The high purity Chemical Vapour Deposition (CVD) diamond engineered by Element Six has facilitated a ground-breaking fiber-coupled diamond magnetometer, which is on track to improve diagnostics in medicine and aging of structural materials

A team of scientists from the University of Warwick, in collaboration with Element Six, have created the world’s most sensitive fiber-coupled diamond magnetometer. The magnetometer is powered by the properties of synthetic diamond and is able to analyze objects or materials by measuring their magnetic fields using the quantum technology unlocked by diamond nitrogen-vacancy (NV) centers.

The device can be targeted at a range of applications, thanks to Element Six’s engineered NV diamond solution - which is connected by a fiber-optic cable to the processing equipment.

Unlike other existing technologies in the field, this solution doesn’t require cryogenic cooling. Thanks to the device’s leveraging of the room temperature properties of diamond, miniaturization is possible, and therefore, the device becomes portable. Unique properties like these are also ideally suited for diagnostic techniques in medicine, such as Magnetocardiography (MCG).

Magnetocardiography paves the way towards advanced quantum-enabled healthcare solutions, which could make early heart diagnosis a practical reality by measuring the magnetic fields produced by electrical currents in the heart.

The Opportunity: Revolutionizing the Ease of Detection

Magnetometry has a wide application across various fields, such as in mobile phone sensors and cars. To achieve the best sensitivity, however, the sensors are usually both expensive and large, typically requiring cryogenic cooling, which has a negative impact on usability.

Being a relatively small and lightweight table-top solution, the new diamond-enabled device offers a much less invasive piece of equipment compared to some traditional magnetometers. It also has the potential to considerably lower the cost per unit.

Thanks to the fiber-optic cable, the user can aim the diamond sensor from up to 10 m away and hit specific objects. This level of portability and flexibility is crucial in the improved detection of heart diseases, which remain the world’s leading cause of death.

If scaled for mass production, this magnetometer could allow for faster and more accurate detection of heart disease at the point of care – and, in turn, reduced discharge times for patients.

The range of detection can be easily targeted and moved, thanks to the fact that the device is both portable and can be hand-held. These features make it suitable for heavy industry applications, including the analysis of material in bulk for defects like corrosion.

Steel, though it accounts for the vast majority of global metal in production, suffers from corrosion. The new magnetometer has the potential to facilitate easier analysis of steel in situ to detect corrosion and prevent expensive, and potentially lethal, accidents. Therefore, the magnetometer delivers improved safety and cost efficiencies as well.

The Challenge: Obtaining Sensitivity

Sensitivity is vital for both Magnetocardiography and high-value operations, like the detection of corrosion in steel. The magnetometer measures tiny magnetic fields emanating from the surfaces of potentially corroded materials or emitted from the human heart.

Diamond magnetometry, therefore, offers an ideal method of combining temperature operation within a compact system. Element Six’s engineered diamond is perfectly optimized to contain the right concentration of NV center defects to ensure maximum sensitivity whilst minimizing the presence of other defects.

However, it is not easy to achieve the perfect balance: magnetic noise is caused by impurities in the diamond, which reduces the accuracy of the device. Too large a concentration would accrue interference, while too small a concentration of NV centers would render it not sensitive enough.

Given that other factors can also affect sensitivity, like size and surface finish, the Morley group required Element Six to deliver high-quality, synthetic, tailor-made diamond materials.

Laser light shining through a sample of NV Diamond - Image Credit: Element Six

The University of Warwick and Element Six’s Solution: High Quality Diamond Magnetometry

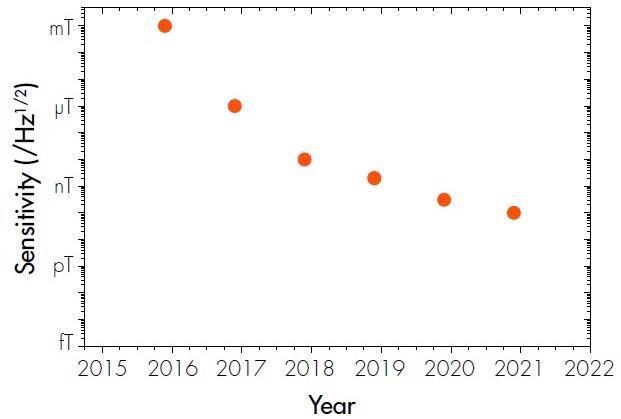

Element Six has worked closely with the University of Warwick for decades to increase accuracy and sensitivity of these technologies. The magnetometer’s sensitivity has improved over five years of experiments by a factor of 10 million, starting from a threshold of milli-tesla to nano-tesla, as evidenced by the below graph.

This makes the technology ideal for use in applications like the detection of steel corrosion and the early diagnosis of heart disease.

Witnessing the sensitivity gains achieved by the immensely talented team at Warwick in such a short period of time has been great. It’s testament to their knowledge of the field and practical expertise. We’re delighted to have made a significant contribution to this innovation and we look forward to seeing our diamond materials unlocking new milestones in the journey to commercializing quantum technology.

Dr. Matthew Markham, Principal Research Scientist, Element Six

Over five years, the fiber-coupled diamond magnetometer at the University of Warwick has improved in sensitivity by a factor of 10 million.

Image Credit: Element Six

The UK Quantum Programme has supported the project by providing significant funding to improve the product’s sensitivity to date. Support is also credited to The Networked Quantum Information Technologies Hub (NQIT) and the Royal Society.

In addition, the team members at the University of Warwick behind the project have graduated through the Centre for Doctoral Training (CDT) in Diamond Sciences and Technology, supported by Element Six.

There’s no doubt that the quality of the diamond and the people I’ve been lucky enough to work with have been vital. They are the two most important factors in our success.

Dr. Gavin Morley, Associate Professor, University of Warwick

Next Steps

The device developed by the Morley group in collaboration with Element Six can detect damage in steel, and it is hoped that it will soon be able to measure a signal from a person’s heart. The next stage is to engineer the ground-breaking solution into becoming a commercialized reality. Dr. Morley anticipates that the user will be able to scale the product down to a sufficient size and shape to fit into a rucksack in the future.

The Warwick team, looking forward to further applications, is additionally considering magnetoencephalography (MEG), which is the science of the detection of signals from the brain.

Though MEG is more challenging, as the magnetic fields from the brain are smaller than those from the heart, the team hope that diamond MEG may eventually be used to diagnose illnesses like early-stage Alzheimer’s disease and schizophrenia.

For our device to work, we need the diamond to be just right. Element Six has been the ideal development partner as the team have encouraged the kind of close cooperation that gets us to the position that we’re currently in. They have manufactured exactly what we were looking for: a diamond that has the right shape, size and spin properties.

Dr. Gavin Morley, Associate Professor, University of Warwick

Why Diamond?

There is great potential for highly sensitive sensors in the extreme fragility of quantum states, which allows the measurement of magnetism and electric fields. The diamond crystal lattice offers a perfect host material for solid-state qubits, as it provides a low-noise background. It must be noted, however, that this fragility also offers some challenges with respect to process development.

Of course, in an ideal world, quantum states would be isolated from the surrounding environment, but a degree of external interaction is required for measurement. This fine line marks the delicate balance between control and interaction that is increasingly required to allow scientists to take full advantage of this exciting technology.

Element Six provides unrivaled diamond expertise and advanced materials to its global network, working closely with partners, including the University of Warwick, to scale this advanced technology to workable, real-life solutions.

What is a Diamond Nitrogen Vacancy (NV) Center?

In the 1990s and early 2000s, a series of pioneering studies demonstrated that a defect in diamond, known as the nitrogen vacancy centre, has a quantum spin that can be both manipulated and read out at room temperature by using simple optical techniques.

Such quantum defects can be introduced into the material with a high degree of precision thanks to synthetic diamond manufactured through the chemical vapour deposition (CVD) method.

The creation of NV centers is facilitated by removing two adjacent carbon atoms from the diamond lattice, one of which is replaced with a nitrogen atom, leaving the other one empty. This forms the titular vacancy.

The NV has an electronic spin that is highly sensitive to magnetic fields, providing the perfect solution for highly accurate magnetometry. The simple utility of this platform is what makes it so powerful: the electronic spin can be manipulated just by shining a green laser onto the material, and subsequently, the spin can be measured through the intensity of the red fluorescence emitted.

It has been demonstrated that NV electron spins can store quantum information for over 1 ms at room temperature. Although some applications require groups of multiple NV centers, such a method of detection and alignment as this can also work for single NV centers, which facilitates new possibilities for unprecedented spatial resolution and nanoscale sensitivity.

About Element Six

Element Six is part of De Beers Group and is a world-leading manufacturer of synthetic diamond, which has been engineered to contain NV centers using the chemical vapor deposition (CVD) method.

Element Six, in collaboration with commercial groups and researchers around the world, has developed, manufactured and supplied the award-winning quantum grade diamond which has been used in many of the most significant breakthroughs in quantum technology.

About the University of Warwick

The University of Warwick, in partnership with UKRI, The Royal Society and The Royal Academy of Engineering, builds quantum science and technology. Notable partners have been the NQIT Hub (Networked Quantum Information Technologies), the Hub in Quantum Computing and Simulation (QCS), and the Quantum Sensors Hub, which belong to the UK National Quantum Technologies Programme.

One of the world’s leading research institutions, the University of Warwick is consistently ranked in the UK’s top 10 and global top 100 universities. Warwick has established a reputation of scientific excellence since its foundation in 1965, specifically through the Faculty of Science, Engineering and Medicine (which includes WMG and the Warwick Medical School).

A truly global university, Warwick has been in the top 30 for global employability in the QS World University Rankings and was named in the top 25 of the Times Higher Education’s Most International University rankings.

Further Reading

- The diamond quantum revolution - M Markham & DJ Twitchen, 2020, PhysicsWorld

- Characterisation of CVD diamond with high concentrations of nitrogen for magnetic-field sensing applications - AM Edmonds et al, 2021, Materials for Quantum Technology 1, 025001

- Imaging damage in steel using a diamond magnetometer - LQ Zhou et al, 2021, Physical Review Applied 15, 024015

- Sub-nanotesla magnetometry with a fibre-coupled diamond sensor - RL Patel et al, 2020 Physical Review Applied 14, 044058

This information has been sourced, reviewed and adapted from materials provided by Element Six.

For more information on this source, please visit Element Six.