Aug 9 2016

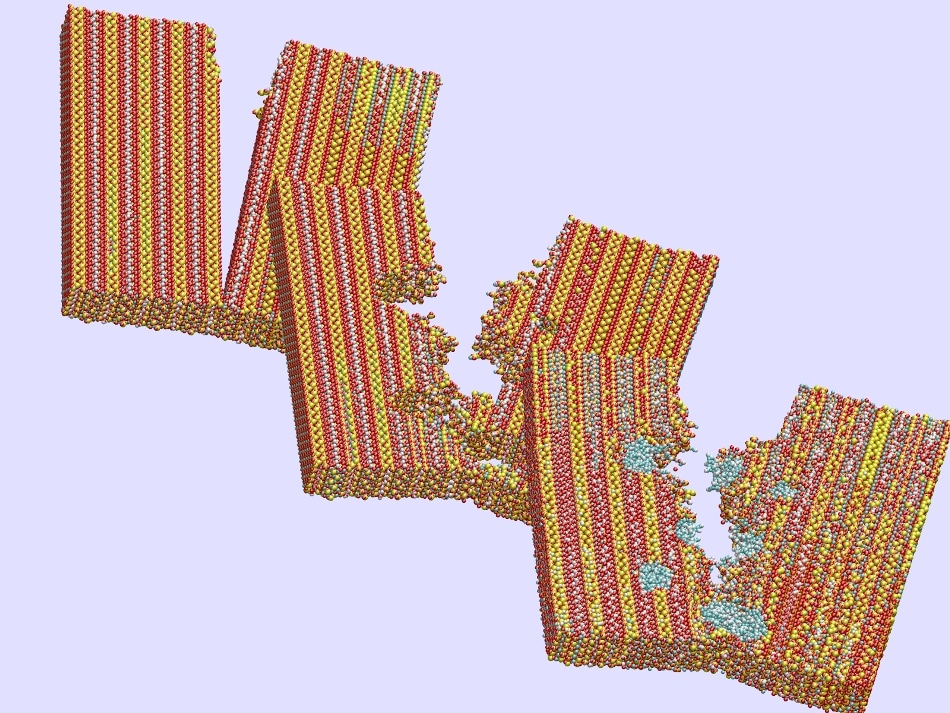

Rice University researchers analyzed more than 600 computer models of concrete’s inner matrix to determine how voids (center) and portlandite particles (right) impart strength and toughness by preventing the spread of cracks (left). (Image by Ning Zhang/Rice University)

Rice University researchers analyzed more than 600 computer models of concrete’s inner matrix to determine how voids (center) and portlandite particles (right) impart strength and toughness by preventing the spread of cracks (left). (Image by Ning Zhang/Rice University)

A lot of nothing, or something, is what is required to strengthen or reinforce concrete. The “nothing” part can be defined as microscopic voids and the “something” part has specific particles inserted into the most frequently used construction material on Earth.

Rice University materials scientist Rouzbeh Shahsavari and postdoctoral researcher Ning Zhang tested over 600 computer models of concrete’s inner matrix to establish that both voids and portlandite particles have a major role to play in providing the material its outstanding qualities.

The research is featured in the Journal of the Mechanics and Physics of Solids.

Shahsavari and his team aimed to offer new insights and to prepare guidelines and approaches to make the cement hydrate - known as calcium-silicate-hydrate (C-S-H) - at the core of concrete highly tunable from the molecules up. They discovered that although concrete tends to look brittle at the macroscale, it includes ductile fracture mechanisms at the nanoscale that help to maintain it from failing.

C-S-H is the smallest building block in concrete, and we want to understand and control it to our advantage. Modeling how its molecules interact helps us understand its nanoscale structure, defects and fracture toughness. But this is very difficult to study through experiments alone because of the scale of the features we’re looking at.

Rouzbeh Shahsavari, Materials Scientist, Rice University

This current research is a part of a series of studies from the Rice lab, and it analyzes how the contact of either random air voids or random portlandite particles in C-S-H manipulates the mechanical qualities of toughness, strength, stiffness, especially where voids encounter propagating cracks.

“Besides C-S-H, portlandite is another product of cement hydration, but it forms in lower quantities compared with C-S-H and mainly exists as sort of inclusions or isolated islands surrounded by the C-S-H matrix,” Shahsavari said. “Because portlandite has different crystalline features and mechanical properties than C-S-H, its presence and distribution can significantly impact the mechanics of C-S-H.”

With the help of molecular dynamics simulations, the team discovered that cracks generally followed the path of least resistance and turn towards either the nanovoids or portlandite particles they met.

By deflecting or altering the geometry of a crack, the particles and voids sapped the energy from the crack. Shahsavari stated that this probably contributed to the overall toughness of the concretes.

When it comes to cement hydrate’s strength and toughness - properties that are typically exclusive in man-made materials - random voids and portlandite particles play a key role by regulating a series of competing deformation mechanisms, such as crack growth, crack deflection, voids coalescence, internal necking, accommodation and geometry alteration of voids and particles. Our work decoded all such complex competing mechanisms.

Rouzbeh Shahsavari, Materials Scientist, Rice University

For C-S-H that is more amorphous than crystalline, they discovered that adding portlandite particles brought on strong chemical reactions that enhanced both the strength and the toughness of the product. By analyzing all the variations, they also established that the smaller the mean diameter of both particles and voids, the stronger the material.

As over 30 billion tons of concrete are used annually and its manufacture causes up to 10% of carbon dioxide emissions globally, the benefits from any tiny alteration is worth the effort, Shahsavari said.

Our results provide, for the first time, new evidence of ductile fracture mechanisms in cement hydrate that are reminiscent of crystalline alloys and ductile metals. Given that crack growth and strength are an inherent property controlled by nanoscale deformation mechanisms, our findings can impact the mechanical properties of concrete at larger scales, opening up new opportunities and strategies to turn brittle cement hydrate into a ductile material. This would impact the modern engineering of durable concrete infrastructures and potentially other complex brittle materials.

Rouzbeh Shahsavari, Materials Scientist, Rice University

The research was supported by the National Science Foundation, the National Institutes of Health and an IBM Shared University Research Award in partnership with CISCO, Qlogic and Adaptive Computing.

The researchers made use of the NSF-supported DAVinCI supercomputer administered by Rice’s Center for Research Computing and procured in a partnership with Rice’s Ken Kennedy Institute.