Jul 18 2017

Imaging low-density materials such as tissues located between bones by using X-rays is very difficult. This is due to the fact that X-rays pass straight through the material similar to sunlight passing through a window. But what if you need to see the area that isn't bone?

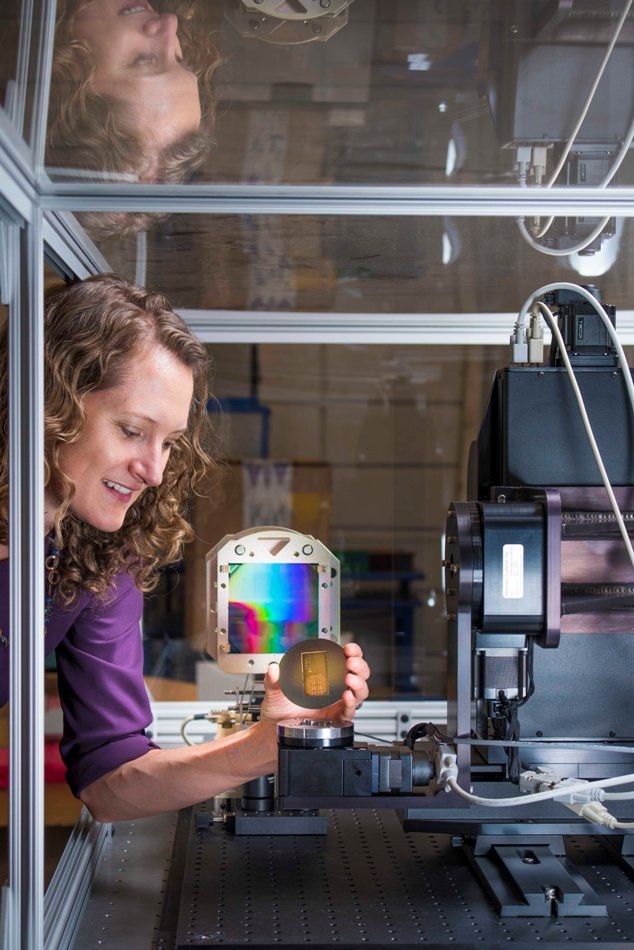

Sandia National Laboratories researcher Amber Dagel holds a calibration sample to be loaded into the labs’ X-ray phase contrast imaging machine. Dagel is principal investigator for the labs’ work into using X-ray phase contrast imaging to study low-density materials. CREDIT: Randy Montoya.

Sandia National Laboratories researcher Amber Dagel holds a calibration sample to be loaded into the labs’ X-ray phase contrast imaging machine. Dagel is principal investigator for the labs’ work into using X-ray phase contrast imaging to study low-density materials. CREDIT: Randy Montoya.

Research on a range of low-density materials such as laminate layers used in airplane wings as well as epoxies and foams used as cushioning for parts is carried out at Sandia National Laboratories. Hence Sandia borrowed and enhanced X-ray phase contrast imaging, a technology under research in the medical field, to get a better view of the softer side of things without the need for dismantling them.

Sandia must be in a position to detect flaws before they can lead to failures of higher consequence because materials that have cracks or voids do not have a high performance as they tend to get separated from adjacent surfaces. For instance, flaws such as grafoil in the laminate layers of the wing of an airplane cannot be observed using traditional X-rays if the protective copper mesh that diffuses energy is not removed at the time of lightning strike. Also, crucially significant foams and other materials that prevent thermal stresses, shock and high voltage breakdown in nuclear weapon components can also not be observed using traditional X-rays.

In contrast to traditional X-ray imaging, in which only the number of X-ray photons passing through the sample are measured, X-ray phase contrast imaging, in addition, has the ability to measure the phase of the X-rays after they enter the sample, thus enabling a thorough view of the interfaces in a structure.

For low-density materials like plastics, polymers, foams and other encapsulants, this phase signal can be a thousand times bigger than the absorption signal (of conventional X-ray).

Amber Dagel, Principal Investigator

Apart from being applied to investigate integrated circuits, microfabrication packaging and micro-electro-mechanical components, X-ray phase contrast imaging can also be applied to examine chemicals, ceramics, explosives or polymers.

The technology adopted by Sandia enabled accomplishing X-ray phase contrast imaging in a laboratory without using a synchrotron, which is very costly and also very huge.

More sensitive technique needed

Alternative prevalent methods are not adequately sensitive to differentiate between materials.

You have a dense material mixed in with a low-density material, and traditional X-rays can’t see that low-density material. So they don’t know if the gaps are filled with the low-density materials or if that’s air.

Amber Dagel, Principal Investigator

Consider the example of an orange, which Dagel had in her office. Knowing the fact that it is actually made of only low-density materials, she and her team imaged it to validate their system.

A traditional X-ray image of an orange is fuzzy and lacks any detail. In contrast, X-ray phase contrast imaging distinctively displays the dissimilarities between the thinner pith and zest layers and also their appearance as against the thick pulp.

When light hits the zest, it bends a little. It hits the pith and it bends a little bit more, then it goes through the pulp, and it bends another direction. Every interface, every time the material changes within the sample, it bends the light a little bit. Different parts of your sample bend the light differently, and measuring that is what gives rise to the phase contrast image.

Amber Dagel, Principal Investigator

Sandia’s study started with a Laboratory Directed Research and Development (LDRD) project between 2014 and 2016 which showed that X-ray phase contrast imaging can decipher the attributes of the connection between two materials. A fresh LDRD project related to the production of gratings that can function at higher X-ray energies will add to this technique.

Gratings (i.e. optical components resembling clusters of upright parallel bars) function like an interferometer and generate interference in the X-ray beam, thus integrating light sources to produce a measurable interference pattern.

Gratings are highly important in the success of the technology, and applying gratings at higher energies, “will let us look at more samples, samples that are denser or samples that are bigger,” stated Dagel. According to Dagel, although gratings are difficult to produce, Sandia’s metal micromachining team headed by Christian Arrington produces exceptionally uniform square gratings measuring nearly 4 inches. She further stated that this is deemed to be extensive, and Sandia has the ability to produce gratings as a single large piece with optimum uniformity. The portion of a sample that can be observed at once is determined by the grating size.

Many of the other research teams analyzing phase contrast X-ray imaging are investigating its use in medical imaging. On the contrary, Sandia is looking to use it for materials science applications.

Gratings make Sandia system possible

“By sampling the bright and dark pattern we’re able to reconstruct on the detector what this pattern must have looked like,” stated Dagel. “That’s if the light just goes through with no sample there. What if now I put something, like an orange, in front of it?” When the light wave passes through the orange, it is further delayed, “so now you took that waviness and you gave it even more shape. We’re measuring how this wave front, this phase, changes as it passes through the sample.”

Dagel considers that the technology will ultimately be largely effective not only for research but also for quality control in factories.

“I think it can be useful in the research phase, when you’re trying to understand the distribution of microbeads within an epoxy or how the foam is mating with the canister it’s filling up, is there a gap there? Or what defects can I see in my airplane wing laminate?” stated Dagel. “I also think it can be used in quality assurance: I know what my part should look like, but I need to make sure there aren’t cracks, there aren’t voids.”

The study has been presented by Dagel and her team at various conferences, among which are the International Workshop on X-ray and Neutron Phase Imaging with Gratings in 2015 and the SPIE Defense + Commercial Sensing conference last year.