Sep 3 2015

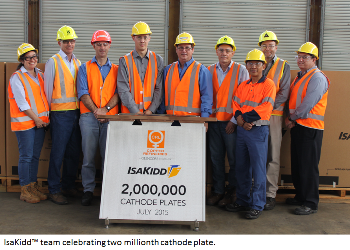

Glencore’s Townsville Copper Refinery and technology teams celebrated the manufacture of the two millionth ISA Cathode plate last month, representing over 40 years of development that has transformed the global copper industry.

2 millionth plate - team

2 millionth plate - team

The development of IsaKidd™ stainless steel cathode technology, initially known as the Isa Process™, started at the Townsville Copper Refinery between 1977 and 1978, with the gradual replacement of the original copper starter plate technology. Full conversion to IsaKidd™ was completed in 1979.

At the time, the decision to convert one of the world’s largest copper refineries to a new technology was a courageous one, considering the backdrop of a world economy bordering on recession after the oil price shocks of the mid-1970s.

However, pioneers of the technology needed to have a better and more efficient method for making high purity copper, and their skill and foresight created what was to become the cornerstone technology of the copper refining industry. The move also enabled cost effective and high purity copper production through SXEW.

The success of the technology at the Townsville Copper Refinery soon saw it licenced to other copper producers, with the first licence agreement signed with White Pine, USA, for its copper refinery conversion in 1982.

The rapid take-up of the technology within the copper industry saw sales following soon after to several world renowned refineries in Europe and the Olympic Dam operation in South Australia.

Glencore Technology’s ISA Cathodeshave now been installed worldwide, with over nine million tonnes per annum of copper cathode capacity installed in 26 countries across 76 different refinery and electro-winning operations.

The patented IsaKidd™technology includes plates, stripping machines, electrode handling equipment and services, with the technology still being developed. Advances include the development of duplex cathodes and robotic stripping machines.

Reinhardt Viljoen, Chief of Technology at Glencore Technology, says achieving the two millionth plate manufacturing milestone at the Townsville facility could not have been possible without the dedication and hard work of the Townsville Copper Refinery and Glencore Technology teams.

“It was this innovation and enthusiasm to create a better and improved process that led to this technology,” Mr Viljoen said.

“The result has been new innovations, such as the recently released IsaKidd™ hanger bar, which offers further efficiency gains for our clients.

“It has also enabled Glencore Technology to be one of the largest suppliers of cathode plates over the last 30 years, with manufacturing facilities established overseas as well as in Townsville, producing quality plates to high manufacturing standards our clients demand.

“We thank all ourpeople, past and present, who have contributed so much to make this achievement possible over the past 40 years.”