The non-invasive TSP431-W provided high levels of accuracy simply by exploiting the thermo-mechanical optimization potential. However, it was natural to improve this accuracy further by using model-based algorithms, taking into account the ambient conditions during measurements. Ambient temperature plays a particularly important role in this process.

The newTSP341-N temperature sensor, presented here, is the result of the successful implementation of this demanding development goal.

The non-invasive temperature sensor combines the established HART communications protocol in two-wire technology with non-invasive temperature measurement. As a result, the sensor can be seamlessly integrated into existing system structures.

The non-invasive temperature sensor TSP341-N (display optional).

The calculation algorithms in ABB’s non-invasive temperature sensor increase the accuracy of the surface measurement significantly because they take the ambient conditions into account during measurement.

There are two temperature sensors in the TSP341-N. As well as measuring the surface temperature at the measuring point, the ambient temperature in the vicinity can also be measured. The sensor has a temperature transmitter that has a current output of 4 to 20 mA and communicates using the HART 7 protocol which is based on the successful, market-established TTH300 HART by ABB.

The non-invasive temperature sensor calculation algorithms are built into the transmitter firmware and calculate and output the process temperature over a measuring range of -40 oC to 400 oC (-40 oF to 752 oF), in real time.

The TSP341-N has a connection head made of stainless steel or epoxy-coated aluminum and an optional LCD indicator.

Suited measurement media and their parameters for non-invasive temperature measurement using the non-invasive temperature sensor.

A high-level of user friendliness was a special development goal for the TSP341-N sensor. The device should be easy to operate and it should be possible for it to be put into operation immediately following the simple surface installation. Consequently, knowing whether there is an insulation present at the measuring point (present at delivery) or not is the only parameter relevant for the non-invasive temperature sensor calculation algorithms.

Other parameters, for example thermal conductivity coefficient of the vessel or pipping, thickness or material, or even specific information on the geometry and material of the insulation are not needed for correct and accurate operation of the sensor. This also simplifies the ordering process for the TSP341-N, and later the device can be used flexibly at different measuring points.

Extensive research has shown that, for many applications scenarios, the temperature of the inner wall, outer wall and process (measuring medium) may be assumed to be practically the same for metal pipes and vessels. Therefore, no calculation for the difference in temperature between the pipe inner wall and outer wall is not necessary and the corresponding parameters for this calculation are not required.

The high non-invasive measuring accuracy of the TSP341-N is achieved by a) special correction algorithms and b) thermo-mechanical optimizations and documented in the following chapter by measurement results. As a result the surface temperature of the outer wall (of the vessel or piping) can be determined very precisely. Assuming that there is no significant difference to the process temperature, it is also possible to determine the temperature of the measuring medium with great accuracy.

However, even with metal pipes, the concept of temperature uniformity between the outer wall and the process is not applicable for all measuring media and application scenarios.

Scenarios that are especially suited for this concept include: media with high thermal conductivity, processes with high medium velocity or turbulent flow and low-viscosity measuring media. Examples include: water, water-based liquids and watery solutions and also saturated steam or fast flowing oil. Often, however, the temperature of the measuring media (or the process temperature) may be calculated accurately enough for other flow behaviors and materials, and this is sufficient for the specific application.

The examples that follow show, for substrates of different thermal conductivity and viscosity, what can be expected in terms of measuring accuracies at different pipe diameters and medium velocities in non-invasive temperature measurement using the TSP341-N.

Metallic piping and insulation at the measuring point are assumed for calculations with the help of empirical formulae. The following parameters are considered:

- Dynamic viscosity η and specific thermal conductivity λ, represented with typical materials in three examples

- Ambient temperature Tamb

- Temperature of the measuring medium Tm

- Temperature of the outer wall Tsurf

- Pipe diameter D

- Medium velocity v

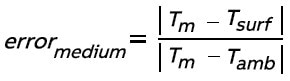

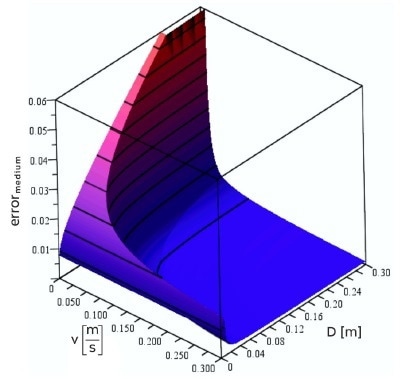

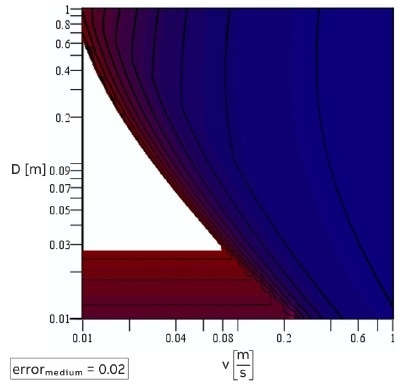

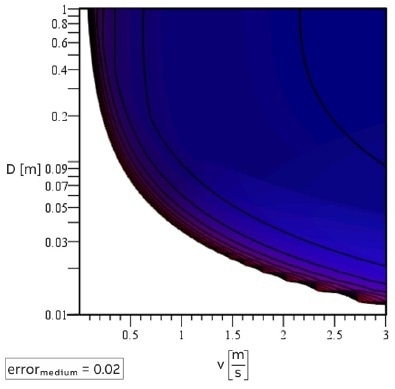

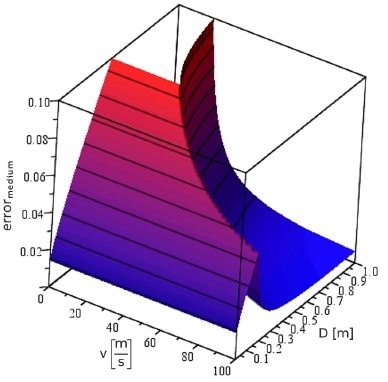

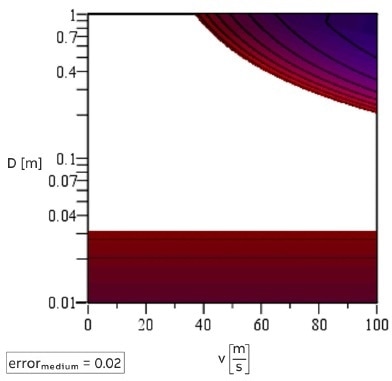

The three-dimensional presentation on the left of examples 1 to 3 respectively, demonstrates the relative measuring accuracy as a function of pipe diameter D and medium velocity v.

Therefore, the following information errormedium = 0.02, referred to in the following examples as ΔTerr = 2 K, should be interpreted as a measuring accuracy of ± 2 K pro 100 K of temperature difference between the environment and the measuring medium.

The possible combinations of pipe diameter and medium velocity for a measuring accuracy of ΔTerr ≤ 2 K are shown on the right side of examples 1 to 3, partially scaled logarithmically.

Example 1 – Liquids with Low Viscosity

Measuring medium: water, dynamic viscosity η ≈ 1 mPa s

Result

- Even at very low medium velocities (v > 10 cm/s), the accuracy is always high, regardless of pipe diameter.

- Turbulent flow almost always occurs with low viscosity liquids such as water, regardless of medium velocity v and pipe diameter D.

- The calculations show a high level of accuracy for all medium velocities for small pipe diameters (D <3 cm).

Measuring accuracy with low viscosity liquids, for example water.

Conclusion

- For the TSP341-N, featuring non-invasive measurement, very high accuracy can be expected for most low viscosity liquid applications.

Possible combinations of medium velocity and pipe diameter for the measuring accuracy ΔTerr ≤ 2 K.

Example 2 – Liquids with Low Thermal Conductivity and Increased Viscosity

Measuring medium: Oil, specific thermal conductivity λ ≈ 0.14 W/m K, dynamic viscosity η ≈ 13.4 mPa s.

Results

- A turbulent flow behavior of the liquid is required for high level of measuring accuracy.

- With a larger pipe diameter D and higher medium velocity v, high measurement accuracy can be achieved. For example, with a medium velocity of v > 70 cm/s is required for a pipe diameter of D = 5 cm.

Measuring accuracy for liquids with low heat conductivity and increased viscosity, for example oil.

Conclusion

- For liquids with increased viscosity and low thermal conductivity, non-invasive measurement using the TSP341-N with very high accuracy is possible for larger pipe diameters and medium velocities.

- A possible insufficient accuracy can be expected due to the physical conditions in other cases. ABB will gain further experience here within the scope of special test setups and pilot projects.

Possible combinations of medium velocity and pipe diameter for the measuring accuracy ΔTerr ≤ 2 K.

Example 3 – Liquids with Very High Viscosity

Measuring medium: honey, dynamic viscosity η ≈ 10 000 mPa s.

Results

- The calculations show a high level of accuracy for all medium velocities for small pipe diameter D ≤ 3 cm.

- Turbulent flow almost never occurs with very high viscosity liquids such as honey, regardless of medium velocity v and pipe diameter D.

Measuring accuracy with very high viscosity liquids, for example honey.

Conclusion

- Regardless of the medium velocity, non-invasive temperature measurement using the TSP341-N with very high measuring accuracy is possible, for liquids with very high viscosity, for small pipe diameters.

- The accuracy decreases for larger diameters and only increases again in unrealistic ranges of medium velocity. ABB will gain further experience here within the scope of special test setups and pilot projects.

Possible combinations of medium velocity and pipe diameter for the measuring accuracy ΔTerr ≤ 2 K.

Summary

The three examples given show that the TSP341-N is outstandingly suited for a large number of applications. As well as the calculations for these three samples, ABB has conducted many more studies on the accuracies achievable for a broad variation of applications and materials. Presenting them would go beyond the scope of this document.

ABB has now got stimulation programs, and these enable good assessment of the achievable accuracy of the TSP341-N in a specific application.

This information has been sourced, reviewed and adapted from materials provided by ABB Measurement & Analytics.

For more information on this source, please visit ABB Measurement & Analytics.