May 20 2015

Researchers from the Rice University have upgraded a microsupercapacitor with a blend of boron and laser-induced graphene, and this may soon find applications in the personal as well as wearable electronics market.

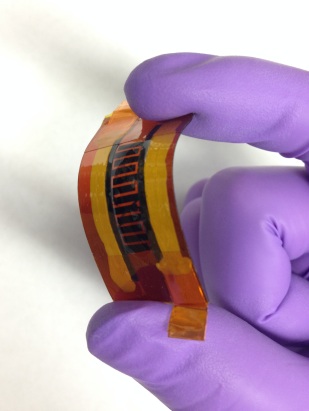

Rice University scientists made this supercapacitor with interlocked “fingers” using a laser and writing the pattern into a boron-infused sheet of polyimide. The device may be suitable for flexible, wearable electronics. (Credit: Tour Group/Rice University)

Rice University scientists made this supercapacitor with interlocked “fingers” using a laser and writing the pattern into a boron-infused sheet of polyimide. The device may be suitable for flexible, wearable electronics. (Credit: Tour Group/Rice University)

Thin, flexible supercapacitors were developed in the Rice lab of chemist James Tour with the aid of commercial lasers which were used to burn patterns into ordinary polymers. Everything is burnt off by the laser leaving behind only carbon to a depth of 20µm on the top layer. This carbon forms a foam-like matrix consisting of intertwined graphene flakes.

Before the laser process, the Rice researchers infused the polymer with boric acid to quadruple the supercapacitor’s storage capacity of electrical charge as well as to enhance its energy density. This uncomplicated manufacturing technique can also be adopted for manufacturing components for solar cells and lithium-ion batteries, catalysts and field emission transistors.

Capacitors tend to charge very fast and discharge their energy, just like a camera flash. In addition, supercapacitors provide the high-energy capacity of batteries to the package, and can be applied in electric vehicles and similar heavy-duty applications. The researchers state that the possibility to reduce the size of these supercapacitors into compact, flexible, easily manufactured packages, make them an ideal choice for multiple applications.

Previous research on polymers conducted by Rice graduate student Zhiwei Peng and team revealed that a commercial polyimide would be the most suitable option for the technique. The current Rice research experiment dissolved boric acid into polyamic acid. Then they condensed it to form a boron-infused polyimide sheet, which was subsequently exposed to the laser.

The two-step technique enables microsupercapacitors to be produced with four times more electrical charge storage and about five to ten times the energy density of the former boron-free model. The novel products have been proven to be very stable over 12,000 charge-discharge cycles with the ability to retain 90% of their capacitance. The researchers explained that even in stress tests, these products were able to withstand 8,000 bending cycles without any loss of performance.

Tour added that this technique to manufacture microsupercapacitors can be expanded to industrial-scale, roll-to-roll production.

What we’ve done shows that huge modulations and enhancements can be made by adding other elements and performing other chemistries within the polymer film prior to exposure to the laser.

Once the laser exposes it, those other elements perform new chemistries that really increase the supercapacitor’s performance. This is a step in making these even more amenable for industrial applications.

James Tour

Co-authors of the paper are Rice graduate students Ruquan Ye, Dante Zakhidov and Yilun Li; alumni Jason Mann, a research chemist at Exxon Chemical, and Jian Lin, an assistant professor at the University of Missouri; and Preston Smalley, a student at Second Baptist School, Houston.

Tour is the T.T. and W.F. Chao Chair in Chemistry as well as a professor of materials science and nanoengineering and of computer science and a member of Rice’s Richard E. Smalley Institute for Nanoscale Science and Technology.

The Air Force Office of Scientific Research and its Multidisciplinary University Research Initiative supported the research.

The research findings can be found in detail in the American Chemical Society journal ACS Nano.

References