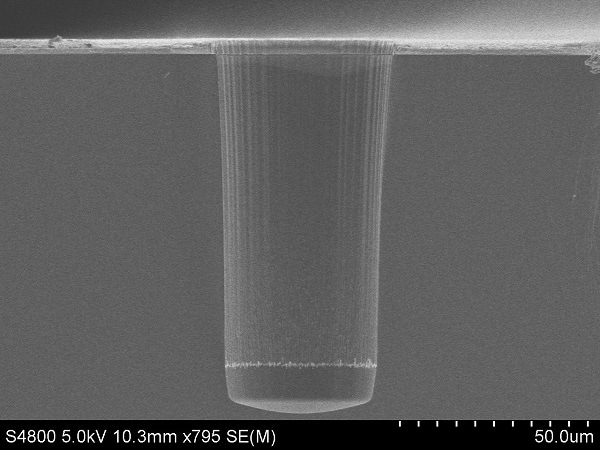

SEM showing smooth via etch through SiC

SEM showing smooth via etch through SiC

As a leading provider of process solutions for a broad range of applications, Oxford Instruments is delighted to announce the development and launch of the SiC via plasma etch process using its high performance PlasmaPro100 Polaris etch system.

SiC is becoming an increasingly important material, particularly in the arena of high performance GaN RF devices using SiC as a substrate. A smooth via etch through the SiC is essential to enable these devices, and Oxford Instruments has developed the ideal solution for etching high quality SiC vias efficiently.

Combined with a low damage GaN etch within the same hardware, the PlasmaPro100 Polaris offers a unique capability for GaN based RF device plasma etch processing requirements.

The technology developed offers several process capabilities suited to the SiC via application:

- High SiC etch rate enabling maximum throughput

- Smooth sidewalls for problem free post etch metallisation

- High selectivity to underlying GaN layer giving a smooth, low damage stop onto the GaN device layers

- Clamping of sapphire carriers using Oxford Instruments’ unique patented Electrostatic Clamp technology ensuring excellent sample temperature control and maximum yield

- Capability of etching SiC and GaN in the same tool through advanced plasma source technology

- High utilisation provided by long Mean Time Between Cleans (MTBC)

Our Applications specialists have spent significant time developing this SiC via etch process on the PlasmaPro100 Polaris etch system, enabling high selectivity and throughput amongst other benefits. These benefits will enable our customers to etch both SiC and GaN in the same tool through advanced plasma source technology.

Dr Mark Dineen, Optoelectronics Product Manager at Oxford Instruments Plasma Technology

Oxford Instruments delivers world leading plasma processing systems, and offers a library of over 6,000 process recipes, all backed by a global support and service network.

About Oxford Instruments Plasma Technology

Oxford Instruments Plasma Technology offers flexible, configurable process tools and leading-edge processes for the precise, controllable and repeatable engineering of micro- and nano-structures. Our systems provide process solutions for the etching of nanometre sized features, nanolayer deposition and the controlled growth of nanostructures.

These solutions are based on core technologies in plasma-enhanced deposition and etch, ion-beam deposition and etch, atomic layer deposition, deep silicon etch and physical vapour deposition. Products range from compact stand-alone systems for R&D, through batch tools and up to clustered cassette-to-cassette platforms for high-throughput production processing.