ColdBlock™ Digestion (CBD) is a unique sample digestion technology which can dissolve geological rock samples into solution, enabling effective multi-element analysis. A project was recently undertaken with AMIRA Global to investigate and validate the use of ColdBlock™ in a ‘real world’ application setting.

AMIRA Global proved to be an ideal partner for this project, as the company regularly coordinates and delivers a wide range of collaboration-based solutions. AMIRA Global’s role was to help bring the ColdBlock™ technology to industry leaders.

A two-phase project was rolled out, which aimed to prepare for a future ‘rock-to-analysis’ solution, designed for onsite projects. This particular project used a combination of the 24-Channel Gold Workstation and the 30-Channel Base Metal System.

Five industry sponsors were involved; these were: Newcrest, Freeport McMoran, Newgold, SGS, and Centerra Gold. Queens University was also on board as an academic partner.

Project Goal

Properly validating the use of the 24-Channel ColdBlock™ CB24L Workstation for gold, while simultaneously validating the 30-Channel ColdBlock™ CB30S Workstation for base metals.

The following testing parameters were employed:

- Speed

- Safety

- Ease of use

- Accuracy and reproducibility

- ROI

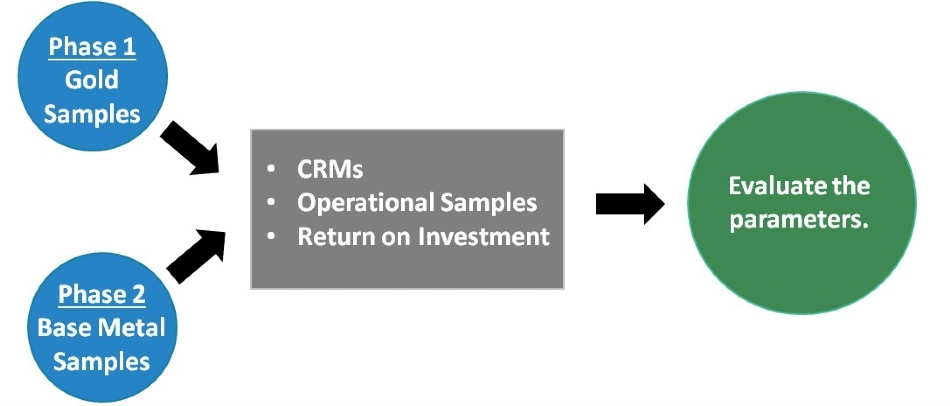

The first of the project’s two phases focused on gold samples while the second phase focused on base metal samples. Relevant certified reference materials were tested, alongside operational samples.

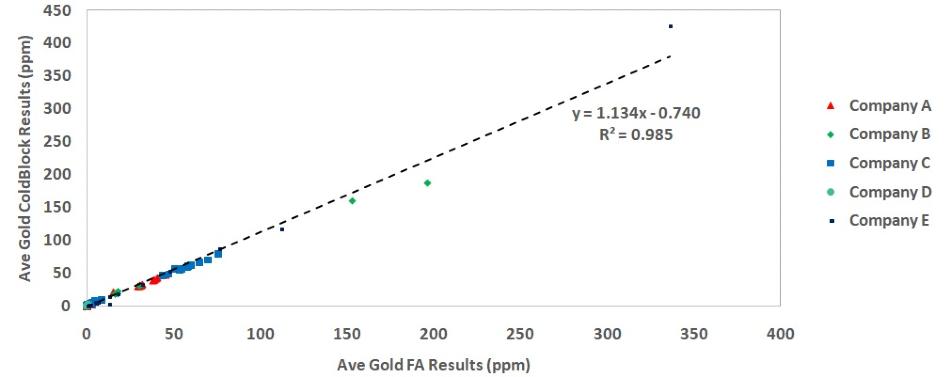

Selected gold samples included concentrates, feed and tailings from five different sponsors. The results showed a comparison of fire assay and ColdBlock™ digestions, which were done via aqua regia or reverse aqua regia, depending on the sample’s sulfur content.

Gold samples tested differed between each company, as well as within the samples tested by each individual company. This approach ensured that a diverse array of gold concentration samples were tested. Each individual sample was run in triplicate, with the average of each sample plotted.

The results revealed a strong correlation of 0.985 between fire assay and the ColdBlock™ digestion results.

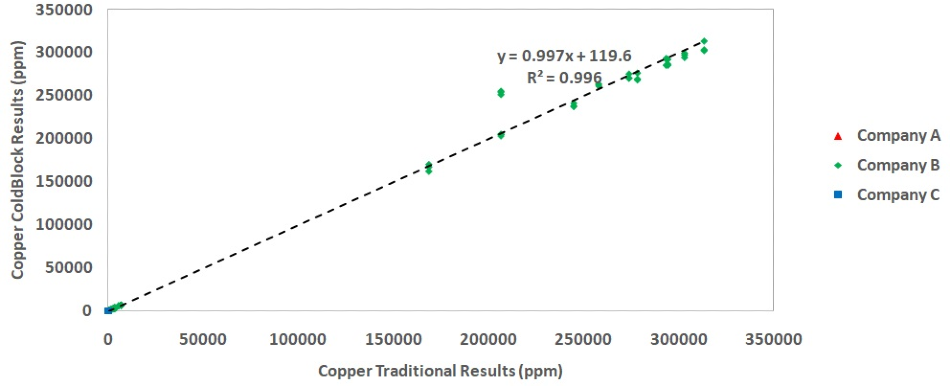

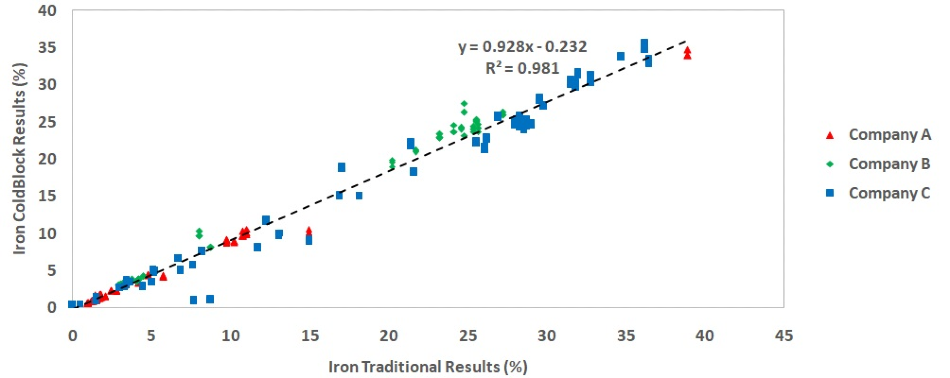

Base metal samples selected included concentrates, feed and tailings from three different sponsors. Each of these base metal samples was analyzed for iron and copper.

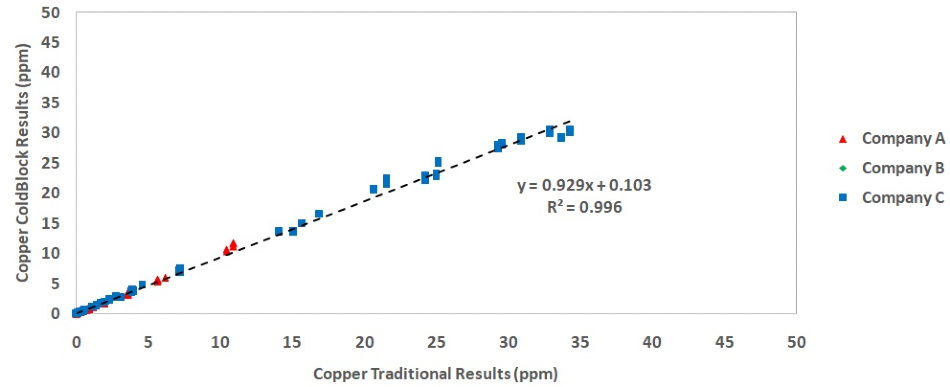

For the copper analyses, traditional digestions were contrasted with ColdBlock™ digestions. Aqua regia and reverse aqua regia were also used within the ColdBlock™ digestion method. Here, traditional digestion methods utilized two or three acid digestions, depending on the sponsor and the sample in question.

A strong correlation of 0.996 was observed between the traditional and ColdBlock™ digestions.

The figure above displays the copper results, expanded to better show the lower concentrations.

The iron results also revealed a good correlation of 0.982 between the two methods.

Return on Investment (ROI) analysis was undertaken by the participants.

Here, capital costs were based on the use of a 24-channel system for gold and 30-channel system for base metals. Costs were divided and structured into two distinct categories: capital costs and operational costs, before being extrapolated over a five year period. Additionally, the companies were blinded to ensure confidentially.

| ROI Cost Categories |

| Capital Costs |

Operational Costs |

- Digestion Equipment

- Required Accessories

- Analytical Infrastructure

|

- Consumables

- Maintenance

- Power Consumption

- Labour Costs

- Waste Disposal

|

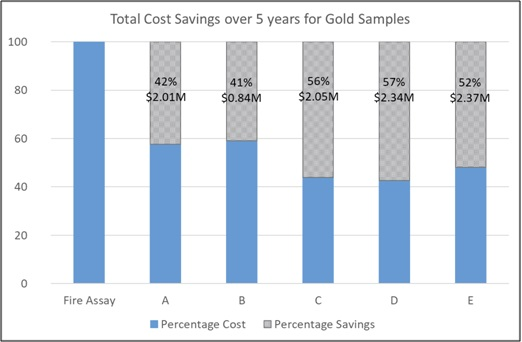

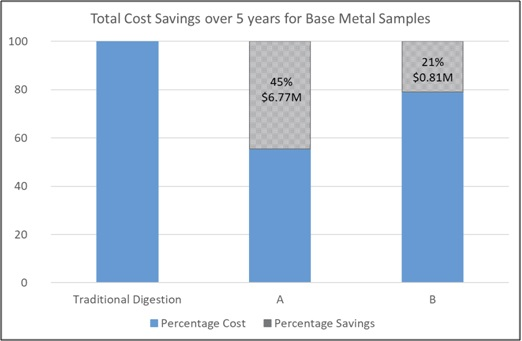

The ROI for both gold and base metal applications is shown in the following figures.

Gold Application 5 Year Savings

Base Metal Application 5 Year Savings

Cost savings for gold application were found to range from $840,000 to $2.37M USD, averaging $1.9M USD – or a 50 % reduction in costs - across the five companies. This calculation was based on the companies processing an average volume of 170 samples per day.

Cost savings for base metal applications were found to be $810,000 and $6.77M USD respectively for Company A and Company B. These differences are primarily a result of the difference in volumes of samples processed between each of the two companies.

A comparison between traditional methods and ColdBlock™ implied that both procedures would provide similar results for both gold and base metal.

The project was found to have validated both the 24-Channel Gold Workstation and the 30-Channel Base Metal System in terms of their accuracy and speed. Their reduced environmental impact and enhanced workplace safety were also validated due to their elimination of lead, HF and Perchloric Acid use.

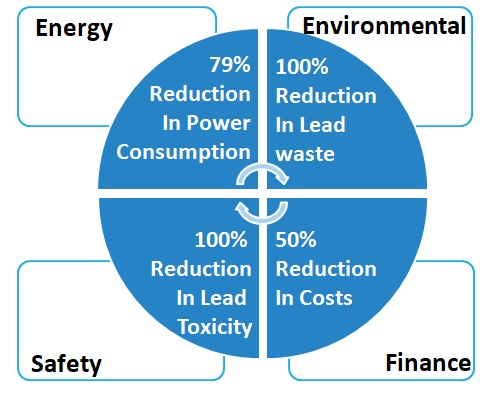

The project revealed that substantial an ROI over a five year period could be achieved, with results touching on Environmental, Energy, Safety and Finance.

Conclusions for Gold Application

This information has been sourced, reviewed and adapted from materials provided by ColdBlock Technologies Inc.

For more information on this source, please visit ColdBlock Technologies Inc.