Researchers have discovered that the manufacturing time for ultrathin Bulk Heterojunction (BHL) films can be significantly reduced by the addition of a simple solvent. The solvent removes the need for time-intensive annealing steps in BHJ film production. The new BHJ films, which are used widely in solar cells, are more efficient than ones produced using annealing.

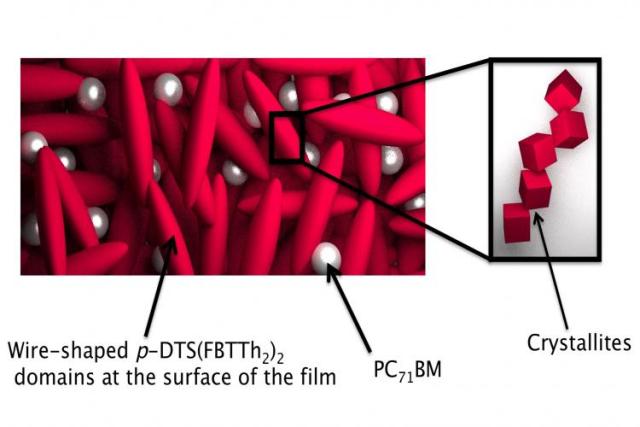

Fullerenes appear as small silver spheres spread consistently throughout a network of small molecules, or polymers, in this schematic illustration of the morphology of a BHJ film with solvent additives. Credit: ORNL.

Fullerenes appear as small silver spheres spread consistently throughout a network of small molecules, or polymers, in this schematic illustration of the morphology of a BHJ film with solvent additives. Credit: ORNL.

Semiconductor devices and solar panels have become less expensive and more efficient due to significant advances in ultrathin films. ORNL researchers state that they have discovered an easy way to make the ultrathin films needed for solar cells.

Organic Bulk Heterojunction (BHJ) solar cells use films to convert solar energy into electricity. These films are usually created by mixing fullerenes and conjugated polymers in solution. Fullerenes (also known as buckyballs) are soccer ball-shaped carbon molecules.

In order to ensure uniformity, the solution is spin cast onto a rotating substrate. Following this the mixture is then annealed. Annealing involves the heating and subsequent cooling of a material. This process increases the materials toughness whilst reducing its hardness, which allows the material to be easily worked with.

BHJs are pliable, which makes them preferable when compared to highly expensive crystalline silicon. However, the process of annealing requires a considerable amount of time. The research team states that the addition of a simple solvent, 1-8-diiodooctane (DIO), could remove the necessity of performing the time-intensive annealing process.

Nuradhika Herath, a postdoctoral researcher, led a team of material and neutron scientists from Oak Ridge National Laboratory (ORNL) to study the morphology of BHJ films.

Optimizing a film’s morphology is the key to improving device performance. What we want to find out is the relationship between the blend structures and photovoltaic performance.

Nuradhika Herath - ONRL

She added that finding out ways to tune the morphology of the film was as important as finding out the why certain film morphologies were performed better.

Their new method that for dissolving the fullerenes was compared with the thermal annealing process. The team wanted to obtain a film that had a uniform mixture of fullerenes and light absorbing molecules.

The uniformity of the mixture is very important as clusters can form that reduce the films efficiency. Clusters can absorb electrons that pass through and reduce the ability of the film to transport electrical current, affecting the overall performance of the device.

The ultrathin films are approximately 100 nm thick and their composition has a complex depth profile. To study the films morphology the team employed neutron scattering.

At CNMS, the researchers mixed two different samples and then spin cast them. One sample had a solvent additive, whilst the other was annealed. These film samples were then examined under the SNS’s Magnetism Reflectometer (MR), beam line 4A.

The exact way in which the fullerenes and polymers were arranged throughout the films was determined by the structural profiles provided by the MR. The researchers could clearly observe a difference.

In the annealed sample a considerable amount of separation was observed between the fullerenes and polymers. Whereas, in the solvent additive sample the morphology revealed extraordinary consistency throughout; which meant a better performance.

The reason is that when we use a solvent instead of annealing, the sample dries very slowly, so there is enough time for the system to become fully optimized. We see that additional annealing is not necessary because, in a sense, the system is already as perfect as it can be.

Valeria Lauter - ONRL

Many materials appear transparent to neutrons making neutron reflectometry an important technique for materials analysis. Neutrons can pass through the atomic structure of the material and provide quantitative and qualitative information on its composition. The data provided by the neurons would serve two purposes – they can be used to enhance the performance of the solar cells and also to streamline the manufacturing process.

The team concluded that solvent additives could help optimize the structure of the BHJ films and help reduce the production time, the resources required and the cost involved.

In addition, optimization of photovoltaic properties provides information to manufacture solar cells with fully controlled morphology and device performance. These findings will aid in developing ‘ideal’ photovoltaics, which gets us one step closer to producing commercialized devices.

Nuradhika Herath - ONRL

The research paper has been published in the journal Scientific Reports.

The coauthors of the study include Jong K. Keum, Rajeev Kumar, Bobby G. Sumpter, Kai Xiao, Sean Smith, Jiahua Zhu, Valeria Lauter, Ilia N. Ivanov, Pooran Joshi, and James F. Browning, all from ORNL; and Gong Gu and Sanjib Das from the University of Tennessee.