As the valuable fibers of paper are guaranteed to be reclaimed for reuse when recycled, recycling, therefore, has higher priority over composting in the Circular Economy and the Sustainability Pyramid.

Paper fibers can be recycled up to 25 times, depending on end-use and type of fiber, but fiber degradation is still a concern as fibers tend to become shorter and weaker after multiple rounds of recycling.

Due to this issue, fibers are sorted prior to processing. Waste and screened-out fiber are able to be incinerated at end of life for energy recovery, such as being used to create combustion for steam and electrical energy production, resulting in carbon neutral emissions.

Composting only becomes a viable alternative to recycling when it is difficult to recycle, for example, if items are heavily contaminated with food. Composting should be regarded as an opportunity to divert food waste from landfills.

Image Credit: Michelman

The Effects of Polyolefin Films on the Recycling Process

Plastic films including polyethylene, polypropylene and polyester create many recycling issues for paper mills when laminated to paper. There is increased use of laminates, and it is difficult for mills to process the increased amount of film.

Film protects the fibers from water, causing it to take more time to repulp the paper and decreasing the capacity of a paper mill’s pulper.

The strong plastic film either gets beaten down into smaller flakes or sorted out using a specific drum-shaped pulper and bypass systems; this increases the energy needed to separate the filmic flakes from the fibers.

In either case, higher amounts of plastic films in the recycling mix results in higher costs for disposal, higher costs for separation and higher amounts of waste.

Laminated paper-plastic films are also difficult to recycle as plastic because paper fibers are difficult to extract from the film and will cause contamination in the plastic recycling process.

Replacing Plastic Film with Water-Based Barrier Coatings

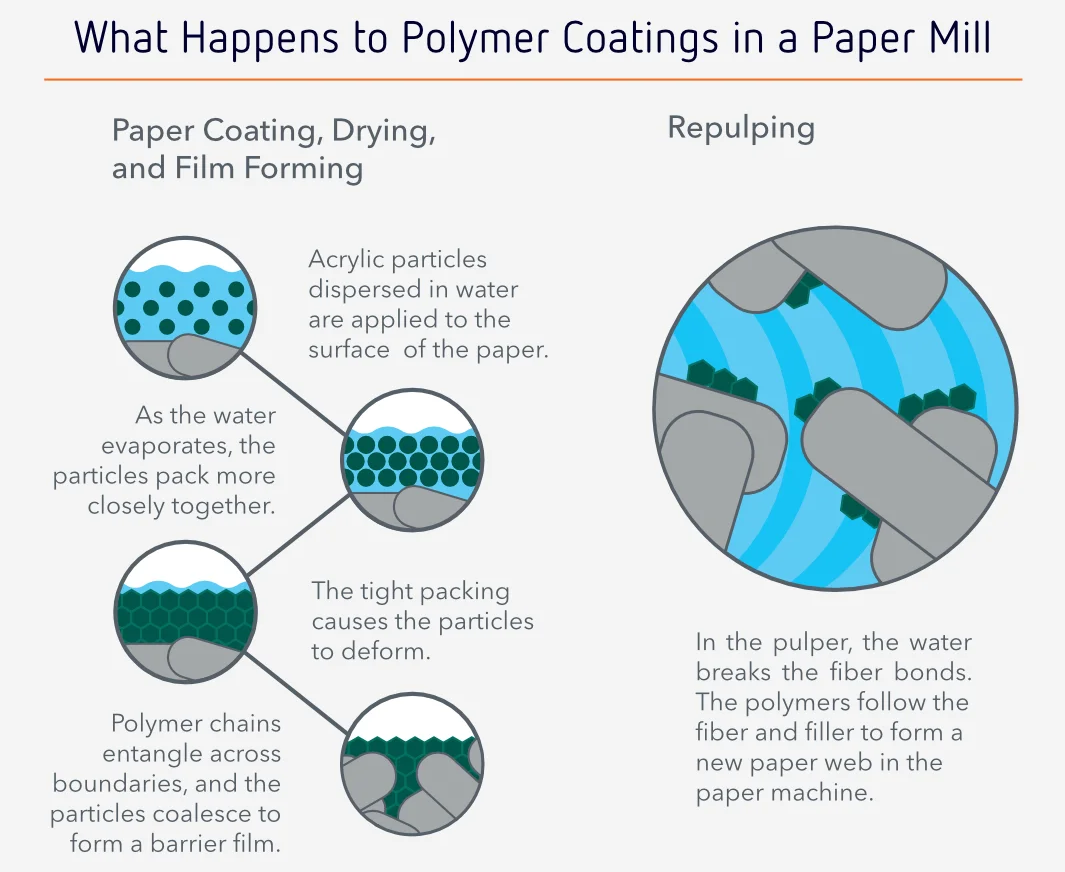

Polymeric coatings, which are water-dispersed emulsion polymer coatings, are often used as functional or barrier coatings on paper to replace the use of plastic film while giving paper specific functionality. These include heat sealing, oxygen, aroma, moisture or vapor barrier, water repellency or grease resistance.

The polymer material creates a continuous thin film that is not able to function as a main structural component of the final article because it lacks structural integrity on its own. It also does not add to the final product’s structural integrity.

These barrier coatings are water-based and behave similarly to the traditional binders that have been used in pigment-coated papers for decades. The water-based barrier coating particles will either stick to the fillers or fibers during repulping. They may also follow the appropriate fiber/filler recycle streams:

- Get washed with fillers, fiber-broke, water, etc. and then are sent to wastewater treatment plants for separation (sedimentation or flotation) (1-2% of the mass).

- Separate at a paper machine’s wet end, get de-watered during final cleaning stages and then sorted for material supply at street works, cement factors, etc. or incinerated (1-20% of the mass).

- Separate during stock preparation (via deinking, flotation, cleaners, washers, screens) for material supply for street works, cement factories, etc. or incinerated (1-20% of the mass).

- Used to form new paper sheets (80-99% of the mass).

The coatings are turned into sludge through physiochemical and/or biological (aerobic or anaerobic) treatments. The sludge is then either sent to landfill or incinerated. The sludge is pumped back into the middle layers of their board by some mills.

Barrier coatings that are used for heat seal at very low temperatures can be tacky and can when recycled, create “stickies,” or agglomerates of tacky substances, in the web forming and drying stages.

Limiting the amount of barrier coated papers added to the recycled paper mix (either by deinking cells or by separating it), using sticky control measures such as masking additives, and choosing the right barrier can control the formation of stickies.

Many polymer barriers are hydrophobic, meaning they attract inks during the recycling process; this can result in dirt spots. This means that if deinking is not part of the recycling process, it is better to reuse barrier-coated papers for the production of grades where color consistency is not important.

Conclusion

Functional water-based barrier coatings have the following advantages over paper-plastic film structures like PET, PP and PE, when using the standard paper waste stream:

- Only relatively small amounts of water-based barrier coatings are needed to reach sufficient and specific functionality, meaning they use resources more efficiently

- Less contamination, less plastic waster and easier processing to improve recyclability

Michelman is a member of the 4evergreen group at CEPI, a cross-industry alliance created to boost the contribution of fiber-based packaging for a sustainable and circular economy and society to minimize environmental and climate impact.

4evergreen’s goal is to use scientific facts to optimize collection and recycling systems, drive and support industry recognized guidelines for packaging and design, and the development of traceability and transparency of sustainable supply chains, as well as their accessibility and environmental credentials.

Oliver Kalmes. Image Credit: Michelman

This information has been sourced, reviewed and adapted from materials provided by Michelman Inc.

For more information on this source, please visit Michelman Inc.