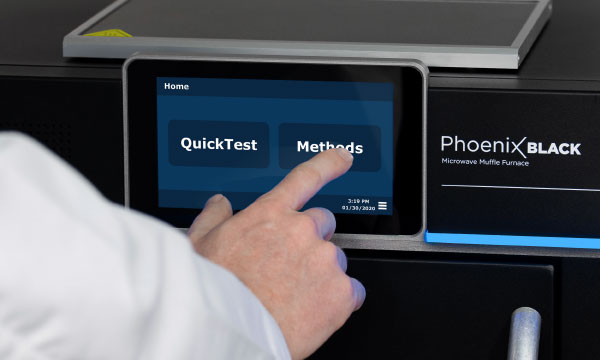

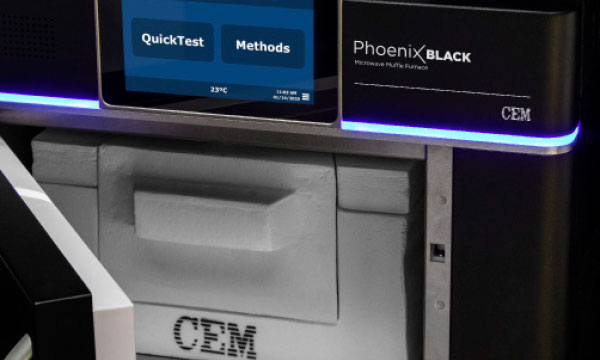

The Phoenix BLACK™ from CEM can be used to ash samples with unparalleled speed and safety. Featuring an integrated touch-screen interface, the Phoenix BLACK™ allows users to streamline their workflow and save time.

The cavity is heated by two strong magnetrons, enabling extremely fast ramp times and excellent temperature control. Users can make rapid changes to reduce out-of-specification products and enhance their process control.

Features

- Users can employ any kind of crucible generally utilized in traditional ashing systems and even platinum

- Ashing of up to 15 samples can be performed at the same time

- Meets the needs of microwave and electrical muffle furnaces

Fast

- Temperatures can be increased quickly

- Samples can be ashed up to 97% faster when compared to conventional muffle furnaces

- One-step ashing — integrated with complete pre-ash functions, the furnace removes the necessity for a Bunsen burner

- Users can go directly from the furnace to the balance without the desiccation step

Image Credit: CEM

Safe

- Quartz fiber crucibles cool down in just a few seconds

- Active ventilation maintains the laboratory free from odors and soot

- Built-in sensors hold the cavity door open while removing the furnace door

- NIST-traceable thermocouple guarantees precise temperature control

Image Credit: CEM

Easy to Use

- PQ/OQ/IQ service is available for audit traceability and turnkey validation

- User-friendly program techniques with automatic temperature ramps and start time

- Automated sulfated ashing — users can just place the samples in the furnace and press start

- Combined with printer and balance for automatic results — manual calculations are not required

Image Credit: CEM

Meets Industry Requirements for Muffle Furnaces

The Phoenix BLACK™ fulfills the requirements for techniques that specify “microwave heated” furnaces, as well as techniques that specify “electrically heated” furnaces.

Most Common Methods

- ASTM D5630-94—ash content of thermoplastics

- ASTM D874-92—sulfated ash content of lubricating oils

- IP 501—fuel oil sample prep by ashing

- USP 281—sulfated ash or Residue on Ignition (ROI)

- USP 733—Loss on Ignition (LOI)

- Numerous FDA, AOAC, DIN, and ISO techniques

- And more

Image Credit: CEM

Temperature calibration and temperature verification for GLP and ISO practices are easily and rapidly carried out with optional accessories, such as calibration source instruments and NIST-traceable dual thermocouples.

Removable Furnace Inserts

Users can easily swap out the furnace inserts to suit their requirements.

Image Credit: CEM

Image Credit: CEM

Image Credit: CEM

High Temperature Furnace Insert

- Has the capacity to hold up to 5 (100 mL) or 8 (20/50 mL) quartz fiber crucibles

- Heats up to 1200 °C

High Capacity Furnace Insert

- Has the capacity to hold up to 12 (100 mL) or 15 (20/50 mL) quartz fiber crucibles

- Heats up to 1000 °C

Quartz Fiber Crucibles

Image Credit: CEM

Faster

The design of the quartz fiber crucible enables air to spread inside the sample and reduces test times to just 15 minutes.

Safer

Crucibles cool down within seconds, therefore considerably decreasing the risk of burns when compared to ceramic crucibles.

Easier

The crucibles cool down almost immediately. They can be weighed instantly after ashing without the need for desiccation or long cooling times.

Microwave Muffle Furnace | Phoenix BLACK

Improving Process Control with the Phoenix