Image Credit: ZwickRoell GmbH Co. KG

The thin film industry is a crucial aspect of day to day life. Thin films are a necessity of modern life, from sterile medical applications to protecting solar panels or keeping food fresh. Plastic films can range from complex, multi-layer films with varying layered properties to cost-effective commodity plastics.

ZwickRoell provides support in attaining critical material properties throughout the production and processing of plastics films. ZwickRoell extrusion plastometers ensure that the material is suitable for processing conditions for raw material checks. Often, establishing the melt index of the raw material is a key step in an incoming goods inspection.

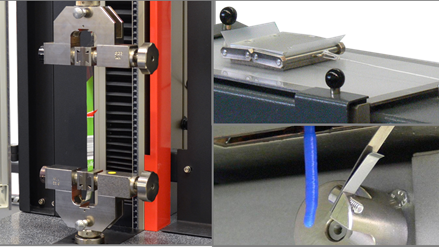

After material processing, a ZwickRoell Universal Testing Machine can carry out a number of required mechanical tests. The stress-strain characteristics, coefficients of friction, adhesion forces, or flexure properties can be established in varying force ranges.

From grips to load cells, all of ZwickRoell’s test accessories are engineered and produced in Germany. ZwickRoell’s testXpert III software is easy to configure and switching between tests is quick and efficient.

For certain applications, the toughness or puncture resistance of a film is vital. For these applications, ZwickRoell can provide impact testing equipment. These instruments include pendulum impact machines for Izod, tensile impact or Charpy pendulum impact.

Drop weight testers for multiaxial puncture tests are also available. All ZwickRoell instruments are also supported by testXpert III software, making training easy and intuitive.

Testing of Thin Sheeting and Plastic Films

Plastic films are now an integral part of daily life. They are used to carry groceries home from the store, package food, and cover vegetables grown in fields and greenhouses. In the medical engineering industry, film packaging is common and often saves lives.

A large variety of films are also utilized in construction. Moisture barriers make sure that our roofs do not leak and water does not damage the walls of our homes. Sophisticated plastic films are utilized to cover sports arenas, opening up new possibilities for architects.

Today, films are high-tech products which have a large variety of characteristics. Mass production utilizes cost-effective plastics, such as low- and high-density PE, PP, PVC, and PS.

In instances where special characteristics like permeability, toughness, or light resistance are needed, high-quality polymers, for example, various polyesters, PTFE, or ETFE are employed.

Films like EVA and EPDM are utilized to waterproof roofs. Multilayer films have a number of characteristics like suitability for contact with food, strength, and impermeability in regard to gas and bacteria.

A constituent material for many hollow bodies in packaging technology is thin sheeting with a thickness of up to 1 mm, this is formed by means of processes like compression molding or thermoforming.

Requirements of the applicable test technique greatly vary due to the broad scope of film manufacture and its downstream processing. The objectives of the tests can be extremely different in nature. In an incoming goods inspection, the first step is testing raw material. This step establishes the melt index, meaning the melt mass-flow rate, of plastic granulate.

Secondly, the plastic films are tested after the blow molding or extrusion process. A number of other mechanical characteristics are important in addition to testing film thickness.

These are strain, strength, yield point, and the tensile modulus in the transverse and longitudinal directions of the film. Toughness is also vital, which is established during impact tests. Adhesion between the layers is crucial in the instance of multilayer films.

Yet, during and after processing the focus is on other characteristics, including weldability, adhesive strength, and strength of joints and adhesives. The puncture resistance of the film is measured if sharp objects are packaged.

For packing machines or in film printing, understanding the coefficient of friction is interesting. Alterations in moisture and light are also vital when assessing thin sheeting and plastic films.

ZwickRoell testing systems are designed specifically for these requirements and address a large range of mechanical tests:

- Pendulum impact testers are utilized to establish impact strength values, usually in an impact tensile test.

- Creep test benches measure the creep behavior at room temperature and at operating temperature.

- Universal testing machines supply reliable, accurate measurement of values for adhesion forces between two layers, coefficients of friction, stress-strain characteristics, penetration resistance and flexure characteristics.

- Extrusion plastometers characterize the materials of incoming goods.

This information has been sourced, reviewed and adapted from materials provided by ZwickRoell GmbH Co. KG.

For more information on this source, please visit ZwickRoell GmbH Co. KG