Nov 22 2016

Doctors carrying out medical check-ups need a complete status of a patient’s health without the need for scalpel. In a similar position are engineers who want to analyze the stability of a bridge, without cutting into it. As non-destructive testing techniques have a vital role in ensuring safety and quality, there is a significant need for refined methodologies. Scientists from the Technical University of Munich (TUM) have developed a new technique that provides an accurate picture of the inner world of objects by combining a computerized model and an experiment.

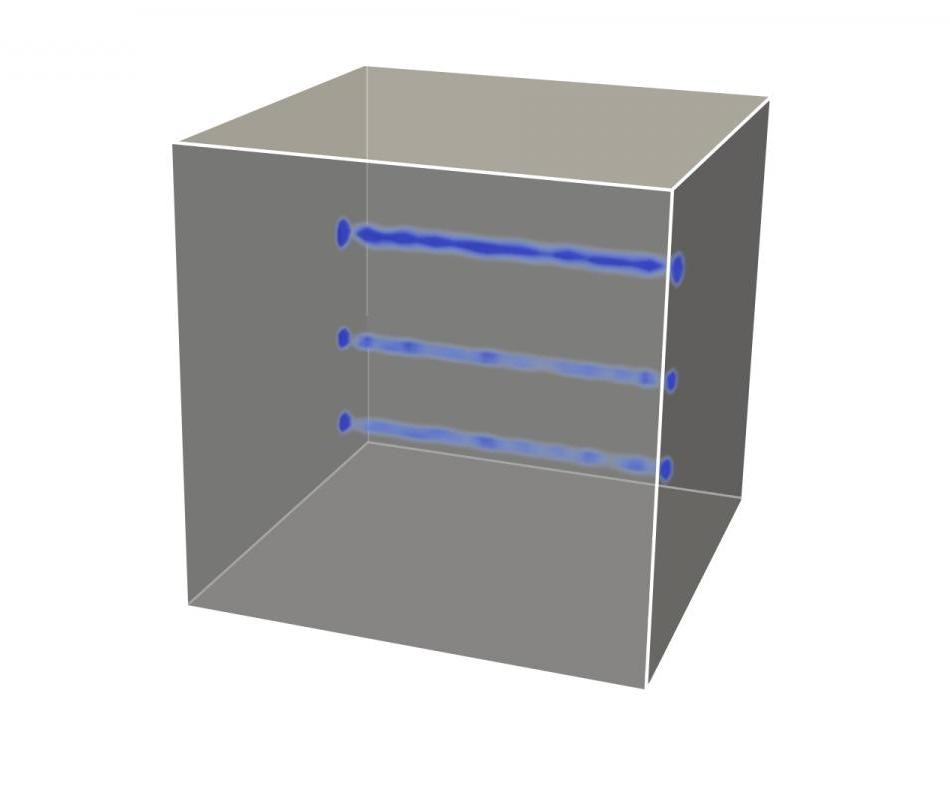

Computer simulation of ultrasound measurement of a concrete-cube. Credit: Chair for Computation in Engineering/TUM.

Computer simulation of ultrasound measurement of a concrete-cube. Credit: Chair for Computation in Engineering/TUM.

One of the most commonly used technologies for non-destructive testing is ultrasound measurement, which employs the same principle of echolocation that bats use to collect information related to prey and possible obstacles from their surroundings using ultrasonic sounds. The bat locates the direction of the object by sensing which ear detects the echo of a sound first. The angle between the object and the direction of the sound emitted is smaller if the time difference between the arrival of the signals at the respective ear is smaller. When the echo reaches with the same volume and at the same time at both ears, the object is situated exactly in the direction from which the sound was emitted.

Traditional non-destructive testing techniques employ the same principle to investigate structural defects by using ultrasound. Measurements determine the wavelength, speed, time difference with which the ultrasound waves or their reflections reach the sensors positioned on the surface of the target object. Then, variances are calculated by comparing these measurements with data obtained from a non-defective reference object.

This standard procedure can basically be used to identify and localize defects. But it only returns a limited amount of information on their exact position, extent and orientation.”

When the whole wave counts

To overcome this problem, the researchers mathematically modeled the material characteristics of the aluminum plates used in the experimental part of their project. Then, they employed this model to compute the propagation of both the ultrasound waves and their reflections. The virtually calculated values were compared with the outcomes of real experiments in which the ultrasound waves were made to pass through real aluminum plates.

They found out that there was a difference between the measured values of the real and virtual sensors. This is because special factors within in the structure can cause specific refraction or scattering of the ultrasound waves. The scientists employed a trick to overcome this error source. They reintroduced the difference between the measured virtual and real waves at the sensors as a signal to compute an improved model. This technique is known as wave form inversion, and makes use of the complete information content of the measured wave field.

The effort is worth it

First developed by the Spanish geophysicist Albert Tarantola in the 1980s, this technique was regarded, for a long time, as practically unfeasible as it requires very large amount of data. The recent developments in innovative algorithms and advancements in the field of computer technology have paved the way for realizing the highly computation-intensive application of wave form inversion.

We can surely ask ourselves whether the additional computational effort is worth it. But when we look at the benefits of our method, the answer has to be yes, the effort is more than worth it.

Robert Seidl, information scientist and mathematician

One of the key tasks of the near future will be applying and evaluating wave form inversion with real structures in the fields of mechanical engineering and construction. This is the objective of a research project, wherein Prof. Rank’s group will work in close cooperation with Prof. Christian Grosse’s group at the Chair of Non-destructive Testing (NDT).