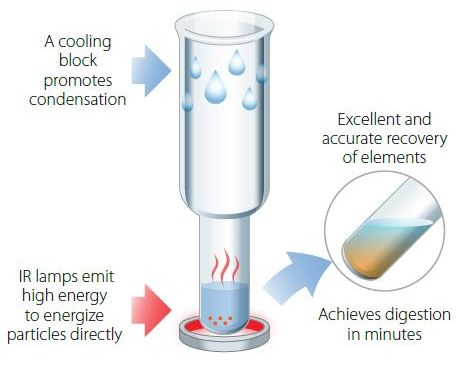

ColdBlock™ digestion involves dissolving solid matter into solution, in order to enable multi-element analysis. It is the first sample digestion technology to use focused, shortwave infrared radiation (FSWIR) for energizing sample particles.

A cooling zone is essential in encouraging a condensation effect that minimizes vapor escape, as these are created by this process of rapid heating and digestion.

Accurate and Precise Measurements*

| Geological Sample |

Average

% Recovery |

Average

% RSD |

| Gold (30 g Sample) |

100% |

2.4% |

Base Metals (Aqua Regia)

Base Metals (High Boiling Acid) |

99.6%

99% |

1.2%

1.2% |

Rare Earth Elements (CRM-1)

Rare Earth Elements (CRM-2) |

100%

107% |

1.7%

2.1% |

| Contaminated Soil Sewage Sludge |

97.5%

97.0% |

1.9%

2.1% |

Accurate Recovery of Gold

Substantial Cost Savings

A Solution for Substainability

Amira Global Project P1196

This particular project was undertaken in partnership with AMIRA Global and several industry sponsors. It was designed to evaluate traditional methods and compare these with ColdBlock™, exploring its use in analyzing geological materials of interest to the mining industry.

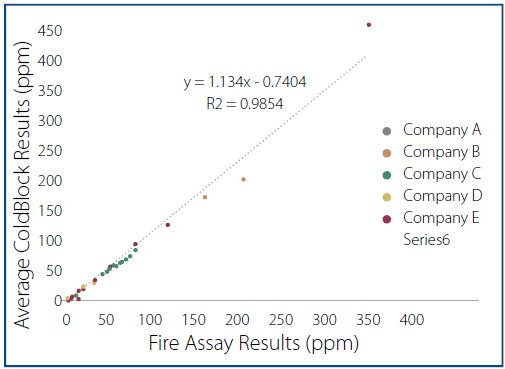

Phase 1 of the project involved digestion of specific gold ore samples, including company sponsor samples and certified reference materials, from each individual sponsor. This was done using both PbO Fire Assay and ColdBlock™ technology before their recoveries were compared.

Phase 1 revealed strong correlations in gold results between the traditional fire assay approach and the ColdBlock™ technology. R2 values ranged from 0.9045 to 1.000 for all of the five sponsors’ samples.

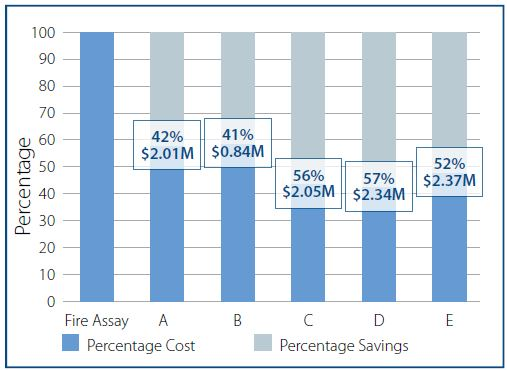

Return on investment analysis was carried out for the gold samples and highlighted a strong business case for employing ColdBlock™ technologies.

Using ColdBlock™ technology as an alternative to PbO Fire Assay saw the return on investment being recognized between day 1 and day 240, offering $0.84M to $2.4M USD savings over a five year period.

Capital Costs

- Required accessories

- Digestion equipment

- Analytical infrastructure

Operational Costs

- Waste disposal

- Consumables

- Labor costs

- Maintenance

- Power consumption

*http://www.coldblock.ca/resources/

This information has been sourced, reviewed and adapted from materials provided by ColdBlock Technologies Inc.

For more information on this source, please visit ColdBlock Technologies Inc.