Feb 23 2017

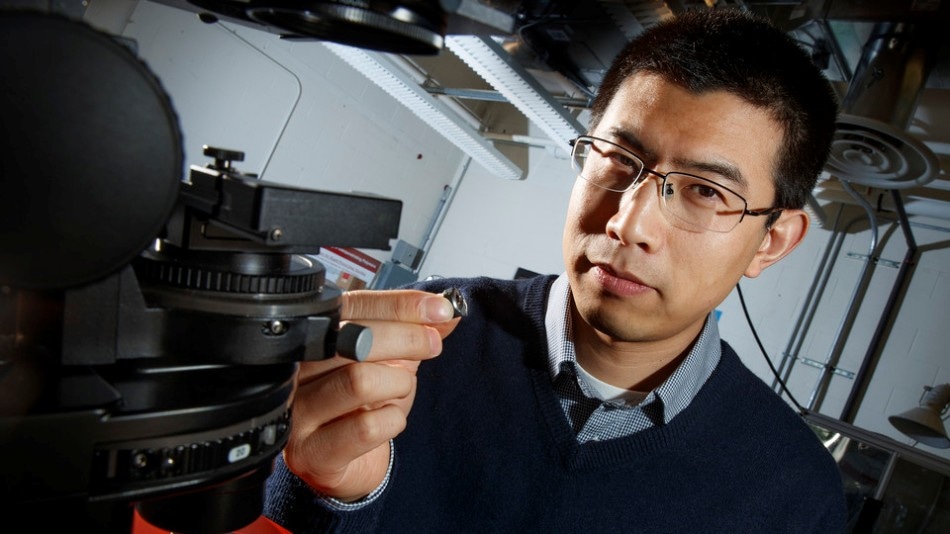

Ruiguo Yang, assistant professor of mechanical and materials engineering, and his colleagues found a way to analyze the fibrous nanostructure of beetles. Better understanding the structure and properties of beetle exoskeletons could help scientists engineer lighter, stronger materials. (Photo: Craig Chandler | University Communication)

Ruiguo Yang, assistant professor of mechanical and materials engineering, and his colleagues found a way to analyze the fibrous nanostructure of beetles. Better understanding the structure and properties of beetle exoskeletons could help scientists engineer lighter, stronger materials. (Photo: Craig Chandler | University Communication)

The body armor of beetles should typically weigh them down — imagine turtles and medieval knights. In reality, those hard shells protecting delicate wings are astonishingly light, even allowing flight.

A good understanding of the structure and properties of beetle exoskeletons could help researchers create lighter, stronger materials. These types of materials could, for instance, decrease gas-consuming drag in airplanes and vehicles and minimize the weight of armor, lightening the load for the modern day knight.

But demonstrating exoskeleton architecture at the nanoscale has proven challenging. Nebraska's Ruiguo Yang, assistant professor of mechanical and materials engineering, and his colleagues discovered a way to study the fibrous nanostructure. Their findings have been recently featured on the cover of Advanced Functional Materials.

The lightweight exoskeleton is made up of chitin fibers just about 20 nm in diameter (a human hair measures about 75,000 nm in diameter) and packed and arranged into layers that coil in a spiral, like a spiral staircase. The small diameter and helical twisting, called Bouligand, make the structure hard to examine.

Yang and his team developed a technique of slicing down the spiral to expose a surface of cross-sections of fibers at varying orientations. From that perspective, the researchers were able to examine the fibers' mechanical properties using an atomic force microscope.

This type of microscope applies minuscule force to a test sample, deforms the sample, and monitors the response of the sample. By integrating the experimental procedure and theoretical analysis, the team was able to expose the exoskeleton’s nanoscale architecture and the material properties of the nanofibers.

These discoveries were made in the common figeater beetle, Cotinis mutabilis, a metallic green native of the western United States. However, the method can be applied on other beetles and hard-shelled insects and might also extend to synthetic materials having fibrous structures, Yang said.

Going forward, evolutionary perception as well as a better understanding of the connection between structural features and their properties is possible by comparing beetles with varying demands on their exoskeletons, such as environmental damage or defending against predators.

Yang’s co-authors are Alireza Zaheri and Horacio Espinosa of Northwestern University; Wei Gao of the University of Texas at San Antonio; and Cheryl Hayashi of the University of California, Riverside.

This research was funded by the Air Force Office of Scientific Research’s Multidisciplinary University Research Initiative.