Jul 25 2016

The Mexican automotive industry is growing steadily. The current trends in national technology used for the development of innovative materials provide an opportunity to enter into the international market. Mexican researchers have created products that help reduce the risks of injury in car accidents. These products are derived from the combination of metals that have porous characteristics and a "super elastic" capacity.

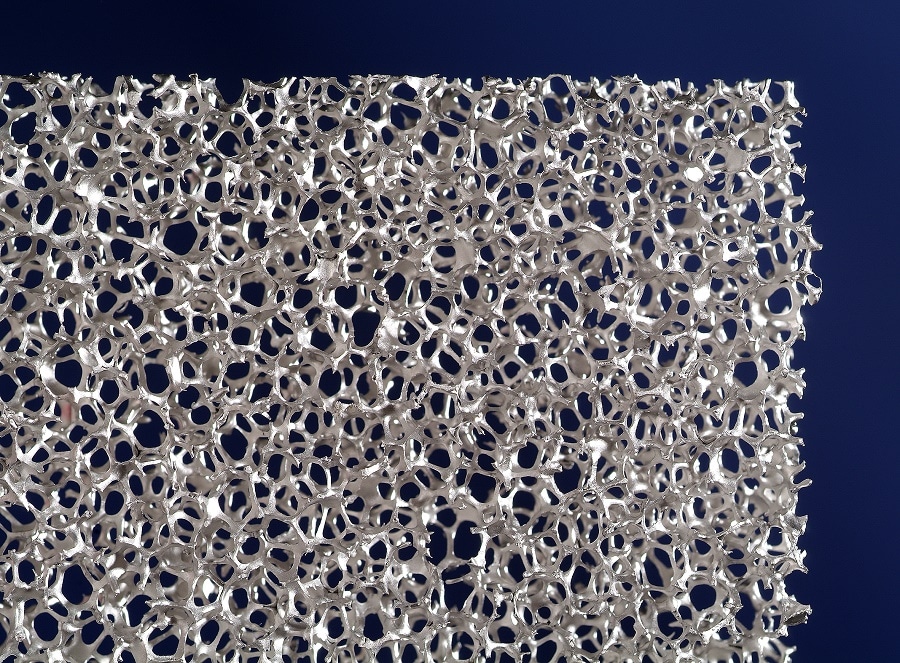

Espuma metaìlica, exotic car. Credit: Investigación y Desarrollo.

Espuma metaìlica, exotic car. Credit: Investigación y Desarrollo.

The researchers used denominated metal foam to create the Infierno Exotic Car. This material is developed using a method that transforms a compound, obtained from a previous combination of different metals, such as aluminum, copper and silver, from liquid to solid state, creating a porous product.

According to doctor Said Robles Casolco, professor of the Universidad Autonoma del Estado de Morelos (UAEM), the products obtained from the mixture of these metals can be 'educated', in other words, they can be controlled or used for various applications. They can also be expanded 100 times more than their regular size and then return to their normal state.

These super elastic materials are a pattern of the geometric expression of nature, which can be imitated in technology. One of the main objectives of this research work is to create porous metal alloys with a capacity similar to sea corals, some rocks and bones, so that the metal foam can act as an impact absorber in strong impacts and then return to its normal state.

Most of the metal foam’s components are light weight so that the vehicle can reduce a large amount of effort needed to burn fuel, which minimizes the greenhouse gas emissions, such as carbon monoxide and oxide.

Other characteristics that make the Infierno Exotic Car innovative and different from other cars are its speed and complex designs. This car can achieve 395 kilometers per hour in three seconds, and this, together with its complex designs place it in an international market of the Mexican automotive industry.

The goal is to make designs different to those already known by the international audience. We try to prove that our technology is hand in hand with those of many other countries in the world.

UAEM Investigator

LTM HOT SPOT is the Mexican enterprise that designs the car as well as the metal foam that is already patented. The company is now planning to design and create electric cars with similar features to the metal foam. However, the metal foam material can also be adapted to the new type of cars available in the automobile industry.

The metal foam can also be used in the medical field by integrating it with hydroxyapatite ceramic for use as an implant, said Doctor Said Robles. The metal foam becomes biocompatible and can be used for hips due to its low density and low-cost. It is believed that this material can substitute titanium and other corrosive and heavy materials. “This material can be part of the new generation of implants in Mexico, and it would be an excellent industry”, concluded the specialist.

Source: http://www.invdes.com.mx/