|

Ceramics can be metallised for brazing using a plating process. A ceramic such as Alumina is plated with a metal and then the part can be brazed with common braze alloys and techniques as simple as an oxy-acetylene torch.

Titanium in Braze Alloys

Originally the thinking was that Titanium is beneficial in active braze alloys so it might be possible to work with material containing Titanium using standard brazing methods. This technique is currently used on Titanium Carbonitride and similar Titanium based materials. It also works well on materials that contain titanium such as grades of alumina with TiC added.

Ceramic Bonds and Bonding of Ceramics

Because ceramics are so tightly bonded you do not need to effect much of the material to get a strong bond. Whatever you can attach to on the surface will serve as a solid anchor for the rest of the part. This has lead to directly effecting Alumina and Silicon as in Silicon Nitride.

Increasing the Reactivity of Ceramics

Ceramics once regarded as non reactive can be made slightly reactive by the use of strong acids and a great deal of electrical energy applied in a manner consistent with standard electroplating tools and techniques.

Treating Alumina for Brazing

|

|

|

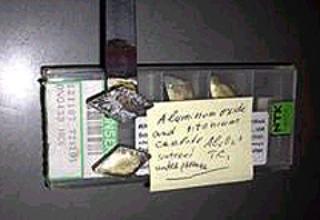

Figure 1. The effects of different surface treatments (see text below).

|

These four parts show the effects of our surface treatment process on alumina

The left part is an untreated part as purchased from a machine shop supply house. The second part is an untreated part we tried to braze. The braze alloy formed a nice sphere in the middle of the part. There was no part wetting. The third part has been treated with our surface treatment. The little dark spot at the top was where the part was held during treatment. The fourth part shows an insert coated with braze alloy. The lower edge shows wetting so strong that the capillary action overcame the edge effect barrier. In other words, the alloy did not spill over the edge but migrated through the material surface. The alloy used was Bag-22 AWS silver braze alloy. It was brazed in an ambient atmosphere furnace using Engelhard Black Flux.

Typical Specifications for Brazed Parts

• This part can braze with tensile strength up to 90,000 psi.

• It is suitable for use with temperatures up to 1200 F.

• The High Impact alloy makes it suitable for use in impact situations such as saws.

• Low cost - The cost of pretinning can be well under a dollar. Pretinning is the application of the braze alloy to one part before joining.

Materials Choice and Suitability

The Alumina parts used are machining inserts because they are well made and readily available. They also illustrate the ability of this process to deal with currently available commercial products. The Alumina parts are NTK insert DNMG433 HC6 reference numbers = HC6DNGN433-TN (5752647). This is a TiC - Al2O3 combination.

Torch Brazing Alumina

We took Alumina machining inserts and metallised them according to US Patent 6,322,871.

We used alumina machining inserts to prove this process would work on readily available tool materials.

Process Overview

Our process is an electrocleaning followed by an acid etch and a plating. These have all been tried before. We just made it work better cheaper, faster and more reliably than anyone else. We can use different chemicals to effect different materials.

We used a hand held oxy-acetylene torch but you can use any heating means you wish. We used a hand held torch to show it could be done with a crude method.

Pretinning

We pretinned the parts first with a Bag-24 filler metal. This is also known as braze alloy or silver solder. This is a 50% silver with copper, zinc and a little nickel. It cost about $8.00 an ounce. We used about $0.06 worth of material to pretin this part before brazing.

On a commercial basis these parts can be treated for about $0.025 per square inch. In this case ‘square inch’ is determined by multiplying the two longest dimensions.

|

|

|

|

|

Figure 2. Brazing a pretinned NTK HC6 alumina/titanium carbide inset to a steel bar (above) and the finished product (below).

|

|