An ancient Mayan city complex is being revealed beneath a forest canopy in the jungles of Northern Guatemala. LIDAR measurements are being used to capture and reconstruct ground features in a series of topological points, encoding surface information in a 3D point cloud.

Image Credit: PI (Physik Instrumente) LP

A similar point cloud is forming from a white light interferometer in a sterile laboratory complex that is investigating the tribological properties of numerous titanium alloys.

While these two example applications appear disparate, they, and many other applications employing contact and non-contact surface measurements, leverage the capabilities of 3D Point Clouds as a data convention.

From Characterization to Fabrication – Additive and Subtractive Manufacturing

Consideration must be given to the best approach when the application shifts from characterization towards the fabrication of and on such surfaces. Point clouds are simply a collection of discrete data points represented in a delimited text format of ordered triples.

Fabrication processes’ ability to form trajectory paths requires a surface reconstruction that can be constructed in flexible layers featuring specific intra-layer process paths.

It is essential for these process paths to be adaptable to work with additive (for example, material extrusion or dispense) or subtractive (for example, ablating features into/from a surface) fabrication methods.

Specific processes impose parameter bounds, placing varying demands on parameters such as process speed, layering heights, layer infill and layer process ordering.

Laser Machining - Large Area, High Throughput, High Path Accuracy: PI Motion Systems & Controls

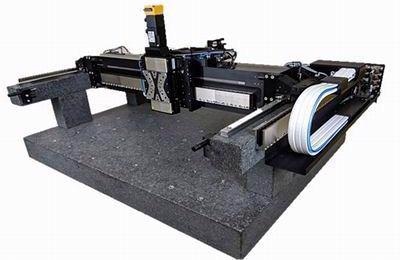

Example of motion system for laser processing based on PI/ACS hardware and controls. Video Credit: PI (Physik Instrumente) LP

Surface Reconstruction and Import into SPC Software

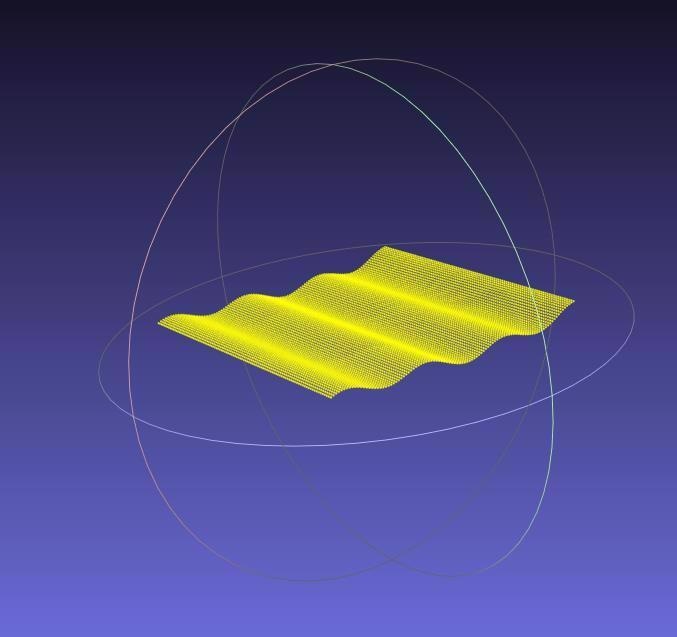

The example presented here looks at a point cloud with a periodic surface structure. A Screened Poisson Surface Reconstruction is applied to construct a triangulated/faceted mesh from the point cloud.

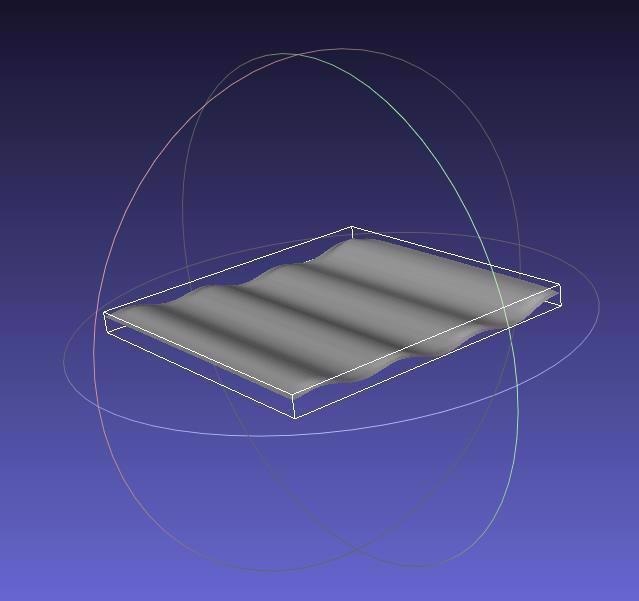

The fidelity of the cloud to the surface is related to measurement resolution, while the relation of the mesh to the cloud depends on a number of variables, including a minimum number of samples, reconstruction depth and interpolation weight.

A point cloud and corresponding meshed surface is displayed, and once this has been appropriately meshed, it is possible to save the surface in STL format before importing this into the SPC Software.

Point cloud with a periodic surface structure. The point distribution can be observed as set of discreet points. Image Credit: PI (Physik Instrumente) LP

Triangulated/faceted mesh built out of the point cloud after Poisson Surface Reconstruction. Image Credit: PI (Physik Instrumente) LP

Meshed surface ready for saving in STL format and importing into SPC Software. The vertices of the mesh are now used to form triangulated facets according to the surface reconstruction. Image Credit: PI (Physik Instrumente) LP

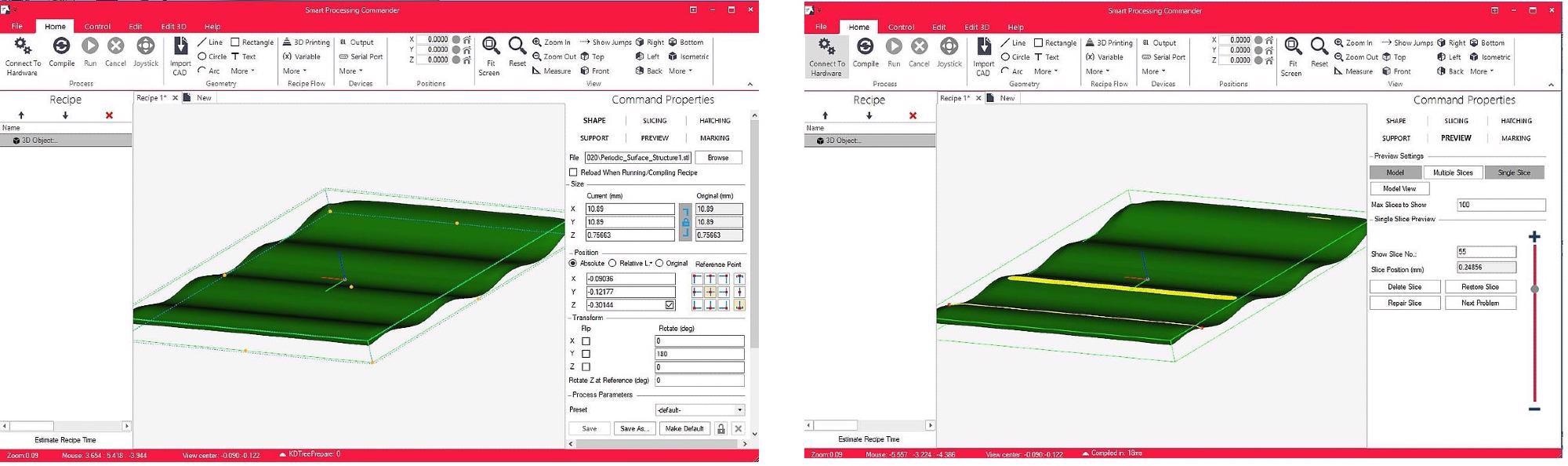

Once it has been imported to SPC, a range of transformations and tools can be applied. These include:

- Scaling; for example, for miniaturization or magnification correction

- Location in the stages’ coordinate space

- Rotational transformation

- Machine vision for alignment or overlay

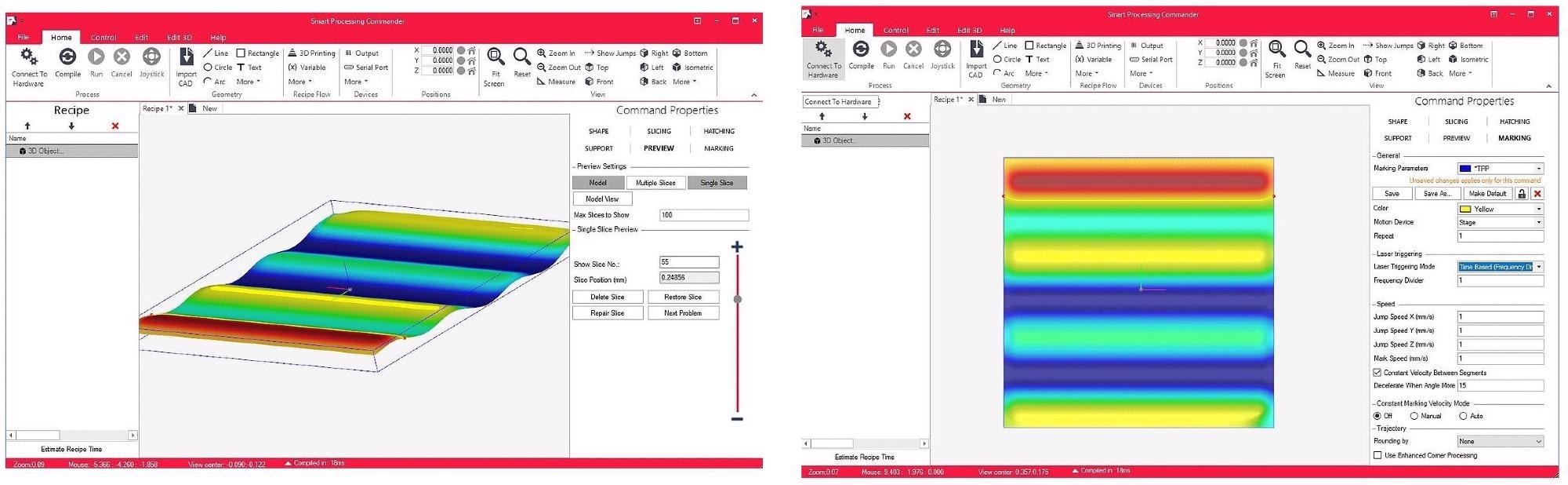

The imported STL is shown in PI/ACS SPC software with good fidelity to point cloud. SPC features multiple layering and infill options with user-defined inter-layer spacing required for flexible additive/subtractive processes. Layering information can be isolated and previewed in the model as shown (or without model in the view). Here, we select and preview a single process layer in yellow (with applied-infill). Image Credit: PI (Physik Instrumente) LP

PI/ACS SPC software features multiple infill and layering options alongside a flexible user-defined inter-layer spacing.

Layering information can be isolated and previewed in the model itself or without the model in view. The surface can be false-colored to enable easier identification of topological features.

False coloring can be applied to the STL to help identify topological features. Here, a color gradient shows the surface topology variation. Deep red shows the highest points on the STL and deep blue shows the lowest. Image Credit: PI (Physik Instrumente) LP

Synchronized Triggering of Lasers or Dispensers

Users can select device-specific process parameters for automatic motion synchronized triggering of a laser, dispenser or extruder. These can be set with independent process speed and jump speed to facilitate reduced process times.

The 3D window will update the process as it runs, providing users with a real-time representation of the model during the fabrication process.

Hardware and Software

These features are included in PI’s standard and custom XYZ gantry stages and multi-axis systems when operated via the company’s motion controllers using ACS. EtherNet/IP, EtherCAT and Ethernet connectivity are also available.

A-341, compact hybrid XYZ high speed and high precision gantry stage system / linear robot with air bearings on the cross axis for smooth, particle-free, high speed motion. Image Credit: PI (Physik Instrumente) LP

A-824, Ethercat based, high performance multi-axis motion controller. Image Credit: PI (Physik Instrumente) LP

Dedicated laser control module for high-performance motion synchronized laser triggering. Image Credit: PI (Physik Instrumente) LP

References

- P. Cignoni, M. Callieri, M. Corsini, M. Dellepiane, F. Ganovelli, G. Ranzuglia | MessLab: an Open-Source Mesh Processing Tool | Sixth Eurographics Italian Chapter Conference, page 129-136, 2008

- M. Kazhdian, H. Hoppe | Screened poisson surface reconstruction | ACM Transactions on Graphics (TOG), 32(3), 29, 2013

This information has been sourced, reviewed and adapted from materials provided by PI (Physik Instrumente) LP.

For more information on this source, please visit PI (Physik Instrumente) LP.