Jun 8 2017

North Carolina State University Researchers have used the principles behind the formation of sandcastles from wet sand in order to achieve 3D printing of porous and flexible silicone rubber structures via a new technique capable of blending water with liquid and solid forms of silicone into a pasty ink that can be sent through a 3D printer. The finding could have applications in soft robotics and also in the biomedical field.

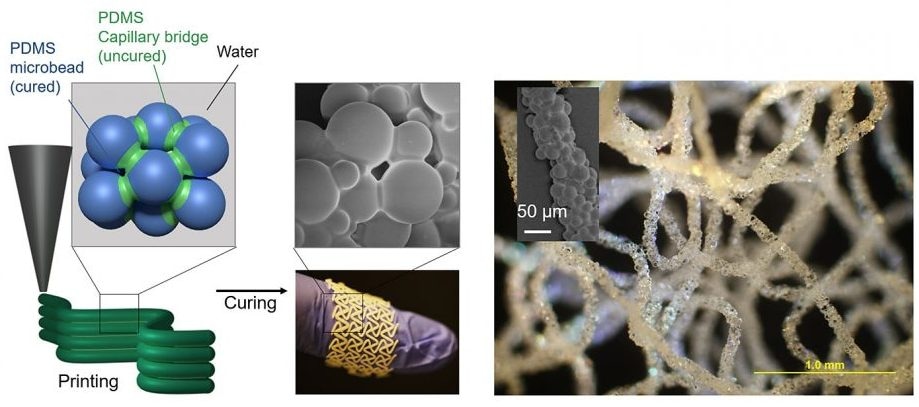

New technique published in Advanced Materials shows the process of 3-D printing silicone rubber. Credit: North Carolina State University

New technique published in Advanced Materials shows the process of 3-D printing silicone rubber. Credit: North Carolina State University

In a paper recently published in Advanced Materials, corresponding Author Orlin Velev and colleagues demonstrate that, in a water medium, it is possible to use liquid silicone rubber to form bridges between small silicone rubber beads in order to link them together – much as a minimal amount of water can help in shaping sand particles into sandcastles.

It is interesting to note that this technique can be employed in a wet or dry environment, highlighting that it is capable of being used in live tissue, for example, imagine an ultraflexible mesh encapsulating a healing droplet, or a soft bandage that has the potential to be applied or even directly printed on a particular part of the human body.

There is great interest in 3-D printing of silicone rubber, or PDMS, which has a number of useful properties. The challenge is that you generally need to rapidly heat the material or use special chemistry to cure it, which can be technically complex. Our method uses an extremely simple extrudable material that can be placed in a 3-D printer to directly prototype porous, flexible structures – even under water. And it is all accomplished with a multiphasic system of just two materials – no special chemistry or expensive machinery is necessary. The ‘trick’ is that both the beads and the liquid that binds them are silicone, and thus make a very cohesive, stretchable and bendable material after shaping and curing.

Orlin Velev, INVISTA Professor of Chemical and Biomolecular Engineering at North Carolina State University

The paper is co-authored by first Author Sangchul Roh, an NC State Ph.D. Candidate; NC State Graduate Student Dishit Parekh; Bhuvnesh Bharti, a faculty member at Louisiana State University and Dr. Simeon Stoyanov of Wageningen University in The Netherlands.

The National Science Foundation under grant CBET-1604116 and the Research Triangle Materials Research Science and Engineering Center on Programmable Soft Matter under grant DMR-1121107 funded this research. A provisional patent on the new technique has been filed by NC State.