Living habits have dramatically changed in recent years and ideas are spreading much faster as younger generations migrate to cities and embrace increasingly digital lives.

Image Credit: gyn9037/Shutterstock

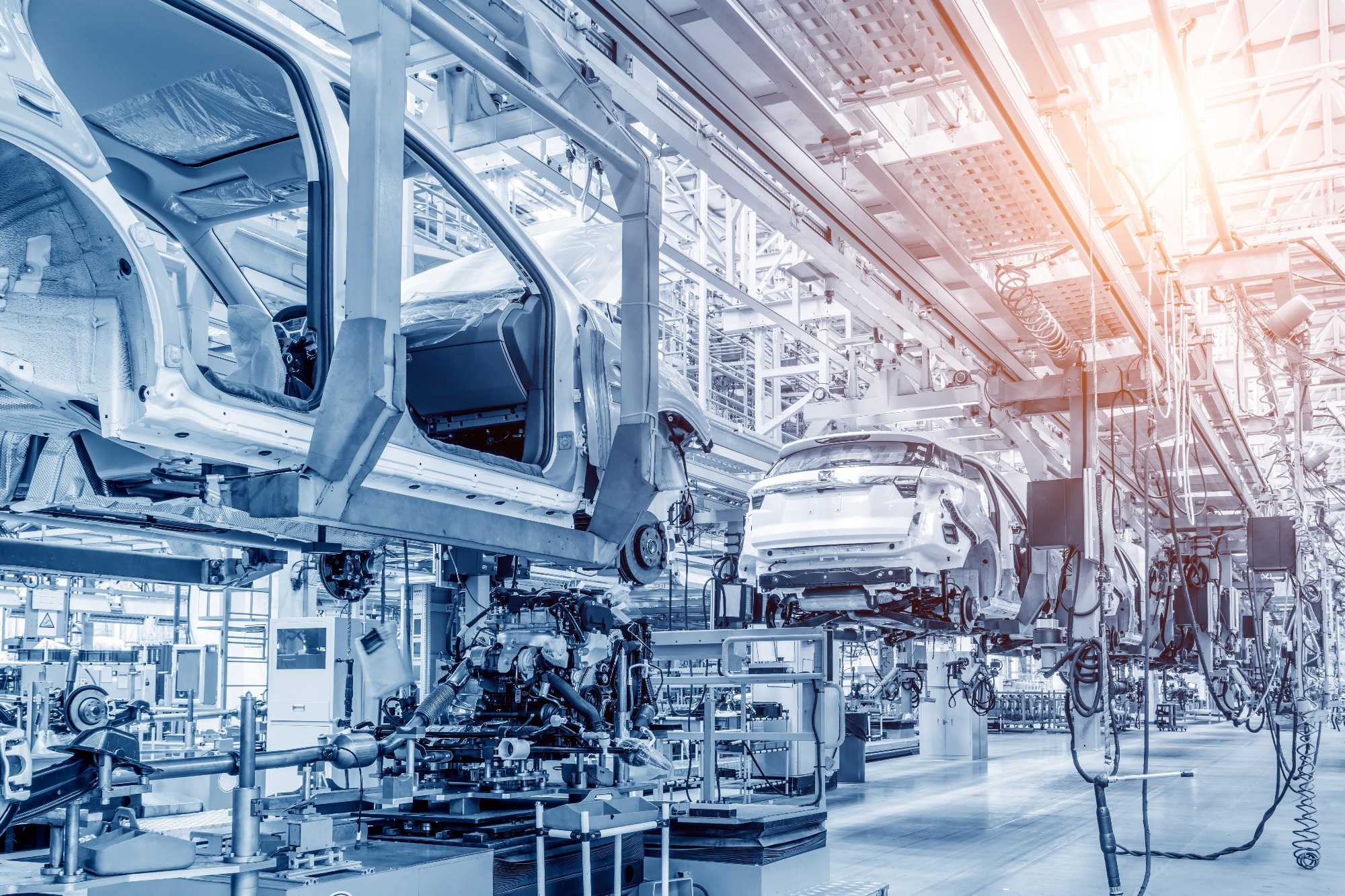

A number of industries are affected by these changing demographics, in part due to their high fluidity. For the automotive industry, the quickly developing concept of shared transportation is set to disrupt the landscape as we know it.

The improving proliferation of AI technologies, 5G networks, and electrical energy is quickly permitting a wider variety of and more personal transport options, where consumers can play games, watch movies or work while traveling, with the freedom to choose both the time and route of transport.

It's important to note that these alterations are not an indication of the end of cars, or even the internal combustion engine. Cars will still be a crucial part of the mobility mix, but the mix itself will be more diverse and different choices will be available. The automotive industry must prepare for a fundamental change.

Challenges Facing Automotive Manufacturers

By 2030, it is predicted that between 10 and 20 % of all cars will be propelled by battery instead of hybrid power or gasoline. Tighter restrictions on CO2, emissions, and noise will also affect the methods in which automobiles are manufactured, as climate change and sustainability continue to be a vital issue for both consumers and policymakers.

When it comes to manufacturing the cars of the future, well-publicized disruptors such as Tesla regularly hit the headlines, but from within the automotive industry, existing OEMs and top-tier parts suppliers are also pushing the boundaries.

In 2019, Ford CEO, Jim Hackett pointed out that his company had been investing in ‘disrupting’ technologies long before Tesla, whilst ambitious sales targets for full-electric vehicles have been set by another traditional player, Toyota.

Nissan, alongside EVgo, has pledged to install 200 fast chargers in the United States to support customers buying electric cars. This power-struggle between old and new shows how traditional giants and disruptive players are pushing each other towards impactful technological developments.

As consumers become more focused on customization, intelligence, aesthetics, and sustainability, automotive companies have to come to terms with these alterations and find solutions in their manufacturing processes. These solutions can be found in the adoption of more innovative and lighter materials.

Finding new ways to produce parts more efficiently and effectively has become vital, with automotive manufacturers facing new challenges daily, from financial pressures to changing industry trends.

Superhard Materials as a Solution

To precisely and effectively machine components, super-hard materials can be one such solution – in an average car there are a minimum of 150 application groups that currently rely on super-hard materials.

Element Six supplies superhard material solutions, including cubic boron nitride (CBN) and polycrystalline diamond (PCD) to help their customers combat these growing challenges. They work in collaboration with toolmakers and OEMs to create solutions from ingredient level, and go through many phases of testing in varied tooling environments to make sure that their materials achieve optimum performance.

Increasingly, automotive customers are demanding that electric cars be more sustainable and do more, meaning manufacturers must maximize efficiency and machining speeds, while keeping costs low.

End-users experience better resistance to chemical wear, increased toughness and greater reliability in the machining of hardened steel by eliminating impurities in the tooling materials used, mainly utilized in drivetrain gears and bearings. This also increases tool life and efficiency in the machining process.

Element Six has eliminated impurities in PureCut™, their polycrystalline cubic boron nitride (PCBN) range of specialist machining tools, surpassing industry benchmarks and leading to significant cost savings for customers.

With the pace of technological change in the automotive industry unrelenting, and end-users and customers demanding more, locating marginal gains can set you apart from your competitors.

A smart choice of tooling material allows faster machining speeds and better wear predictability with superior quality per part. Superhard materials can enhance productivity and lower machining costs significantly, which is extremely important in an age where customer expectations are ever-higher.

Tooling materials may not be an obvious source of productivity but selecting the right solution may give you the edge demanded by customers.

This information has been sourced, reviewed and adapted from materials provided by Element Six.

For more information on this source, please visit Element Six.