating with numerous national companies regarding the technical aspects of the project.

The CS technology will benefit many Space science missions including the ExoMars, the Solar Orbiter missions, the International Space Station, the James Webb Space Telescope, Euclid, and Juice missions. Further, CS technology will also help create new multi-material objects and also enhance the surface properties of engineered components.

This is the largest ESA research project awarded to Trinity, and we will bring CS to the next level. Not only will we bring down its cost through the development of innovative solutions, but we will also enhance its technical capabilities for use in Additive Manufacturing, which was recently ranked as a top 10 breakthrough technology by MIT’s technology review.

Dr Rocco Lupoi, Assistant Professor in Mechanical and Manufacturing Engineering in Trinity’s School of Engineering

The CS technology would provide significant advantages to a large number of applications in space. This technique will also help manufacture 3D components at low-cost when appropriate level of robotic stage design and automation is used. The technological bottlenecks faced while using this technology will be addressed by the concepts obtained from this project.

Once developed, the new form of cold spray manufacturing could unlock new capabilities in coated materials, as well as multi-material combinations currently not possible.

Head of Strategic and Emerging Technologies Team at ESA, Professor David Jarvis

Dr Lupoi, Dr Shaun McFadden and Dr Anthony Robinson, all at Trinity are leading the project. They are Assistant and Associate Professors in Mechanical and Manufacturing Engineering. They will be collaborating with Professor David Jarvis, Mr Andrea Amaldi and Dr Wayne Voice who are Technical Officers at the ESA.