Jun 6 2017

A team of Researchers at the University of Illinois are working towards developing more environmentally friendly catalysts for the manufacture of resin and plastic precursors that are regularly derived from fossil fuels.

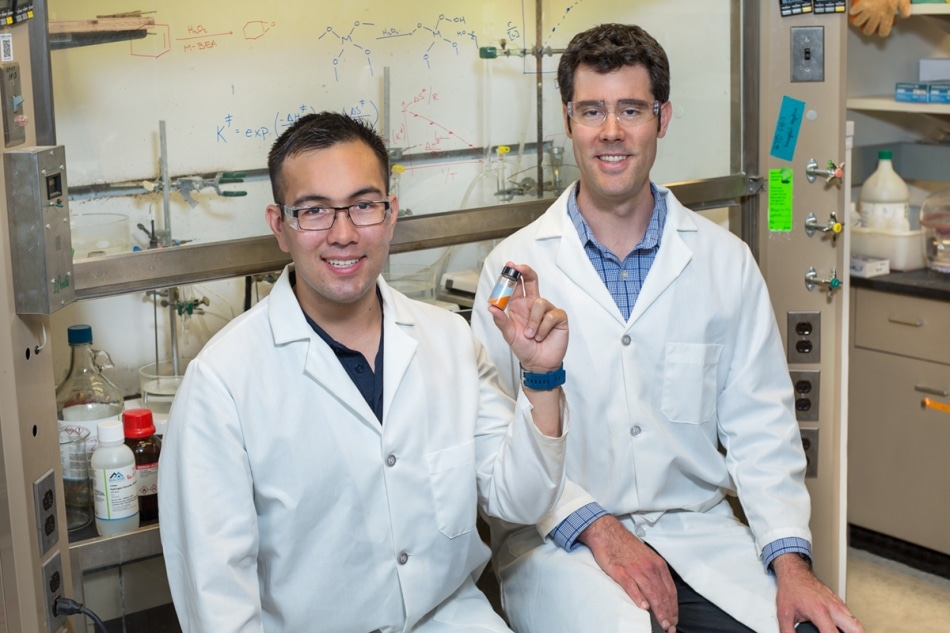

Illinois Professor David Flaherty, right, and Graduate Student Daniel Bregante are working on a greener way to produce plastic and resin precursors that are derived from fossil fuels, a process that might ultimately lead to broader industry adoption of this fine-tuned and environmentally conscious version of a much older process. (Photo by Joyce Seay-Knoblauch)

Illinois Professor David Flaherty, right, and Graduate Student Daniel Bregante are working on a greener way to produce plastic and resin precursors that are derived from fossil fuels, a process that might ultimately lead to broader industry adoption of this fine-tuned and environmentally conscious version of a much older process. (Photo by Joyce Seay-Knoblauch)

The key to their method arises from recognizing the unique chemical and physical properties of specific metals and the way in which they react with hydrogen peroxide.

A number of plastics are made from molecules known as olefins that are obtained from organic materials such as fossil fuels. To create these types of plastics, olefin molecules must be modified using oxidizing chemicals to make resin and plastic precursors, called monomers, by rearranging their chemical bonds so that they can reach out and clutch on to other monomers. This allows them to stitch together to form long molecular chains, which are the building blocks of plastics, said David Flaherty, a Professor of Chemical and Biomedical Engineering.

The current methods used for turning olefin molecules into something useful also uses or produces things we don’t want, like chlorine, which can be corrosive, and CO2.

Daniel Bregante, a Chemical and Biomedical Engineering Graduate Student and a Co-Author of a report on the new technique

Frequently, CO2 is thought of as a waste product of fossil fuel combustion. However, Flaherty said a substantial quantity of CO2 forms from the manufacture of plastics derived from fossil fuels.

Many manufacturing processes use environmentally toxic organic peroxide or chlorinated oxidants, Bregante said. Together, these concerns have driven the Researchers to search greener options for plastics manufacturing.

The Research team explored how and why the identity of certain metals, known as transition metals, influences the reaction. They also investigated how efficient the process is when using hydrogen peroxide – an environmentally friendly oxidant whose only waste product is water, not CO2 or chlorine. Their findings have been published in the Journal of the American Chemical Society.

To form the essential monomers, olefins and oxidizers pass via miniature, rigid sponge-like structures named zeolites. These zeolites comprise of metal ions in the pore spaces that serve as catalysts to drive the chemical reaction toward the plastic-producing pathway, Bregante said.

This process has been used for decades. Yet, the underlying reasons for how the metal atoms activate hydrogen peroxide and why some metals are better than others for this chemistry have not been fully understood.

David Flaherty, a Professor of Chemical and Biomedical Engineering

Flaherty’s team said their reaction can proceed in two pathways: one that paves way to the formation of monomers and one that leads to the inefficient decomposition of hydrogen peroxide. They have established in their most recent research that the two pathways will react differently based on which metal is used, and the subsequent step will be to understand how changing the pore size of the zeolites will influence the reactions.

By unraveling more of the mysteries of this reaction, Flaherty and Bregante said their research might eventually open the door to wider industry adoption of this tweaked and environmentally conscious version of a much older process.

We need to know not only that it works, but also how it works to convince industry to make the switch. The facilities used to produce plastics are starting to reach the end of their useful lifetime, and new industrial infrastructure based on this revised method could be a fresh start.

David Flaherty, a Professor of Chemical and Biomedical Engineering

This research was supported by the United States Department of Defense.