Oct 12 2016

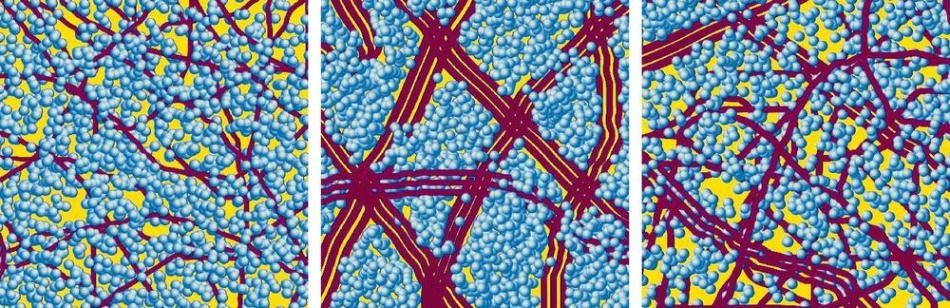

The inner structure of the active layer without solvent additive (left), with solvent additive (centre) and after loss of solvent additive (right). Losing the solvent leads to an inner structure comparable to production without solvent. Credit: Christoph Schaffer / TU Munchen

The inner structure of the active layer without solvent additive (left), with solvent additive (centre) and after loss of solvent additive (right). Losing the solvent leads to an inner structure comparable to production without solvent. Credit: Christoph Schaffer / TU Munchen

The accurate X-ray vision offered by DESY’s radiation source PETRA III has been used by researchers from the Technical University of Munich to examine the degradation of plastic solar cells.

Their research recommends a technique for enhancing the manufacturing process in order to increase the prolonged stability of these organic solar cells. Headed by Prof. Peter Müller-Buschbaum, the team presented its results in the recent issue of the scientific journal Advanced Energy Materials (Vol. 6, No. 19, published online in advance).

In comparison to the standard solar cells produced from silicon, organic solar cells generate electricity in an active blended layer existing between two carbon-based materials. The resulting cell is often regarded as a plastic solar cell when one of these is a polymer.

These cells are promising as they can be manufactured in a cost-effective and simple manner. They also have the potential to develop semi-transparent, flexible and extremely lightweight solar cells using printing methods on flexible polymer materials, making room for totally new application fields.

However, organic solar cells are generally considered to be less efficient compared to silicon-based ones, and they also have a limited life span.

The active layer’s internal structure is significant in organic solar cells. During the manufacturing process of these cells, the two materials that develop the active layer must separate from a common solution, similar to droplets of oil forming in water.

It is important that the polymer domains formed in the process are a few tens of nanometres apart. Only then positive and negative charge carriers can be efficiently produced in the active layer and separated from each other. If the structure is too coarse or too fine, this process no longer happens, and the efficiency of the solar cell will decrease.

Christoph Schaffer, PhD Student, Technical University of Munich

Currently available polymer solar cells mostly consist of low-bandgap polymers, which mainly absorb huge amounts of light. In several cases, the use of a solvent additive is required during the manufacturing process in order to obtain high efficiencies. However, this additive is controversial as it could further reduce the life span of the solar cells.

DESY’s X-ray source PETRA III was used by the researchers to examine the degradation of such low-bandgap polymer solar cells comprising solvent additives in a detailed manner. A solar cell of this particular type was exposed to simulated sunlight in a chamber, and its chief parameters were consistently monitored.

At the same time, a narrowly collimated x-ray beam from PETRA III was shone by the researchers on the active layer on a nanometre scale every few minutes.

These measurements can be used to relate the structure to the performance of the solar cell and track it over time.

Professor Stephan Roth

Roth is in charge of DESY’s P03 beamline, where the experiments were conducted.

“The data reveals that domains that are on the scale of a few tens of nanometres shrink substantially during operation and that their geometric boundaries with other components disappear,” says Schaffer. Meanwhile, the measurements highlight that the amount of residual solvent additive reduces. The researchers attribute the measured drop in the effectiveness of the solar cell to the observed reduction.

“Since there is evidence to suggest that the residual amount of solvent additive decreases, we have to assume that this process can limit the lifetime of the solar cells,” explains Müller-Buschbaum. “Therefore it is essential to come up with strategies for stabilising the structure. This could be achieved through chemical bonding between the polymer chains, or using customised encapsulating substances.”

The degradation of a different type of polymer solar cell was studied by the researchers in a pervious study. They discovered a drop in the efficiency due to active centers gradually increasing in size during their operation. This pointed out the benefits of manufacturing such solar cells with a suboptimal structure, i.e. one that is extremely fine, such that is can grow to the optimum size during the initial working hours.

The present study develops on the story where the earlier one left off.

Our first study showed us that the efficiency dropped when the structure became coarser. Exactly the opposite happens in the present study. This behaviour is precisely what we expected, because the composition of the active layer is different. The materials in the first study tend to demix to a high degree. Here, the opposite is true, and we need the solvent additive in order to achieve the demixing of the materials that is needed to obtain high efficiencies. When the solvent additive disappears during operation, the structure becomes finer and therefore moves away from its optimum.

Christoph Schaffer, PhD Student, Technical University of Munich

These two studies provide significant approaches to optimizing the manufacture of organic solar cells, as co-author Roth points out: “The way these two studies fit together provides a wonderful example of how investigations with synchrotron radiation on the atomic scale yield crucial results, especially in applied research such as in the field of renewable energies.”