|

|

||||||||||

Electrical Discharge Machining and Surface Alloying – The Process, Parameters and State of Play |

||||||||||

Topics Covered |

||||||||||

|

What is Electrical Discharge Machining? How Does Electrical Discharge Machining Work? Surface Alloying During Electrical Discharge Machining Problems Associated with Surface Alloying Producing Wear and Corrosion Resistant Surfaces The Effect of Open Circuit Voltage Hardness Increase Due to Surface Alloying Surface Alloying of Titanium Alloys |

||||||||||

Background |

||||||||||

|

The past

five years have seen an increasing interest in the novel applications of

electrical discharge machining, particularly from the Far East and Europe,

with industry starting to see the potential of the technique for surface

modification. Normally used for manufacturing dies/moulds and aerospace

components, researchers at the University of Birmingham are adapting the

technique to enable surface hardening of workpieces to create, in some cases,

new, harder alloys on the surface of components to increase their working

life and wear resistance. What is Electrical Discharge Machining?

Electrical

discharge machining (EDM) is a thermal process that involves melting and

vaporisation of the workpiece electrode. It is widely used in the aerospace,

mouldmaking and die casting industries for manufacturing plastics moulds,

forging dies and die casting dies made from hardened tool steels, together

with engine components, such as compressor blades made from titanium alloys

and nickel-based superalloys. In addition to the more well known EDM

operations of die sinking, scanning/milling with a simple electrode and wire

cutting, other operations and machine configurations exist, one of which

allows the surface of hardened steel rolls used in the production of steel

and aluminium sheet to be textured. How Does Electrical

Discharge Machining Work?

The EDM

process uses electrical discharges to remove material from the workpiece,

with each spark producing a temperature of between 10,000-20,000°C.

Consequently, the workpiece is subjected to a heat affected zone (HAZ) the

top layer of which comprises recast material. The thickness, composition and

condition of this layer depend on the discharge energy and the make-up of the

workpiece, tool electrode and dielectric fluid, and both hard and soft

surface layers can be produced despite perceived wisdom that the recast layer

is always hard. With ferrous workpiece materials, the recast layer typically

appears white and amorphous when viewed under a microscope, and is prone to

tensile stress, microcracking and porosity. The Recast Surface Layer

To increase

the life of the tool or product, the recast layer is generally removed,

particularly for applications in which the part is subjected to cyclical

stress (aeroengine components) or fluctuating loads (forging and punching

tools/dies). This is achieved either by hand polishing, etching or heat

treatment. Alternatively, burnishing or shot peening is employed in order to

impose a compressive residual stress regime. However, such processes are

supplementary and may increase cost and time. With operations in which

repeated high levels of mechanical impact are not a factor, such as plastics

injection moulding, the EDM recast layer can be beneficial in providing

increased abrasion and corrosion resistance. Surface Alloying During

Electrical Discharge Machining

Another

way of improving the surface integrity and wear resistance of an EDM

workpiece is by applying surface alloying during sparking, using either

partially sintered powder metallurgy (PM) tool electrodes, or by dispersing

metallic powders in the dielectric. Several published papers detail the use

of powders suspended in the dielectric as a means of producing surface

alloying. This is an extension of work where powders, typically graphite,

aluminium (Al) or silicon (Si), varying in size from 1-100 µm, are used to

produce mirror-like EDM surfaces with minimal microcracking. Although

deionised water can been used, the majority of current work uses hydrocarbon

oil dielectrics (kerosene/paraffin), which produce carbides through

carburisation with pyrolytic carbon. Problems Associated with

Surface Alloying

This

approach is not without its problems despite the potential to increase

workpiece hardness from 2-6.5 times that of the bulk material and produce

recast layers of 10-150 µm thick. It is difficult to achieve a uniform

distribution of the powder in suspension and filtration of the dielectric can

be counter-productive. Electrode Materials

Very

little surface alloying occurs when using ‘conventional’ tool electrodes

under standard polarity compared to partially sintered PM electrodes, where

the binding energy between grains is considerably lower. Negative tool

polarity is usually employed and PM electrode materials used include Al, Cr,

Cr/Ni, Cu/Co, Cu/Mn, Cu/Sn, Cu/W, Ni, Ni/Co, Ni/Fe, Ni/Mn, Ni/Si, Ti, Ti/A1, TiC/Ni,

W/CrC/Cu and WC/Co. Figure 1 shows a schematic of the process. This approach

to surface alloying is relatively new and there is little information on

aspects such as preferred particle size, sintering temperatures and

pressures. However, powder sizes of less then 50 µm are quoted with

temperatures of ~900-1300°C and pressures of ~100-550 MPa.

Producing Wear and

Corrosion Resistant Surfaces

Current

research at Birmingham involves the use of WC/Co and W/CrC/Cu partially

sintered hardmetal tool electrodes for EDM surface alloying, together with

non-standard wire materials to produce wear and corrosion resistant surfaces.

One of the challenges of the research is to produce surfaces that are highly

alloyed and have high wear resistance, but meet the surface roughness and

topography requirements of the mouldmaking, die casting, rolling and

aerospace industries. The effect of electrical parameters such as peak

current, open circuit voltage, polarity, pulse on/off times and capacitance

on recast layer thickness, and workpiece microstructure, microhardness and

composition, are being evaluated. Much of

the equipment being used is commercially available, with PM products

manufactured by Vacuum Impregnated Products and standard hydrocarbon oil

(paraffin) dielectric being used. However, in order to increase electrode

wear (contrary to common practise where minimum wear is desirable) and

achieve greater surface alloying, generators with higher than normal open

circuit voltage - up to 300 V - are being used. The Effect of Open

Circuit Voltage

Work on

tool and roll steels (AISI H13 hot work tool steel and 2% Cr steel) is being

sponsored by the Engineering and Physical Sciences Research Council (EPSRC)

in collaboration with Alcan, Charmilles, Dynacast, Erodex, The Gauge and

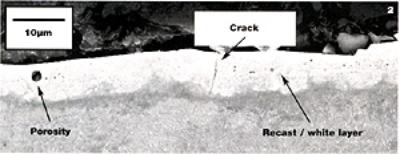

Toolmaker’s Association (GTMA) and SparkTec International. Figure 2 gives a

sample workpiece microstructure when die sinking AISI H13 heat treated to

600-640 HK0.025 using preferred operating parameter levels

identified in a Taguchi fractional factorial experiment. Analysis of the

machined surface revealed a 5-20 µm thick recast layer with some evidence of

cracking and porosity Figure 3a shows the corresponding microhardness depth

profile, while figure 3b illustrates the microhardness results from a test

where all the parameters were the same except a lower open circuit voltage

(125 V) was used. By comparison, the higher voltage caused microhardness at a

depth of 5 µm to increase from 1,116 to 1,319 HK0.025.

Production of Textured

Rolls

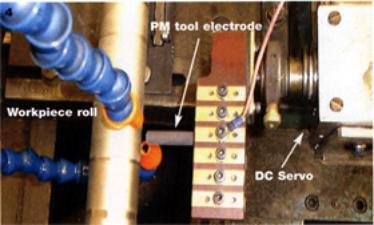

Surface

alloying is also being used to produce textured rolls, see figure 4. Here, a

PM tool electrode is used to scan along the axis of the rotating roll, while

simultaneously moving normal to its surface due to the action of the DC servo

system employed in order to maintain a constant spark gap. A number of

texture bands can be seen, corresponding to tests made with varying operating

parameter levels. The dielectric fluid, which normally floods the spark gap,

has been switched off. Typically, the surface textures produced using the PM

tool electrodes were very similar to the results obtained with conventional

Cu/graphite and graphite electrodes. The Ra and peak count (Pc) values of the

different texture bands were in the range of 2.1-2.4 gm and 113-121 peaks/cm,

respectively. These values conform to the requirements needed to roll

aluminium strip in the automotive industry.

Hardness Increase Due to

Surface Alloying

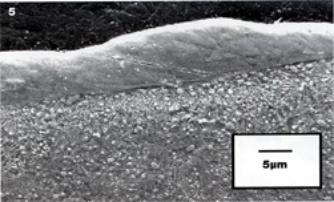

A SEM of

a typical roll cross section is given in figure 5, which shows a fairly

uniform recast layer with a thickness of ~10 gm and a surface microhardness

of 930 HK0.025 compared to 800-880 HK0.025 for the bulk

material. On the face of it, this increase does not appear impressive.

However, when texturing the rolls using conventional electrodes, the typical

hardness is only 540 HK0.025 The roll was textured with a

partially sintered (1000°C) WC/Co PM electrode and the corresponding X-ray

diffraction (XRD) plot shows the presence of complex carbides in the recast

layer. Currently, such surfaces are being evaluated using scratch and

bi-directional wear tests in order to assess their performance when compared

with textured surfaces employing a hard chromium plated layer.

Surface Alloying of

Titanium Alloys

Universities

UK, Rolls-Royce and Erodex are also supporting a parallel project on

aerospace titanium alloys (Ti6Al4V and gamma TiAl). When EDM scanning Ti6Al4V

using fully sintered WC/Co electrodes, 10-25 µm thick recast layers with high

porosity have been observed. These contained cracks, which increased in

density with negative tool polarity However, they did not penetrate into the

bulk material. Surface microhardness values were extremely high, ranging from

600-2900 HK0.025 compared with 360 HK0.025 for the bulk

material. Combining Powder and

Powder Metallurgy Electrodes

The

application of powders and PM electrodes are not mutually exclusive and their

simultaneous use offers the prospect for harder, more wear resistant surfaces

with low roughness and minimal cracking. In general, the use of PM tool

electrodes allows higher discharge energies than surface alloying with

suspended powders, producing thicker recast layers (10-100 µm) and increased

workpiece surface microhardness. Summary

EDM

surface alloying has the potential to open up new horizons but its take up in

industry has been slow owing to the commercial availability of PM electrodes

and the associated EDM technology. For example, current generator

specifications (especially with regard to high open circuit voltage) are

generally designed to minimise electrode wear and workpiece recast layers.

This aspect will shortly be explored further at Birmingham with a new pulse

generator capable of accommodating ultra high frequency discharges (1000 kHz)

at up to 600 V. Work is also ongoing to evaluate the manufacture of PM

electrodes via laser fabrication, which would allow the production of

multi-element products with in-built dielectric flushing channels. While falling outside the scope of the majority of EDM users, the surface alloying approach, whether using solid electrodes or novel wires, will undoubtedly become established, albeit for specific applications. |

||||||||||