Jan 4 2017

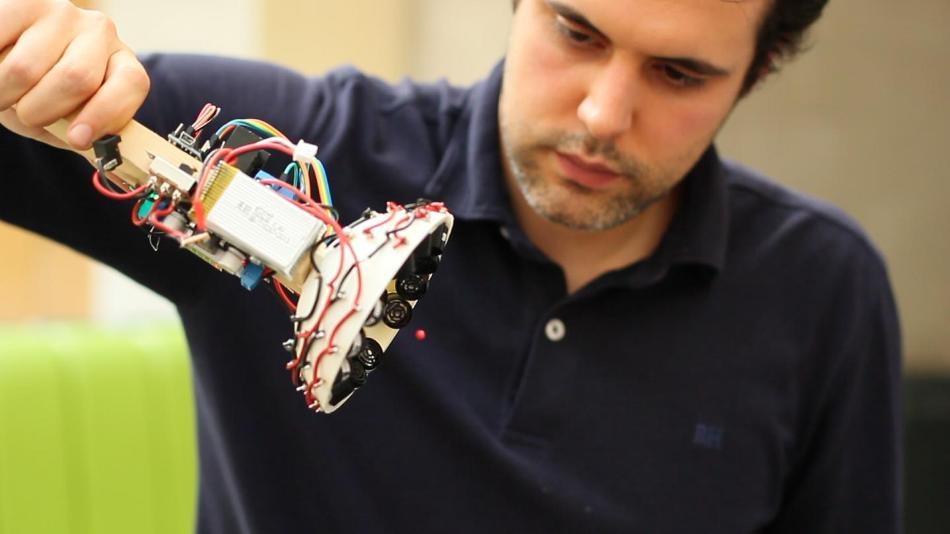

This image shows levitating a 3cm diameter expanded polysterine sphere with a DIY portable tractor beam. (Credit: Asier Marzo)

This image shows levitating a 3cm diameter expanded polysterine sphere with a DIY portable tractor beam. (Credit: Asier Marzo)

Last year, the first single-sided acoustic tractor beam - that is, the first achievement in trapping and pulling an object using sound waves from only one direction - was developed with the assistance from Asier Marzo.

At that time, Marzo was a doctoral student at the Public University of Navarre and is now a research assistant at the University of Bristol. Marzo has headed a group of researchers in adapting the technology to be 3D printable by any person, for all aims and purposes, but definitely not without some assembly.

A thoroughly detailed how-to video produced by the group for the public as well as the outcomes of the research in developing the do-it-yourself (DIY), handheld acoustic tractor beam will be published as an open access paper this week in the journal Applied Physics Letters (published by AIP Publishing).

Sonic levitation is not something unknown. The technique of using sound waves to push macroscopic objects around or to form patterns in flowing water and resting sand has been known for many years now. It is also found widely throughout YouTube. However, the technology is not merely sonic levitation, i.e. pushing objects around by using sound.

The tractor beams are based on similar fundamental physics applied for decades to form optical traps. As their name suggests, these beams literally pull objects, trapping small beads (and sometimes insects) at their foci.

The most important thing is that it can attract the particle towards the source. It’s very easy to push particles from the source, but what’s hard is to pull them toward the source; to attract the particles. When you move the tractor beam, the particle moves, but otherwise the trap is static. It can levitate small plastics; it can also levitate a fly and small biological samples. It’s quite handy.

Asier Marzo, Research Assistant, University of Bristol

The prototype versions of the device that demonstrated the plausibility of the concept were not very larger than the new, 3D printable versions. However, the basic technology behind the prototype versions was highly complex and required costly electronics.

A major portion of the cost was due to the array of active components for electronically shaping sound waves, which manipulated the manner and the place where the waves interfered to form the resulting object-trapping environment just above the array.

“Previously we developed a tractor beam, but it was very complicated and pricey because it required a phase array, which is a complex electronic system,” stated Marzo. “In this paper, we made a simple, static tractor beam that only requires a static piece of matter.”

The simplicity as well as the affordability of this passive, static-matter approach is due to the unique architecture of that matter, which is structured to substitute the phase array components and to structurally shape the sound waves and not electronically. When the sound - that can now be generated by a single source - passes through the cautiously structured elements, the internal structure of the 3D printed material shapes the waves.

We can modulate a simple wave using what’s called a metamaterial which is basically a piece of matter with lots of tubes of different lengths. The sound passes through these tubes and when it exits the metamaterial, it has the correct phases to create a tractor beam.

Asier Marzo, Research Assistant, University of Bristol

As this effect primarily depends on the shape of the tubes, the researchers concentrated on optimizing the design to enable the use of common 3D printers for fabrication, thus ensuring that even at-home hobbyists can construct the beam.

Marzo stated that this was fundamentally a challenge in resolution, necessitating a design that would not be affected by the limited precision of lower-end 3D printer nozzles. “We needed to engineer the tubes very well to allow them to be 3-D printed with a normal 3-D printer. A normal 3-D printer has a lot of limitations,” he stated.

After overcoming the limitations, the research team developed the remaining part of the tractor beam system by making use of easily accessible components manufactured by the popular open-source electronics supplier, Arduino. The team has also made a detailed how-to video related to its construction.

“There will be a set of instructions with a list of the needed components and a step-by-step video. The components are very simple, like an Arduino and a motor driver, and everything can be bought on Amazon for less than £50 (about $70),” stated Marzo.

The DIY tractor beams have a number of potential uses. They can even become a new tool for analyzing the effects of low gravity on biological samples. According to Marzo, “micro-gravity” research of this kind has already fascinated and motivated biologists to develop their own applications for the device.

Recently there have been several papers about what happens if we levitate an embryo, how does it develop? Or what happens if we levitate bacteria? For instance, they discovered salmonella is three times more [virulent] when it’s levitated. Certain microorganisms react differently to microgravity.

Asier Marzo, Research Assistant, University of Bristol

The device has been developed with three different designs with trapping profiles appropriate for objects of different sizes relative to the wavelength of sound used. Yet, even during the complete lab execution in which heavier objects and even liquids are trapped, it is still highly challenging to trap objects larger than half the wavelength of sound. In the case of practical frequencies - just above the hearing ability of humans - this restricts the size of trappable objects by a few millimeters.

At the time when Marzo and his team work to overcome the challenge and continue to enhance the capacity of their tractor beams, making their technology available to all will make way for limitless uses and improvisations from the maker community. Therefore, the actual question is—how will you put your own tractor beam to use?