Polymers exhibit a virtually unending array of physical properties, durability and appearances. This variety makes polymers the material of choice for applications in transportation, building materials, packaging, electronics and a range of other areas.

Image Credit: ATLAS Material Testing Technology

Degradation of Polymers

Polymers can undergo irreversible chemical and physical changes when exposed to ultraviolet (UV) radiation, heat and moisture. This is especially prevalent when polymers are used outdoors.

UV radiation can initiate photo-oxidation degradation pathways when in the presence of oxygen. Every polymer has a degree of spectral sensitivity, typically within the short-wavelength UV range, long-wavelength UV range and lower visible wavelength range.

Weather can cause a number of property changes, including:

- Yellowing - particularly of white or transparent polymers

- Color changes

- Reduced physical strength

- Development of microcracks in the surface that cause gloss loss

- Brittleness

- Color fading in dyed or pigmented polymers

UV Stabilization

A number of techniques are available to help protect polymers against photo-oxidative degradation due to the damaging effects of UV radiation.

Any company manufacturing masterbatches or processing polymers into components or products must ensure that the right type and quantity of stabilizer type is used in a formulation.

The most important tools for understanding the weatherability of these polymers are laboratory and natural weathering tests.

Selecting the Most Appropriate Test Method

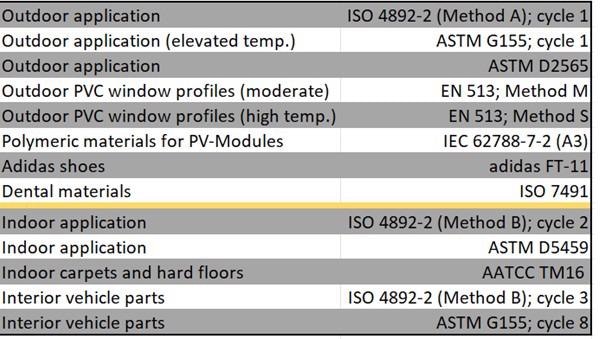

Source: ATLAS Material Testing Technology

The range of xenon-arc standardized test methods available for outdoor and indoor polymer applications has increased in recent years. The table below lists eight of the most commonly used outdoor and five of the most commonly used indoor test methods.

Most polymer manufacturers are concerned with selecting the right test method for their products.

This question can be answered more easily when a tailored standard has already been written for the product under development, for example, an appropriate standard for dental materials, PVC window profiles, hard floors, indoor carpets, or PV-module materials.

Products without an existing standard in place present more of a challenge. These applications are generally tested in line with generic weathering standards such as ASTM G155 cycle 1 and ISO 4892-2 Method A/B.

As defined test durations are not in place, it is important to determine the duration of laboratory tests and ensure that these are able to effectively reproduce the property changes caused by natural weathering.

Natural weathering benchmark studies are the most ideal and widely used solution to this issue.

This information has been sourced, reviewed and adapted from materials provided by Atlas Material Testing Technology LLC.

For more information on this source, please visit Atlas Material Testing Technology LLC.