The storage and loss modulus of tires has usually been measured using Dynamic Mechanical Analysis or DMA. This testing technique is able to accurately measure both properties, which help predict rolling resistance and wet traction. Important information for tire manufacturers. Here spatially resolved DMA is demonstrated using oscillatory indentation with an iNano indentation system produced by Nanomechanics, Inc.

Materials and Methods

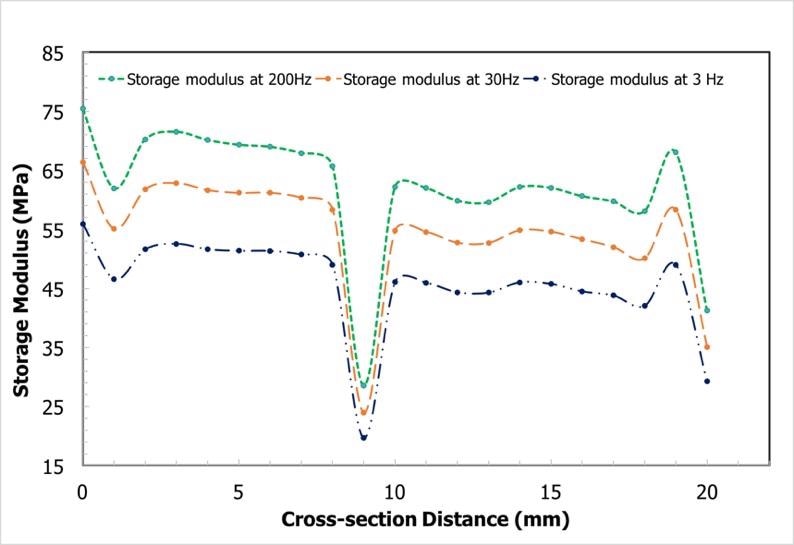

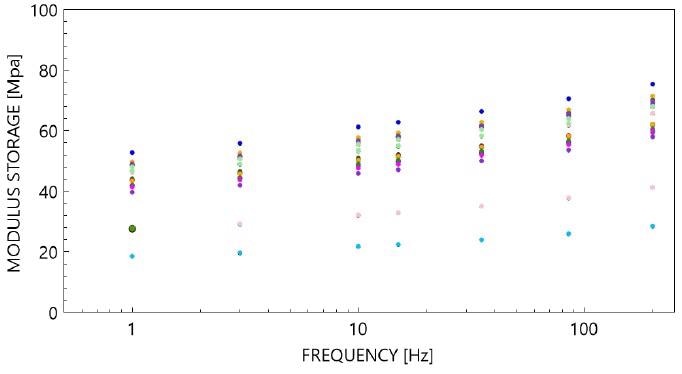

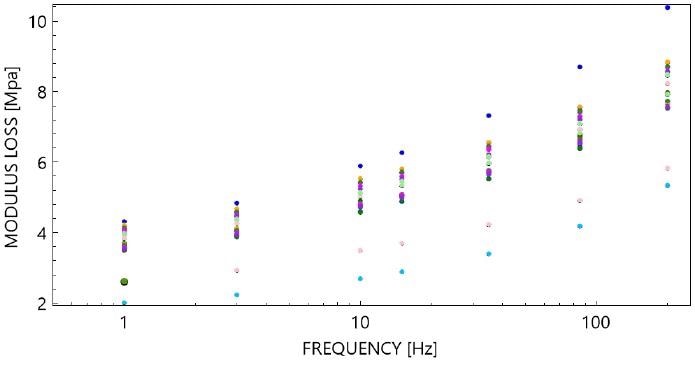

The testing sample was taken from a Bridgestone tire and embedded into an epoxy mount. The surface was then polished to ready it for the nanoindentation experiment. The Polymer Pack option for the iNano was used during the testing performed in this experiment. A flat-ended punch with a diameter of 100 µm was used to make the contact based DMA measurements. The target area for testing was placed between two steel belts. 21 dynamic indentation tests were done, with each test being performed 100 µm apart. At each test site, the system pressed the punch face into full contact and then measured storage and loss modulus represented by E’ and E” respectively. The measurements were made by oscillating the indenter at frequencies from 1 to 200 Hz. The iNano system measured the DMA properties as a function of both position and frequency.

Figure 1. Cross-section of the tire sample embedded in epoxy, polished and ready for testing. The multiple polymer layers are apparent in the cross-section. A vector of tests was performed along the yellow line across the sample, proceeding upward.

Table 1. Test Inputs.

| Frequency sweep |

Poisson’s ratio |

Target Dynamic Displacement |

Pre-test compression |

Punch Diameter |

| 1-200 Hz |

0.499 |

50 nm |

0.1 µm |

107.4 µm |

Results and Discussion

It was found that the storage modulus decreased for test sites closer to the outer part of the tire. About half-way across the testing area, the storage modulus decreased sharply; this indicated a very different material would be present at that location. It was found that the storage modulus increased with frequency at all tested positions.

The storage and loss moduli increased steadily and significantly with frequency. However, the loss modulus increased more as a function of frequency. In the real world this would mean that the tire material would damp more energy at higher frequencies. As polymers manifest time-temperature correlation, they will exhibit analogous behavior with temperature. This means that both the storage and loss moduli are likely to increase with decreasing temperature. The loss modulus will become more dominant as temperature decreases.

Conclusions

Testing with contact-based DMA has more advantages relative to traditional DMA. As shown by the oscillatory indentation technique used in this experiment to measure the local complex modulus of a cross-section of a tire. Testing requires only a flat surface unlike traditional DMA testing that would need a sample of a specific geometry. Testing is fast and automated using the iNano system. Another advantage is that the measurements are local, revealing important spatial variations in properties.

This information has been sourced, reviewed and adapted from materials provided by Nanomechanics, Inc.

For more information on this source, please visit Nanomechanics, Inc.