The Fourth Industrial Revolution has Arrived

Today, perhaps no sector has seen such rapid changes as the manufacturing industry. In order to produce their goods faster, maintain their quality and ensure the process is cost-effective, modern manufacturing companies are embracing the latest technological advances.

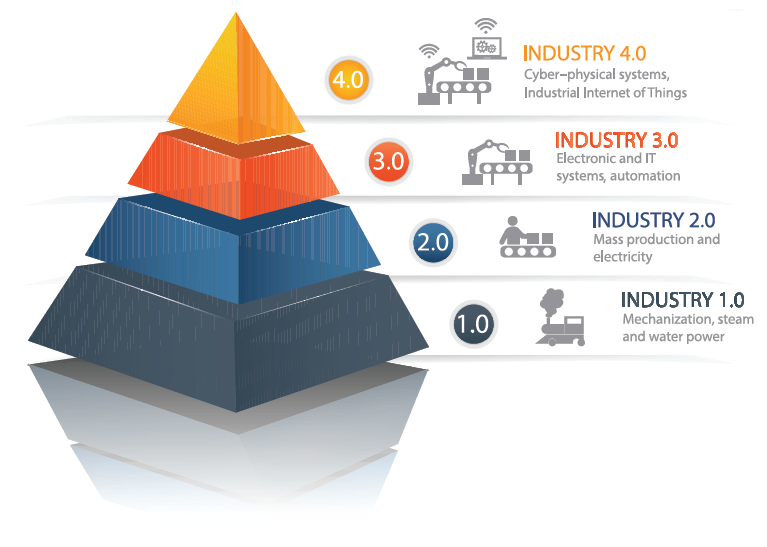

Several of these advances are cyber-physical systems (CPS), along with the Industrial Internet of Things (IIoT) and cloud-based computing, networks and more.

Such advances help manufacturing companies to bring in new levels of effectiveness and manage real-time business data, meaning that they play a pivotal role in the creation of a fully connected 'smart factory.'

The advent of smart factories all around the world has led to both impressive throughput and enhanced productivity – helping businesses to boost profits and deliver stronger, more profitable business results. This revolution is commonly termed ‘Industry 4.0’ and has come to be known as the fourth industrial revolution to many.

Image Credit: Ambrell Induction Heating Solutions

The Four Industrial Revolutions

The first revolution took place between the late 1700s and early 1800s and primarily revolved around the transition from inefficient manual labor and the use of farm animals to the transformation of utilizing water and steam-powered engines. This transition was famously instrumental in improving manufacturing output and augmenting the labor force.

Image Credit: Ambrell Induction Heating Solutions

The second revolution took place between the early 1800s to the mid-1900s and was characterized by the advent of automobiles, airplanes and telecommunications – which, as we know, would ultimately change the way of life for good.

Manufacturing was also changed permanently thanks to the introduction of electricity during this period: providing factories with a new form of power generation which would redesign manufacturing methods.

Henry Ford’s famed introduction of the assembly line and mass production of cars (namely the Model T) at Ford Motor garnered him global attention, as did his automation of mechanical processes in the factory. Ford’s automation allowed him to produce a great deal more automobiles, with the added bonus of consistent quality from one car to another.

Image Credit: Ambrell Induction Heating Solutions

The emergence of technology marked the third revolution, changing our way of life forever. This included first-generation computers, which came into being on the factory floor.

Many companies were beginning to move away from analog and mechanical methods of manufacturing by the 1950s-1960s, instead introducing digital technologies (marked chiefly by computers and automation programming), which we might today think of as the early stages of software.

Productivity and manufacturing gains continued their stratospheric rise as more advanced computers – including robotics machinery - were developed in the 1980s and through the first ten years of the 2000s.

Image Credit: Ambrell Induction Heating Solutions

Manufacturing experts began to embrace major advances in technological innovation for use in manufacturing processes from the 2010s onwards. This decade marked the start of the fourth industrial revolution - or what we might term ‘Industry 4.0’. Industry 4.0 centers around how factory equipment, artificial intelligence, cloud-based computer systems, networks and more are interwoven.

This linking of various Industry 4.0 aspects provides real-time, precise manufacturing data, which helps companies better analyze production and manage their output, to optimize performance, productivity, processes and profits.

Ambrell is able to assist manufacturing companies as they transition into the fourth industrial revolution. Ambrell has a wealth of knowledge when it comes to induction heating systems designed to meet Industry 4.0 requirements.

Ambrell products like the EASYHEAT and EKOHEAT are ideal for companies confidently embracing the most advanced technologies of the modern Industry 4.0 factory.

Industry 4.0 and Ambrell Induction Heating Systems

Industry 4.0 technologies like the ones explored in this article are certain to help advance the way manufacturing companies around the world design, prototype and manufacture their products.

An important role in this advancement is played by the real-time collection of data. For managers, factory personnel and engineers to track and achieve their KPIs and manufacturing goals, analysis and conversion of this information into actionable data is essential.

Ambrell has delivered thousands of successful induction heating solutions globally over the last three decades, across a huge range of applications and industries. All EASYHEAT and EKOHEAT products have a data collection functionality which has been essential in the success of their heating solutions.

Ambrell’s customers can collect this data simply by querying the RS485 port or by utilizing Ambrell’s eVIEW data management software.

Ambrell works in partnership with Industry 4.0 companies to develop an efficient, fast, and crucially repeatable non-contact heating method. Ambrell’s process uses intelligence, data collection, and analytics as part of their unique and innovative approach to garnering extraordinary results for their clients.

The entire range of induction heating equipment has been carefully engineered and designed to meet the manufacturing requirements of Industry 4.0 - meaning that their full product range is fully capable of meeting even the most demanding process heating needs.

Ambrell provides a complimentary consultation service because Industry 4.0 initiatives are naturally different from one manufacturing firm to the next - often with varying levels of performance criteria.

Clients wishing to learn more about how Ambrell’s induction heating systems can work together with their Industry 4.0 manufacturing technologies can take advantage of our consultation service.

Industry 4.0 as Part of Ambrell’s Complimentary Consultation

Ambrell offers a free consultation with Dr. Girish Dahake, Sr. Vice President of Global Applications, in which clients have the opportunity to review their chosen heating application.

Dr. Dahake has over 25 years’ experience in the industry, including problem-solving some of the most challenging heating problems possible, and his expertise is invaluable for heating solution needs.

Image Credit: Ambrell Induction Heating Solutions

Ambrell’s team of engineers can discuss the client’s particular Industry 4.0 requirements and work together with their client collaboratively to help them meet their Industry 4.0 objectives.

This information has been sourced, reviewed and adapted from materials provided by Ambrell Induction Heating Solutions.

For more information on this source, please visit Ambrell Induction Heating Solutions.