The sensory experience of a cosmetic product is based on its appearance, texture, and odor, and is a measure of its quality.

Customer acceptance of cosmetic products is largely based on the physical characteristics of the product, mainly the way it feels to the touch. In the retail sector, where some cosmetic products are expensive, the physical characteristics of cosmetic products need to be combined with the expected performance based on the manufacturer’s claim.

Most cosmetic products are meant to be applied on the skin, and so their texture characteristics at application are as important as the subsequent feel. The main aim of chemists in the personal care, toiletries, and the cosmetic sector is to make sure that the entire range of colors and scent options consistently match the expected physical texture.

Figure 1. Different cosmetic products

Product Types

The different types of cosmetics are as follows:

Types of viscous semi-solid cosmetics (Figure 2) include sun-protection or tanning lotions, shampoos, moisturizers, lotions, gels and creams, shaving creams, liquid soaps, bath or shower gels and waxes, or other products that contain hydrocolloids, lipids, polyols, emulsions, and emollients. Although a certain degree of firmness is expected in these products, they should also be easy to spread and capable of flowing easily.

Figure 2. Semi-solid cosmetics

These skin creams are expected to have a smooth, creamy, and rich texture, and be light but not slippery or greasy. They need to be formulated such that they moisturize and hydrate, but do not produce oiliness on the skin despite the presence of oils.

Bar soaps, lip balms, solid block deodorants or antiperspirants, eye and lip liners in the form of pencils and lipsticks which are manufactured in the form of cohesive blocks are classified as solid cosmetics (Figure 3).

Figure 3. Solid cosmetics

Solid cosmetics are expected to deform and wear off over their use, but during the application, they are expected to remain hard and maintain their structure without flaking, breaking, or crumbling.

Cosmetic products in particulate form are termed compacted or loose powders (Figure 4). These products are dry and need to be applied with the help of sponges, brushes, and similar applicators. Eye shadow and make-up foundation in particular need to flow in a consistent and controlled manner, without caking or clumping.

Figure 4. Cosmetic powder palette and texture testing images

Test Methods for the Cosmetics Sector

The assessment techniques used for evaluating the characteristics of cosmetic products are similar to those followed in the food industry. For semi-solid, viscous products, their firmness, stickiness, consistency, and flow characteristics are evaluated, while the break resistance and hardness are evaluated for solid products. For powder cosmetics, clumping is checked by visual inspection to evaluate spread and flow characteristics.

The movement of fingers during the handling and application of these products is replicated using a suitably shaped probe. The way in which a product is extracted from its packaging is an important factor in the cosmetics industry. Extrusion methods are used to test this, with texture testing accessories being employed. Additionally, the effort required to pump or squeeze the product from its container is also evaluated.

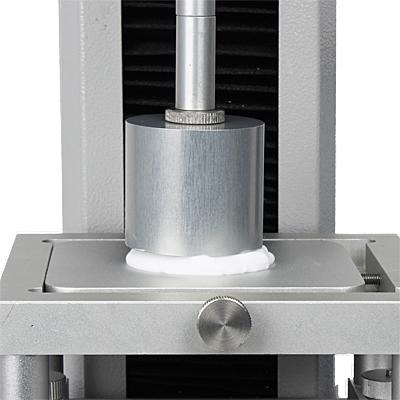

Compression

Textural properties such as cohesiveness, fracturability, and firmness are evaluated through compression testing using spherical or cylindrical probe fixtures. The runniness or firmness of moisturizers and the crush resistance of sculpted soap bars can be evaluated through compression testing.

Figure 5. Compression testing of a cosmetic product

Extrusion

Extrusion testing (Figure 6) is specifically used for testing semi-solids in isolation, with the help of extrusion fixtures. The interaction of semi-solid cosmetics with the dispenser and packaging can also be evaluated using forward or back extrusion methods.

Figure 6. Extrusion testing of a cosmetic product

Back extrusion is useful for testing the flow characteristics of bath creams, and the spreadability and ease of applying moisturizers, masks, pastes, and hair waxes. The dispensability of shampoos and creams can be evaluated by forwarding extrusion.

Penetration and Puncture

The strength of solid samples is tested by penetrating them with needles, cones, and small cylinders, while a ball probe can be used for evaluating the thickness and firmness of a semi-solid.

The cake strength and compaction of talc, eye shadows, and face powders can be evaluated by penetration and puncture testing (Picture 7). Some other characteristics that can be evaluated by this method include fracture strength and hardness of lipstick, soap and solid deodorants, crumbling resistance of liner pencils, and firmness of moisturizers.

Figure 7. Penetration and puncture testing on cosmetics

Shear, snap, bend and break

Evaluating the performance of cosmetic products that are subjected to stress during usage can be useful in assessing their formulation and the resulting texture. For instance, this can be used to review a lipstick bullet that is subject to bending during application (Figure 8).

Figure 8. Shear, snap break testing on cosmetics

Tension

The stickiness of a product is indicated by the adhesive force, which is measured by the return, tension and stroke of the test (Figure 9). Stickiness in a cream may be undesirable, especially if a silky feel is expected. The stickiness of moisturizers can be evaluated by tension testing.

Figure 9. Tension testing on cosmetics

Gel Testing

Gelling agents have found their way into most cosmetic product formulations. There are a set of standard tests prescribed by the gel industry for raw ingredients or final products that take the form of a gel, and these may be performed to evaluate the strength of formulations (Figure 10).

Figure 10. Gel testing

Gel testing may be done for evaluating the bloom strength and for comparing the hold strength of hair gels.

This information has been sourced, reviewed and adapted from materials provided by Mecmesin.

For more information on this source, please visit Mecmesin.