Jan 4 2017

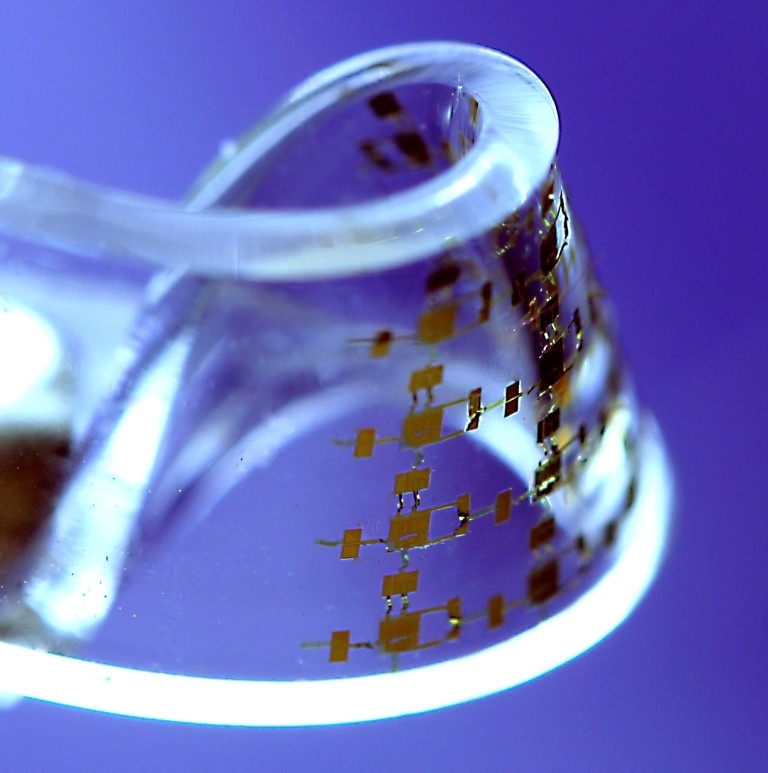

New bendable electronic devices like the one pictured above could become more common in the future. Photo by John Rogers, University of Illinois, courtesy of the National Science Foundation.

New bendable electronic devices like the one pictured above could become more common in the future. Photo by John Rogers, University of Illinois, courtesy of the National Science Foundation.

Electronic components that can be twisted or elongated are known as “stretchable” electronics. These could soon be used to power onboard systems of vehicles, electronic gadgets, medical devices, and other products. And according to researchers at Missouri University of Science and Technology, using a 3D printing-like approach to manufacturing could help make stretchable electronics more widespread.

In an article in the January 2017 edition of the Micromachines journal, the Missouri S&T researchers evaluate the existing state of the emerging field of stretchable electronics, focusing on a type of conductor that can be manufactured on or set into the surface of a polymer called elastomer.

There is a possibility that these conductors may soon replace the inflexible, brittle circuit board that powers many existing electronic devices. They could be used, for instance, as wearable sensors that stick to the skin to monitor brain activity or heart rate, as thin solar panels that could be plastered onto curved surfaces, or as sensors in clothing.

The essential factor to the future of stretchable electronics is the surface, or substrate. Elastomer is a flexible material possessing high elasticity, which means that it can be stretched, bent, twisted, and buckled repeatedly with less impact on its performance.

In their paper titled “Materials, Mechanics, and Patterning Techniques for Elastomer-Based Stretchable Conductors” (Micromachines 2017, 8(1), 7), the researchers discuss one challenge facing this group of stretchable electronics, which involves “overcoming mismatches” between the flexible elastomer base and highly brittle electronic conductors.

“Unique designs and stretching mechanics have been proposed to harmonize the mismatches and integrate materials with widely different properties as one unique system,” writes the research team, which is headed by Dr. Heng Pan, assistant professor of mechanical and aerospace engineering at Missouri S&T.

A fairly new manufacturing method known as additive manufacturing could help to resolve this problem, Pan says.

Additive manufacturing can be defined as a process that enables manufacturers to develop 3D objects, layer by layer – similar to 3D printing, but with ceramics, metals, or other materials. In their paper, the team recommends that very thin layers of extremely conductive materials can be printed onto an elastomer surface using additive manufacturing.

“With the development of additive manufacturing, direct writing techniques are showing up as an alternative to the traditional subtractive patterning methods,” the S&T researchers say.

Subtractive methods include photolithography, which is frequently used to manufacture semiconductors.

Pan and his colleagues believe that additive manufacturing is a comparatively economical method to developing these new devices. At Missouri S&T, they are analyzing a method that Pan refers as “direct aerosol printing.” The method involves spraying a conductive material and combining with a stretchable substrate to create sensors that can be placed on skin.

“With the increase of complexity and resolution of devices, higher requirements for patterning techniques are expected,” they write. “Direct printing, as an additive manufacturing method, would satisfy such requirements and offer low cost and high speed in both prototyping and manufacturing. It might be a solution for cost-effective and scalable fabrication of stretchable electronics.”

However, more challenges need to be looked into before stretchable electronics become extensively used as components in medical devices, consumer electronics, or other fields, the researchers say. These challenges include creating stretchable batteries that are capable of storing energy and ensuring that stretchable electronics and the malleable surfaces they are built upon function and wear well in unison.

However, Pan and his colleagues are positive about the progress of stretchable electronics. They anticipate a growth in a variety of materials that could be used as good conductors of electricity and as flexible surfaces on which to construct stretchable electronics.

Co-authors of the Micromachines paper are Xiaowei Yu and Wan Shou, both Ph.D. students in mechanical engineering at Missouri S&T, and Bikram K. Mahajan, a master’s student in mechanical engineering at Missouri S&T. Their research paper was first published online on 27 December 2016.