Image Credit: tec5USA Inc

When considering renewable fuels, biodiesel is an exciting alternative energy source with great promise. The production of biodiesel fuel involves oil-based plant feedstock containing triglycerides, such as seed oil and soybean.

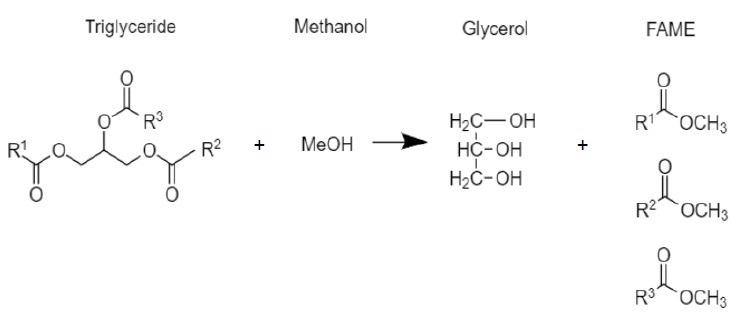

The process necessitates the transesterification of triglycerides with methanol or ethanol to generate long chain fatty acid methyl esters (FAME), as exhibited in Fig. 1.

Figure 1. Mechanism for the transesterification of triglycerides to fatty acid methyl esters (biodiesel fuel). Image Credit: tec5USA Inc

Conventional methods for quality analysis of the biodiesel production process use offline testing methods, which occur at the end of a production cycle.

These techniques increase the cost of production due to the necessity of process stopping, time consuming analytical tests and possible reprocessing if the product does not meet specification. With in-line NIR spectroscopy, real-time measurement of different parameters throughout the transesterification can be performed.

These measurements in include diglycerides, methyl ester, monoglycerides and triglycerides concentration levels. Understanding the levels of glyceride present throughout the reaction process enables precise control of the transesterification process.

Ultimately, this will limit the time and costs incurred to produce biodiesel fuel.

tec5USA Compact Near-Infrared Spectrometer (CNIRS)

Real-time analysis of glyceride levels is made possible with the Compact Near-Infrared Spectrometer (CNIRS). The CNIRS can withstand the hazardous conditions present in the industrial production environment and is readily available as a Class I Division 1 rated device.

The device merges a maintenance free miniaturized NIRONE™ Fabry-Perot sensor module with MEMS technology, the tec5USA tecSaaS® embedded electronics platform and a miniaturized dual halogen light source.

The fusion of these components results in a compact and cost-effective device. With the tecSaaS® embedded platform, additional hardware such as a PC is eliminated for processing of the resulting output; the results can be transmitted via Modbus TCP, EtherNet/IP, CAN Bus and 4.20mA current loop protocols.

IP65 Compact Near Infrared Spectrometer (CNIRS). Image Credit: tec5USA Inc

Class I Division 1 Compact Near Infrared Spectrometer (CNIRS). Image Credit: tec5USA Inc

Measurement

The Compact Near-Infrared Spectrometer (CNIRS) system was used to recognize the features of the transesterification process of radish seed and soybean oil to biodiesel fuel (FAME).

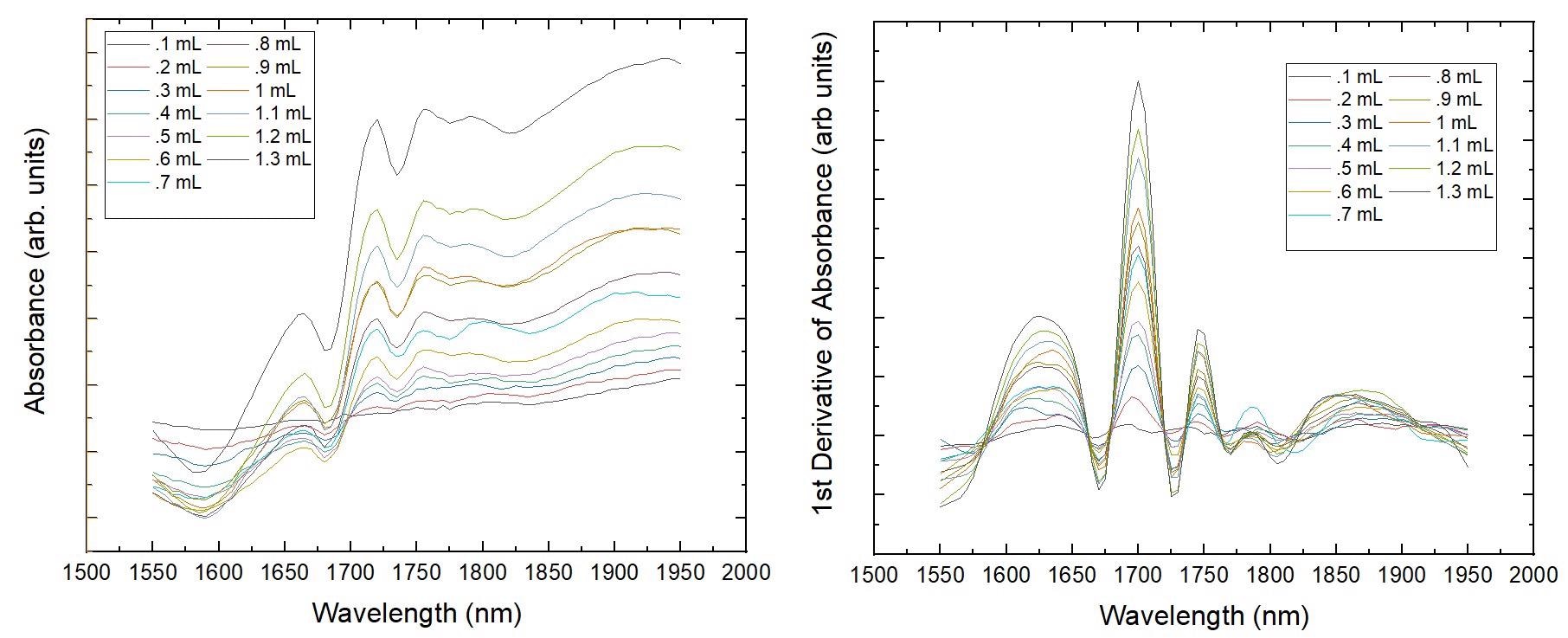

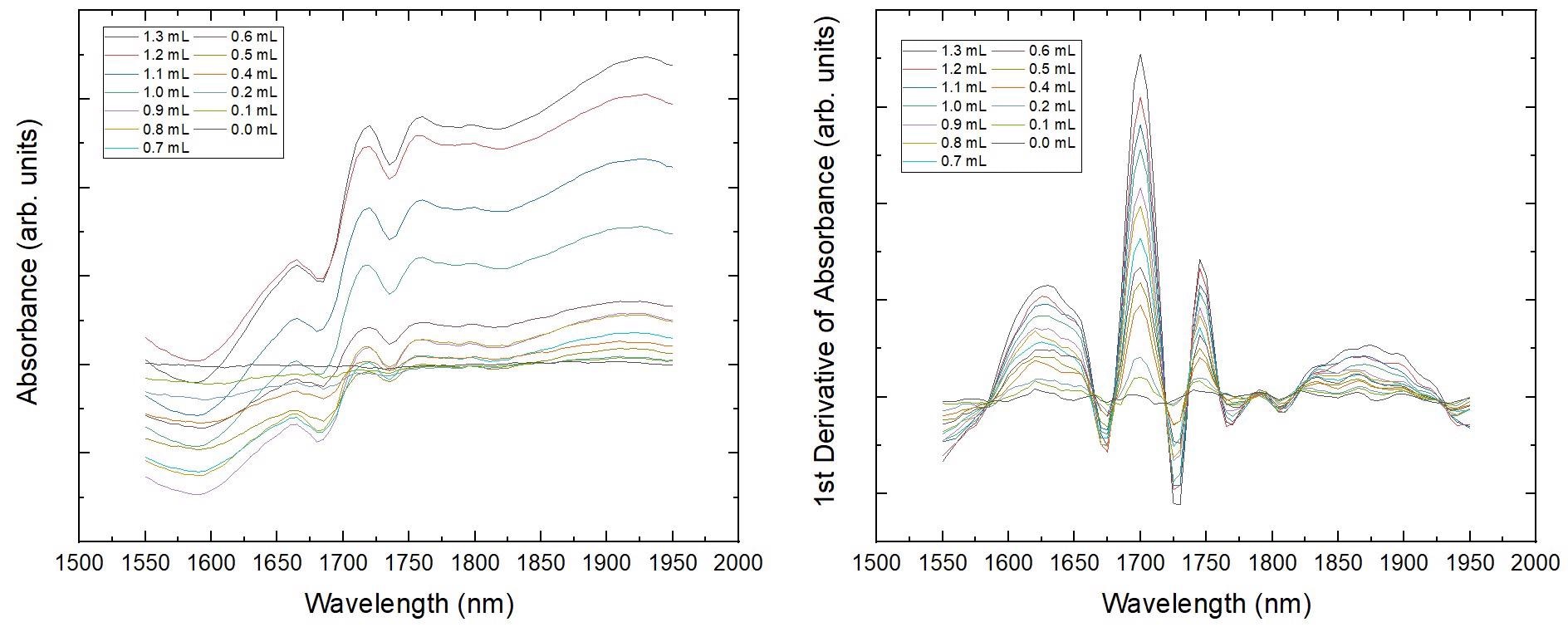

Throughout this measurement, seed and soybean oil were steadily observed as the concentration in ethanol reduced. This decrease in concentration can be seen primarily in the wavelength region between 1620 nm and 1880 nm on Fig. 2a and 3a. This region correlates with the first overtone region of C-H stretching in glyceride.

Figure 2. (a) NIR spectra and (b) 1st derivative for the decreasing concentration of radish seed oil in ethanol. Image Credit: tec5USA Inc

Reducing the concentration from 1.3 mL to 0.1 mL led to a decrease in intensity of the absorbance bands in this region. This intensity reduction is clearly seen by the first derivative spectra illustrated in Fig. 2b and 3b.

Figure 3. (a) NIR spectra and (b) 1st derivative for the decreasing concentration of soy bean oil in ethanol. Image Credit: tec5USA Inc

The relative changes in peak intensity enable quantitative measurement of the glyceride levels throughout the transesterification process.

To ensure the highest product yield is achieved, it is mandatory to completely transform the reactant (seed and soybean oil) to product (biodiesel fuel). By observing the concentration of the reactant throughout the process, operators can modify the reaction conditions in real-time to facilitate the greatest yield.

A complete understanding of this process enables cost reduction, decreased production times and enhanced quality of biodiesel products.

This information has been sourced, reviewed and adapted from materials provided by tec5USA Inc.

For more information on this source, please visit tec5USA Inc.