Image Credits: Sierra Instruments

Image Credits: Sierra Instruments

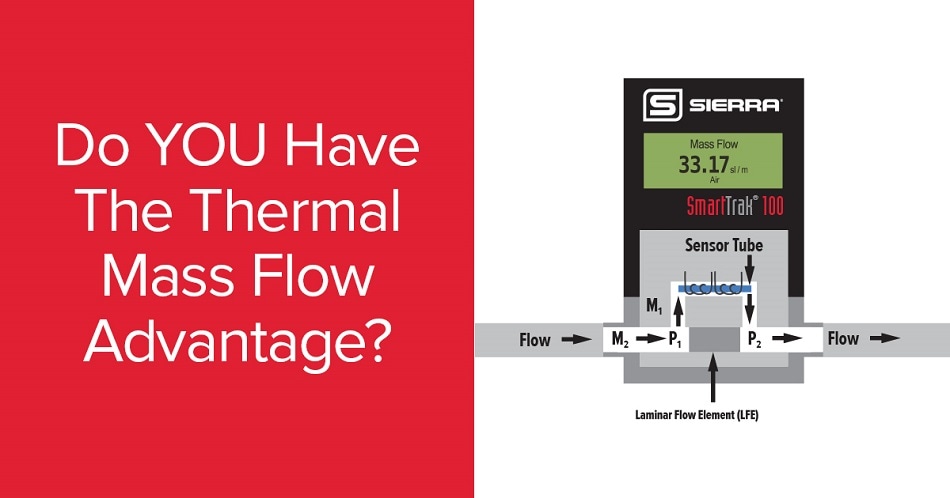

Direct Mass Flow Controllers Improve Accuracy for OEMs & Systems Integrators

Sierra Instruments announces the release of a new infographic explaining why mass flow controllers based on capillary thermal mass flow technology provide exponentially more accurate mass flow data than volumetric flow devices for industrial gas mass flow control applications. Over 80% of all industrial processes—such as those involving chemical reactions, combustion, respiration, pharmaceutical, and HVAC—require direct mass flow control and measurement of gasses, not volumetric flow rate, to ensure the quality and efficiency of their process.

Common process gases like air, argon, CO2, N2, oxygen follow the “Ideal Gas Law.” While not all gases are “ideal,” these common gases work on the principle that when temperature or pressure changes in an application, the density changes for a fixed volume of gas. Thermal mass flow controllers and meters, like Sierra’s SmartTrak, offer engineers direct gas mass flow measurement without pressure or temperature compensation using secondary inputs and a flow computer.

Volumetric flow, on the other hand, is less reliable than mass flow to account for absolute measurements because changes with temperature and pressure (T&P) affect the gas density, and thus reduce the accuracy of the flow measurement. Volumetric flow measurement also requires extra temperature and pressure compensation to “infer” true gas mass flow rate, which derates the accuracy and adds expense in extra equipment. In one compact mass flow controller, SmartTrak offers direct gas mass flow measurement and control that gives OEMs, researchers, and systems integrators increased accuracy, application flexibility, superior product quality, and ultimately more profit to the bottom line.

SmartTrak flow meters and mass flow controllers are CE approved; available in any flow range you specify from low flows (0 to 0.1 sccm) to high flows (to 1000 slpm), including a small footprint at 50 slpm (ideal for OEMs); and have a full suite of digital communication on board for easy process integration. SmartTrak also offers:

A wide operating range for temperature and pressure with high-pressure options (up to 5000 psig) and the best ultra-low pressure drop in the industry. For example: ΔP 4.5 psid (310 mBard) at 500 slpm, and ΔP 3.8 psid (258 mBard) at 10 slpm.

A strong and flexible control valve with accessible PID valve tuning to assure best control and reliability. Custom valve orifice sizing yields full-range stability.

The ability to choose from multiple gases on board or have engineers create a custom list of any gas—including corrosive, toxic and reactive gases.

NIST-traceable accuracy backed by our 10-point, primary standard calibration over the entire flow range.

For more information on the differences between volumetric and mass flow technology for industrial applications, download the new infographic today.