Apr 27 2016

Martin Thuo, an assistant professor of materials science and engineering at Iowa State University, is passionate about finding new, clean and affordable ways to put technology and science to work around the world.

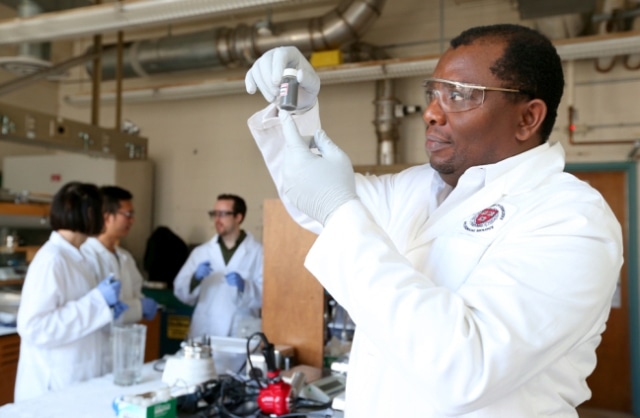

Martin Thuo holds a vial of the liquid-metal particles produced by his research group. Working behind him are, left to right, Simge Cinar, Jiahao Chen and Ian Tevis. (Photo by Christopher Gannon)

Martin Thuo holds a vial of the liquid-metal particles produced by his research group. Working behind him are, left to right, Simge Cinar, Jiahao Chen and Ian Tevis. (Photo by Christopher Gannon)

The professor’s laboratory is exploring a new concept called frugal innovation.

How do you do very high-level science or engineering with very little? How can you solve a problem with the least amount of resources?

Martin Thuo, Assistant Professor of Materials Science and Engineering, Iowa State University

Keeping this objective in mind, Thuo and his research team are utilizing their materials knowledge to analyze renewable energy production, single-molecule electronics, and soft matter. A supporting principle is that , whenever possible, nature should do some of the work.

Nature has a beautiful way of working for us. Self-assembly and ambient oxidation are great tools in our designs.

Martin Thuo, Assistant Professor of Materials Science and Engineering, Iowa State University

The researchers have recently developed a new method to produce micro-scale, liquid-metal particles. These metal particles can be utilized for heat-free soldering as well as for fabricating, processing, and repairing metals, all of which can be carried out at room temperature.

The study has been published in an online journal Scientific Reports. Thuo’s co-authors are Simge Cinar, a postdoctoral research associate; Ian Tevis, a former postdoctoral researcher who is now a chief technical officer at an Ames startup called SAFI-Tech; and Jiahao Chen, a doctoral student. This group has a tie up with Iowa State.

According to Thuo, Iowa State is a perfect place for making innovative developments in soldering technology. In 1996, a lead-free solder was patented by a research team headed by Iver Anderson of the Ames Laboratory and Iowa State’s department of materials science and engineering. Although that patent expired in 2013, the lead-free solder technology was licensed by over 50 companies in 13 countries.

Thuo expects that this heat-free soldering technology would be just as useful as the lead-free solder technology. To make this happen, Thuo partnered with Tevis to establish a new company called SAFI-Tech, which, according to Thuo, would be located at the Iowa State Economic Development StartUp Factory when it starts operations in ISU Research Park later this year.

The idea of a lead-free solder technology originated when researchers were looking for a way to prevent liquid metal from returning back to a solid state at temperatures below the metal’s melting point. This process is known as undercooling and has been extensively researched to gain a better understanding about metal processing and metal structure. However, the production of undercooled metals in large and stable quantities continued to be a major problem.

Thuo’s research group believed that covering small droplets of liquid metal with a thin and uniform coating layer could lead to stable undercooled liquid metal particles. The team then went on to try out a new method, which employs a high-speed rotary tool to sheer liquid metal particles into droplets inside an acidic liquid.

Nature plays a vital role at this stage. On exposing the metal particles to oxygen, a layer of oxidation covers these particles, producing a capsule-like structure containing the liquid metal. This layer is subsequently polished until it becomes smooth and thin.

To prove this new concept, Thuo’s research developed liquid-metal particles that included an alloy of bismuth, indium and tin (Field’s metal) as well as particles comprising of an alloy of tin and bismuth. The diameter of these particles measured 10 µm, which was approximately the size of a single red blood cell.

We wanted to make sure the metals don’t turn into solids, and so we engineered the surface of the particles so there is no pathway for liquid metal to turn to a solid. We’ve trapped it in a state it doesn’t want to be in.

Martin Thuo, Assistant Professor of Materials Science and Engineering, Iowa State University

The liquid-metal particles can have major implications in the manufacturing field. A patent has been filed by Thuo and the Iowa State Research Foundation.

“We demonstrated healing of damaged surfaces and soldering/joining of metals at room temperature without requiring high-tech instrumentation, complex material preparation or a high-temperature process,” the engineers wrote in their paper.

The study was supported through faculty startup funds from Iowa State and Black and a Veatch faculty fellowship. Imaging work was also involved in the project that was conducted at the Center for Nanoscale Systems at Harvard University in Cambridge, Massachusetts.

Tevis from SAFI-Tech startup informed that the company is still analyzing the liquid-metal technology for mechanical reliability and electrical conductivity. The company is also planning to develop the technology for other product demonstrations.

According to Thuo, the project represents a good example of a frugal approach to science: it should be inexpensive, sustainable, and practical, and should help innovate and solve problems.