Nitrogen is the atmosphere of choice for printed circuit board soldering as it is plentiful, non-conductive, and chemically inert. Nitrogen can help printed circuit board manufacturers increase their productivity, reduce faults, and save costs.

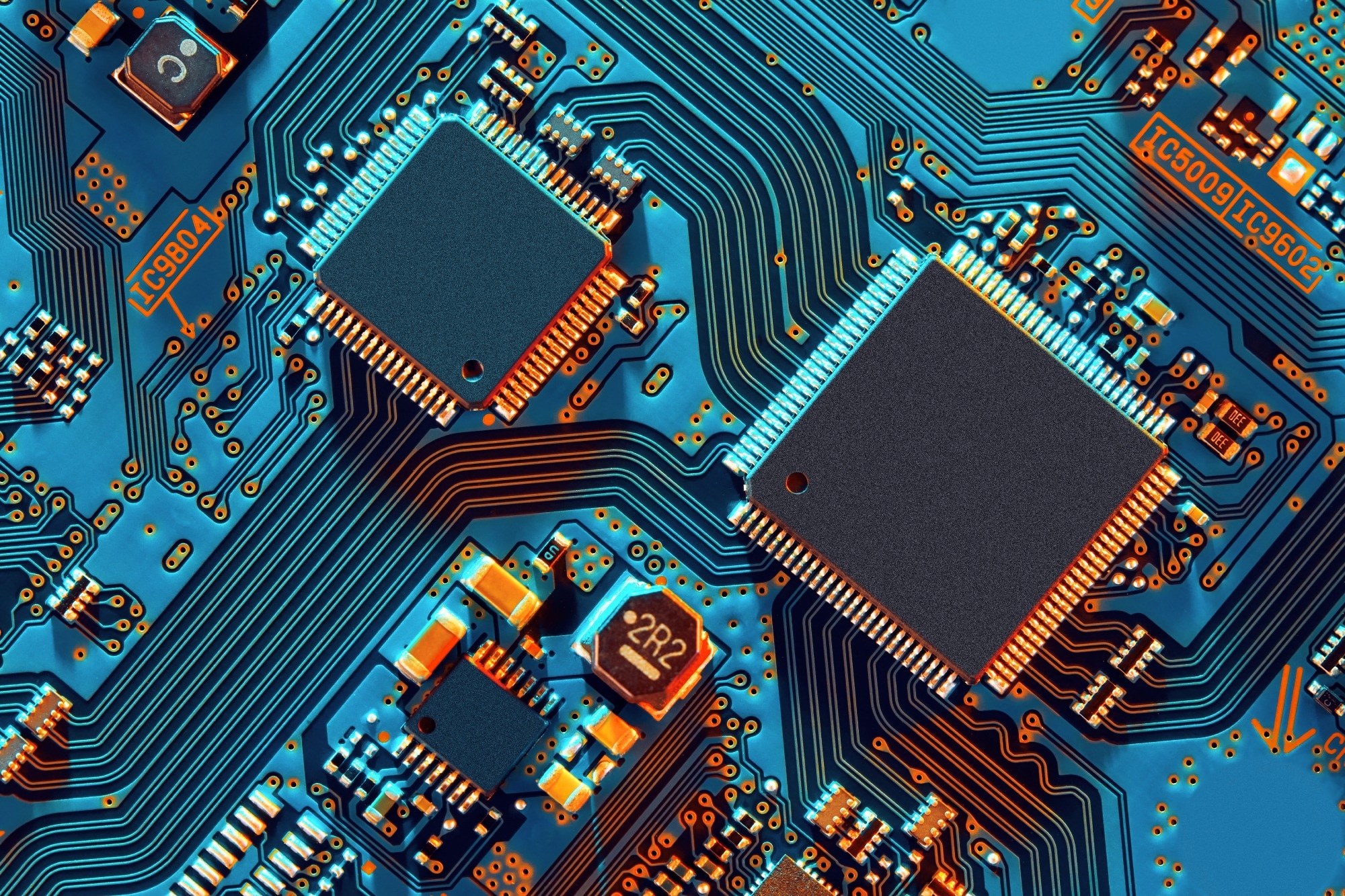

Image Credit: raigvi/Shutterstock.com

Printed circuit boards (PCBs) have become the foundation of contemporary electronics, appearing in nearly all electronic equipment. The worldwide printed circuit board industry is continually expanding; in 2020, the value was $12.1 billion, and by 2026,1 it is expected to reach $20.3 billion.

Electronic components are attached to the surface of PCBs, which are made up of laminated insulating and conducting layers. Conducting layers are carved into meticulously planned tracks, while insulating layers make up the majority of the circuit board.

To build functioning circuity, electronic components are soldered to these tracks in predetermined places.

PCB assembly, or the process of depositing and soldering components to a laminated substrate, is characteristically accomplished using either “through-hole technology”, in which component electrodes are inserted into holes, or “surface mount technology”, wherein components are stacked on top of the PCB and momentarily held in place by solder paste.

This process is followed by soldering. Soldering can be accomplished in a number of various techniques, the most popular of which are bulk wave and reflow.

A regulated atmosphere is necessary during soldering. Reactive gases like oxygen and water vapor can cause rejections by interfering with the solder junctions.

Benefits of Nitrogen in PCB Assembly

The use of nitrogen as an inert atmosphere for electronics assembly is a widely acknowledged solution to these issues. Pure nitrogen is dry, inert, and electrically non-conductive compared to ordinary air. Nitrogen also makes up a larger portion of the atmosphere (78%) than other inert gases, making it significantly more cost-effective.2

An inert nitrogen environment increases solder wetting, extends flux activity, and reduces solder paste oxidation, resulting in higher-quality solder junctions. Furthermore, adopting an inert atmosphere minimizes flux residue and lowers the required process temperatures.3,4

The purity of required nitrogen is determined by the process requirements. As the intricacy of printed circuit boards grows, it is more critical than ever to have dependable and defect-free soldering methods. The use of high-purity nitrogen is a simple technique to ensure good results: by lowering impurity levels, undesirable contamination of solder joints can be avoided.

Air Products offers various grades of nitrogen gas that are suited for PCB assembly. Ultra-high-purity nitrogen guarantees better solder connections, fewer rejects, and less expensive manual PCB rework.

For small-to-medium customers, Air Products offers packs and cylinders; for medium-to-large applications, CryoEase® service offers an easy and compact solution with minimum commitment and cheap expenditure.

Air Products also supply nitrogen in bulk; either in cryogenic tanks or high-pressure gas cylinders for larger-scale consumers. They have experience in delivering on-site nitrogen generating systems.

To find out more about Air Products nitrogen products and services for PCB manufacturing, get in touch with a member of the team.

References and Further Reading

- Technavio. Printed Circuit Board (PCB) Market Size to Grow by USD 12.86 Bn | Rising Adoption Of Smartphones to Boost Market Growth | 17,000+ Technavio Research Reports. https://www.prnewswire.com/news-releases/printed-circuit-board-pcb-market-size-to-grow-by-usd-12-86-bn--rising-adoption-of-smartphones-to-boost-market-growth--17-000-technavio-research-reports-301434184.html.

- Laboratory, S. U. H. I. on E. C. A. A. F.-P. S. B. A. B., NASA’s Jet Propulsion. The Atmosphere: Getting a Handle on Carbon Dioxide. Climate Change: Vital Signs of the Planet https://climate.nasa.gov/news/2915/the-atmosphere-getting-a-handle-on-carbon-dioxide.

- Dong, M., Wang, Y., Cai, J., Feng, T. & Pu, Y. Effects of nitrogen on wettability and reliability of lead-free solder in reflow soldering. (2009) doi:10.1109/ICEPT.2009.5270776.

- Arslanian, G., Lin, M. & Wressel, A. Effects of Solder Reflow Conditions on the Assembly of Electronics Packaging and Printed Circuit Boards. https://www.airproducts.co.uk/-/media/airproducts/files/en/450/450_11_001_glb-effects-of-solder-reflow-conditions-elec-packaging-printed-circuit-boards.pdf.

This information has been sourced, reviewed and adapted from materials provided by Air Products PLC.

For more information on this source, please visit Air Products PLC.