Oct 6 2015

Nanocellulose composites have been promised as the next supermaterial, though recent efforts to produce the material have been disappointing. An innovative, multi-scale computational test has been created which allows a "materials-by-design" approach in the development of nanocomposites with optimised properties.

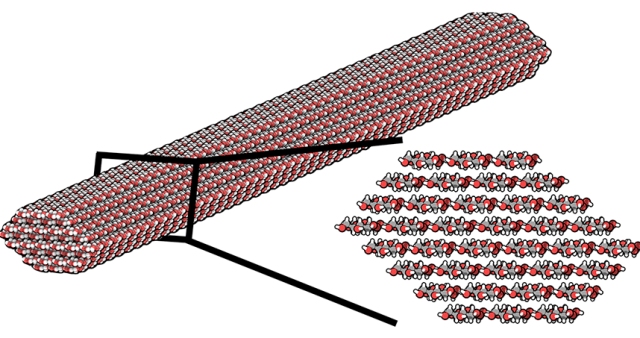

An illustration of a single cellulose nanocrystal and cross-section.

An illustration of a single cellulose nanocrystal and cross-section.

Nanocellulose could theoretically be considered to be the next supermaterial. Cellulose nanocrystals are found mostly in trees and but they are also present in lots of other natural systems. They have caught researchers attention as a supermaterial die to their super-high strength, toughness, elasticity and low weight. Cellulose nanocrystals are being hailed as a possible replacement for the Kevlar material that is widely used in the military for combat helmets and ballistic vests. Cellulose nanocrystals are also transparent meaning they could be used for displays, windows and protective eyewear.

It’s difficult to make these theoretical properties materialize in experiments. Researchers will make composite materials with nanocellulose and find that they fall short of theory

Sinan Keten - Northwestern University’s McCormick School of Engineering

Cellulose nanocrystals are found within the cellular walls of wood. They are considered to be promising as polymer nanocomposites; materials with nanoscale filler particles embedded within a synthetic polymer matrix. Nanocomposites can be used to produce a wide variety of useful products including biomaterials and tires. They are typically composed of carbon black, silica or clay.

Cellulose nanocrystals are an attractive alternative because they are naturally bioavailable, renewable, nontoxic, and relatively inexpensive. And they can be easily extracted from wood pulp byproducts from the paper industry.

Sinan Keten - Northwestern University’s McCormick School of Engineering

However, significant difficulties are faced when attempts are made to combine the polymer matrix and the nanocellulose filler particles. The way in which the filler quantity affects the properties of the composite material, and the nanoscale interactions that take place between the filler and the matrix are not clearly known.

The method developed by the research team at Northwestern University’s McCormick School of Engineering provides a better understanding of this problem. It does not concentrate on the material’s nature, but rather on the material’s length scales. The team’s computational approach could help predict the properties of the nanocomposites when it increases in size, by analyzing the factors that affect the material at the atomic scale. This also reduces the amount of experimentation required.

Rather than just producing a material and then testing it to see what its properties are, we instead strategically tune design parameters in order to develop materials with a targeted property in mindWhen you are equalizing music, you can turn knobs to adjust the bass, treble, etc. to produce a desired sound. In materials-by-design, we similarly can ‘turn the knobs’ of specific parameters to adjust the resulting properties.

Robert Sinko - Northwestern University’s McCormick School of Engineering

The study paper has been published in Nano Letters. The co-first authors of the paper are Wenjie Xia and Xin Qin, graduate students in Keten’s lab.

The National Institute of Standards and Technology, and the Army Research Office have supported the study.